A kind of general epoxy primer and its preparation method and application

A primer and epoxy technology, used in primers, epoxy coatings, coatings, etc., can solve the problems of poor adhesion and long adaptation period, and achieve the purpose of improving adhesion, promoting improvement and promoting adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

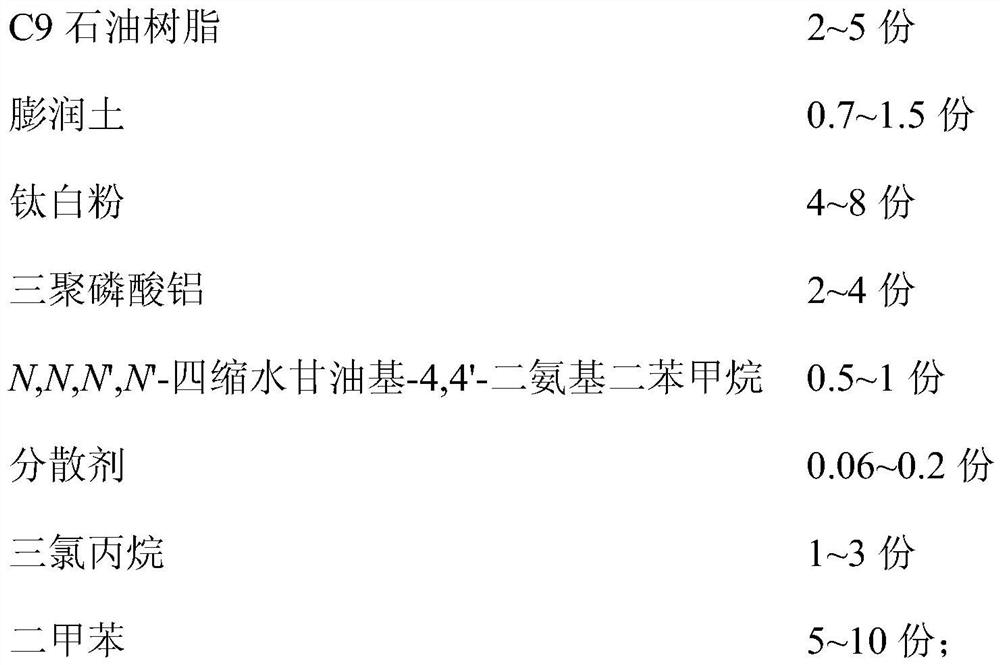

[0057] The present embodiment provides a kind of epoxy general primer, comprises A component and B component, and wherein the mass ratio of A component and B component is 5.4:1, and A component comprises following components:

[0058]

[0059] Component B includes the following components in parts by weight:

[0060]

[0061] The preparation method is:

[0062] (1) Prepare a solution after dissolving epoxy resin, C9 petroleum resin, trichloropropane and xylene at 45°C for 20 minutes;

[0063] (2) Add polyoxyethylene fatty alcohol ether, bentonite, and titanium dioxide to the mixed solution obtained in step (1), and finally slowly add aluminum tripolyphosphate and N,N,N',N'-tetraglycidyl-4 , 4'-diaminodiphenylmethane, stirring at a rotation speed of 950r / min, and dispersing at 57°C for 30min to obtain component A;

[0064] (3) Mix the epoxy resin curing agent, dimethylpolysiloxane, 3-methylphenol and xylene uniformly according to the weight ratio to obtain component B; ...

Embodiment 2

[0067] The present embodiment provides a kind of epoxy universal primer, comprises A component and B component, and wherein the mass ratio of A component and B component is 5.2:1, and A component comprises following components:

[0068]

[0069] Component B includes the following components in parts by weight:

[0070]

[0071] The preparation method is:

[0072] (1) Prepare a solution after dissolving epoxy resin, C9 petroleum resin, trichloropropane and xylene at 50°C for 30 minutes;

[0073] (2) Add polyoxyethylene alkylphenol ether, bentonite, and titanium dioxide to the mixed solution obtained in step (1), and finally slowly add aluminum tripolyphosphate and N,N,N',N'-tetraglycidyl- 4,4'-Diaminodiphenylmethane, stirred at a rotation speed of 1000r / min, dispersed at 58°C for 40min to obtain component A;

[0074] (3) Mix the epoxy resin curing agent, dimethylpolysiloxane, 3-methylphenol and xylene uniformly according to the weight ratio to obtain component B;

[00...

Embodiment 3

[0077] The present embodiment provides a kind of epoxy universal primer, comprises A component and B component, and wherein the mass ratio of A component and B component is 5.6:1, and A component comprises following components:

[0078]

[0079] Component B includes the following components in parts by weight:

[0080]

[0081] The preparation method is:

[0082] (1) Prepare a solution after dissolving epoxy resin, C9 petroleum resin, trichloropropane and xylene at 40°C for 10 minutes;

[0083] (2) Add methyl phosphate, bentonite, and titanium dioxide to the mixed solution obtained in step (1), and finally slowly add aluminum tripolyphosphate and N,N,N',N'-tetraglycidyl-4,4' - Diaminodiphenylmethane, stirred at a rotation speed of 900r / min, dispersed at 56°C for 20min to obtain component A;

[0084] (3) Mix the epoxy resin curing agent, dimethylpolysiloxane, 3-methylphenol and xylene uniformly according to the weight ratio to obtain component B;

[0085] (4) Mix compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com