U-shaped bubble ring generation device and method

A generating device and foam technology, which is applied in earthwork drilling, cleaning equipment, mining fluids, etc., can solve problems such as the risk of condensation pipes, pipeline corrosion and scaling, and high energy consumption of heating methods, so as to improve transmission efficiency and slow down heat Exchange, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

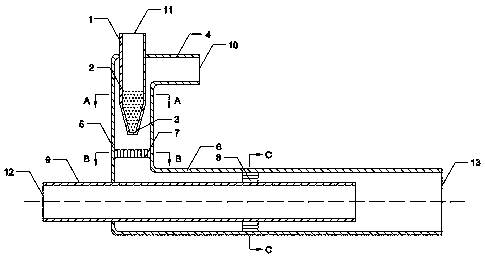

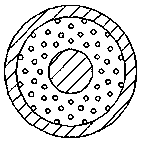

[0018] The invention provides a U-shaped foam ring generating device, which comprises: a foam liquid pipe, a U-shaped pipe, an oil inlet pipe, a grid, and a drainage plate. The foam liquid pipe is composed of two parts, that is, the liquid inlet pipe (1) and the reducer pipe (3) with perforation (2); the U-shaped pipe is composed of three parts, namely, the air inlet pipe (4), the mixing pipe (5 ) and the loop pipe (6). Specifically, there are two types of pipes for the above-mentioned foam liquid pipe. The end of the reducer (3) is sealed, and its conical angle is 30°, which is beneficial for the foam liquid to flow from the perforation along the direction perpendicular to the wall of the reducer (3). (2) Spray out evenly and fully mix with air; the grid (7) makes the foam evenly dispersed in the annular channel; a certain length sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com