Accumulator type electronic control fuel injection system with variable supercharge ratio

A technology of fuel injection system and supercharging ratio, which is applied to fuel injection devices, charging systems, engine components, etc., can solve the problems of difficult flexible control of fuel injection rate, decrease of uniformity and stability of fuel injection process, etc. Achieve the effect of improving economy and power, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

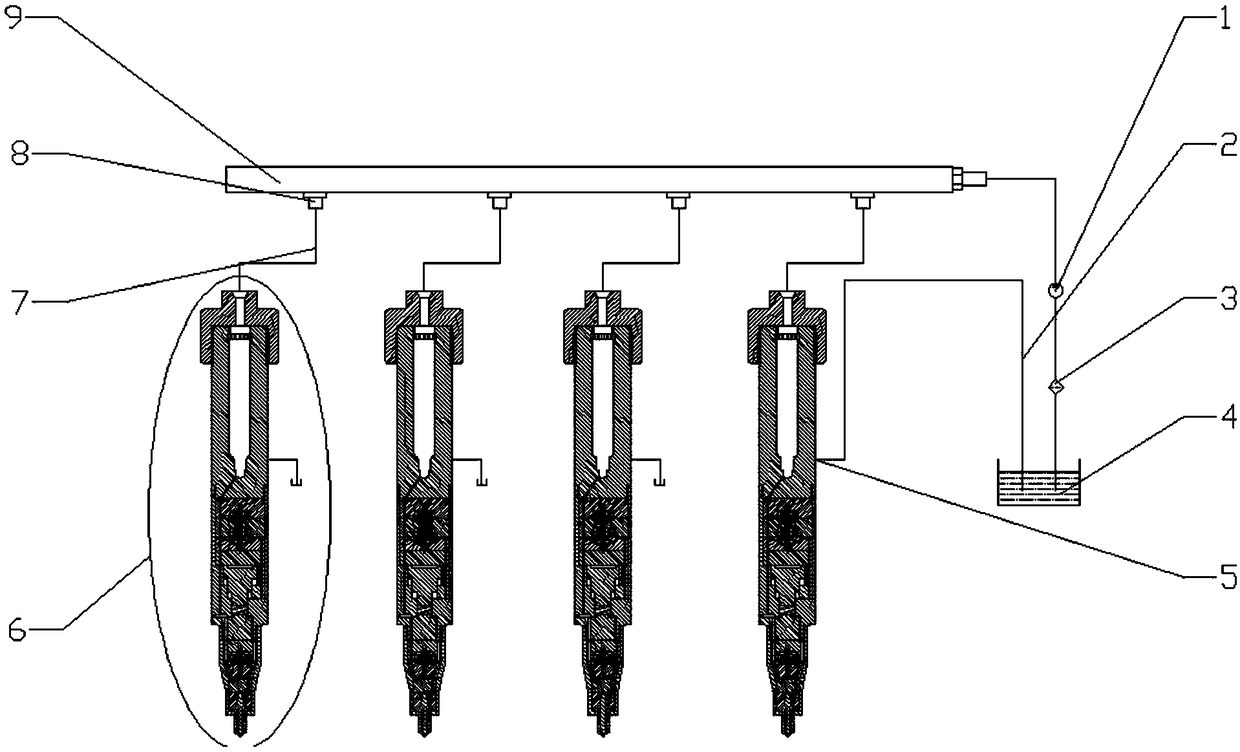

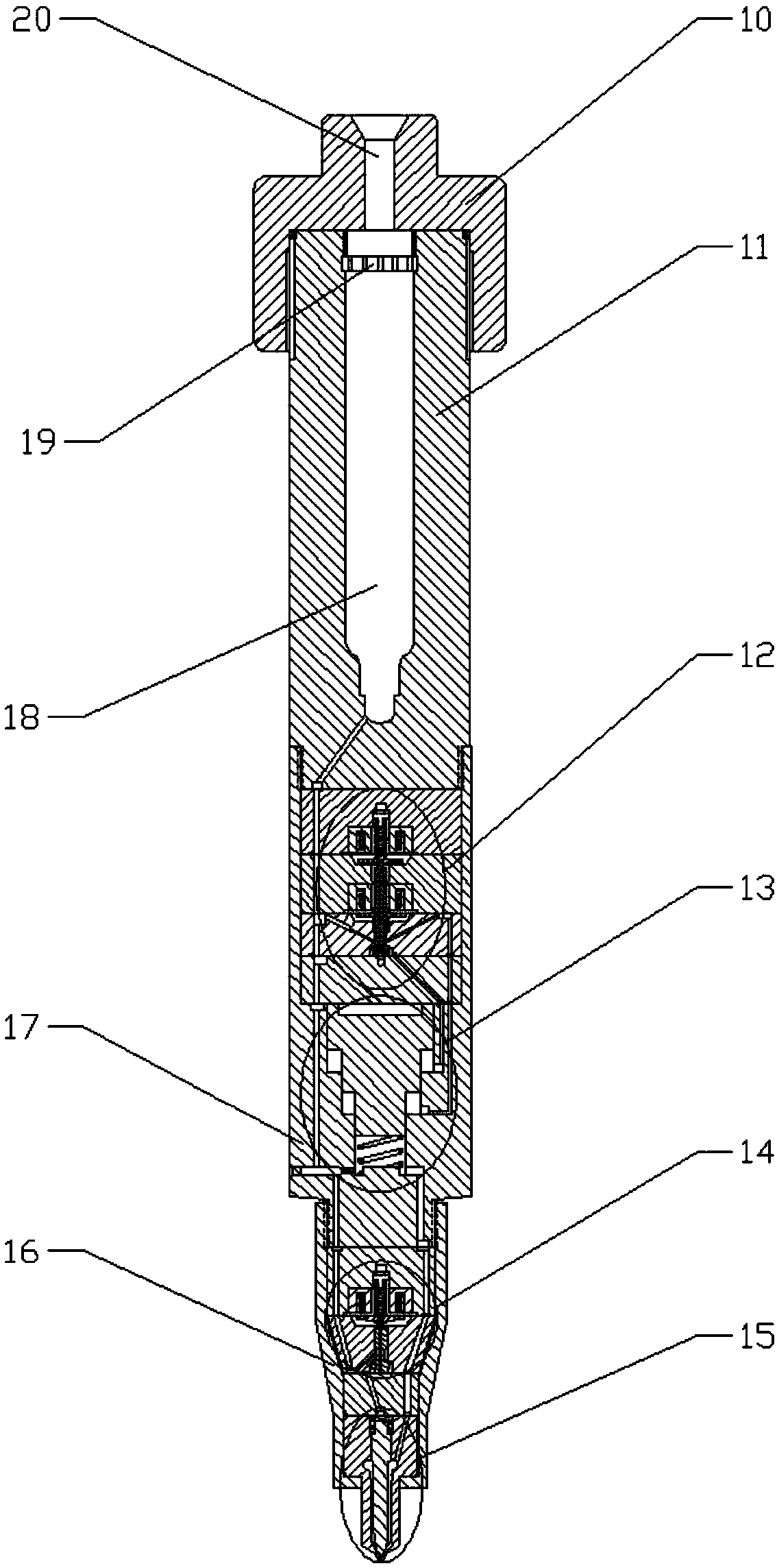

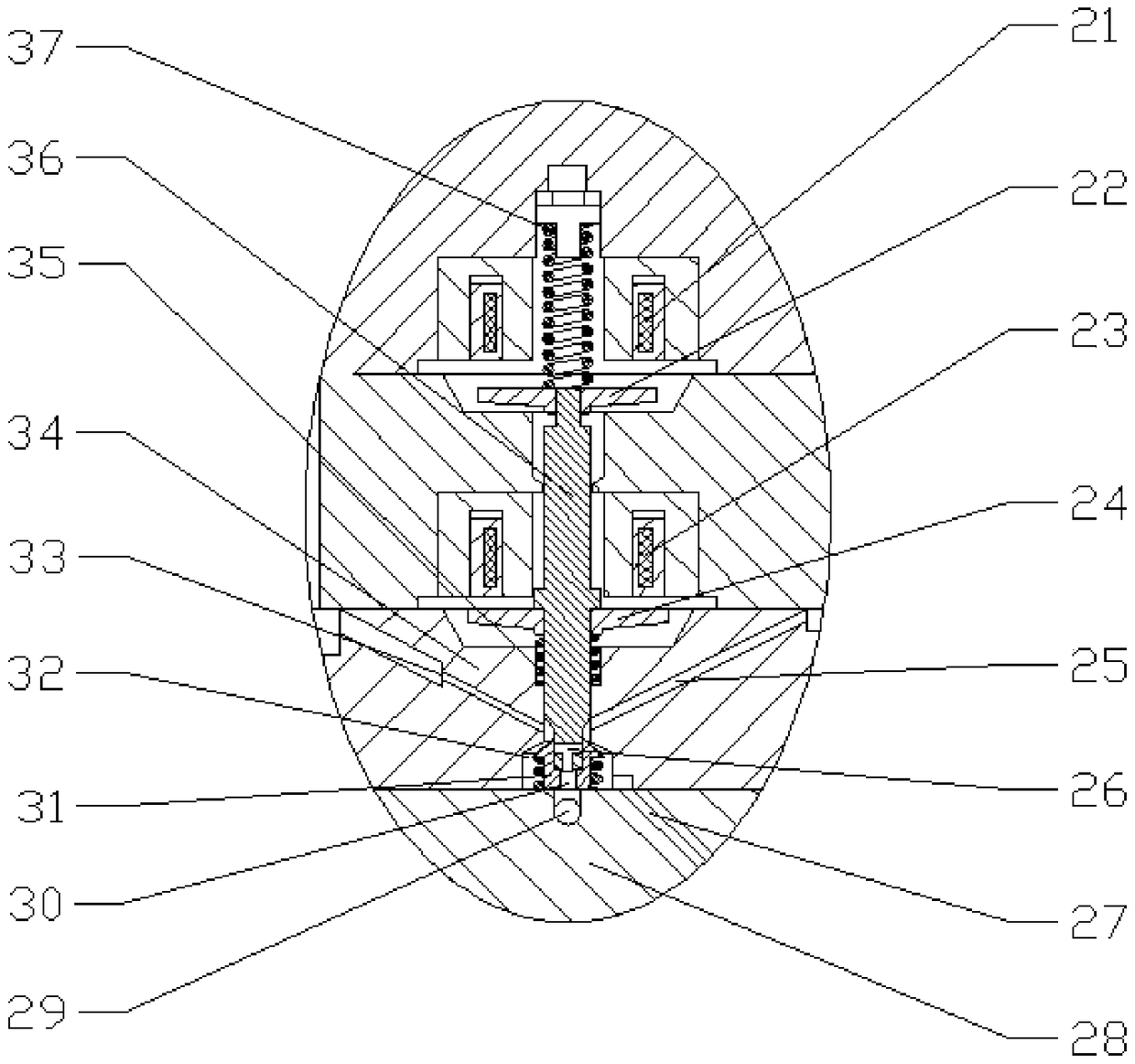

[0024] combine Figure 1-6 , the variable boost ratio accumulator pressure electronically controlled fuel injection system of the present invention comprises a common rail pipe 9, a high pressure oil pipe 7, a high pressure oil pump 1, a filter 3, a fuel tank 4, an oil return pipe 2 and a fuel injector 6, and the common rail pipe The right end of 9 is connected with high-pressure oil pump 1, filter 3 and oil tank 4 respectively. There are multiple hydraulic oil outlets 8 on the common rail pipe 9. The number of hydraulic oil outlets 8 is determined according to the number of cylinders of the internal combustion engine. The oil pipe 7 communicates with the fuel inlet 20 opened on the fuel injector 6 , and the low-pressure fuel return port 5 opened on the fuel injector 6 communicates with the fuel tank 4 through the oil return pipe 2 . The fuel injector 6 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com