Multilayer composite aliphatic polyketone microporous membrane and preparation method thereof

An aliphatic polyketone and multi-layer composite technology, which is applied to structural parts, electrical components, battery pack parts, etc., can solve problems such as poor thermal dimensional stability at high temperature, low closed cell temperature of the isolation film, and increased safety hazards, etc. , achieve high membrane rupture temperature, closed cell temperature and high membrane rupture temperature, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

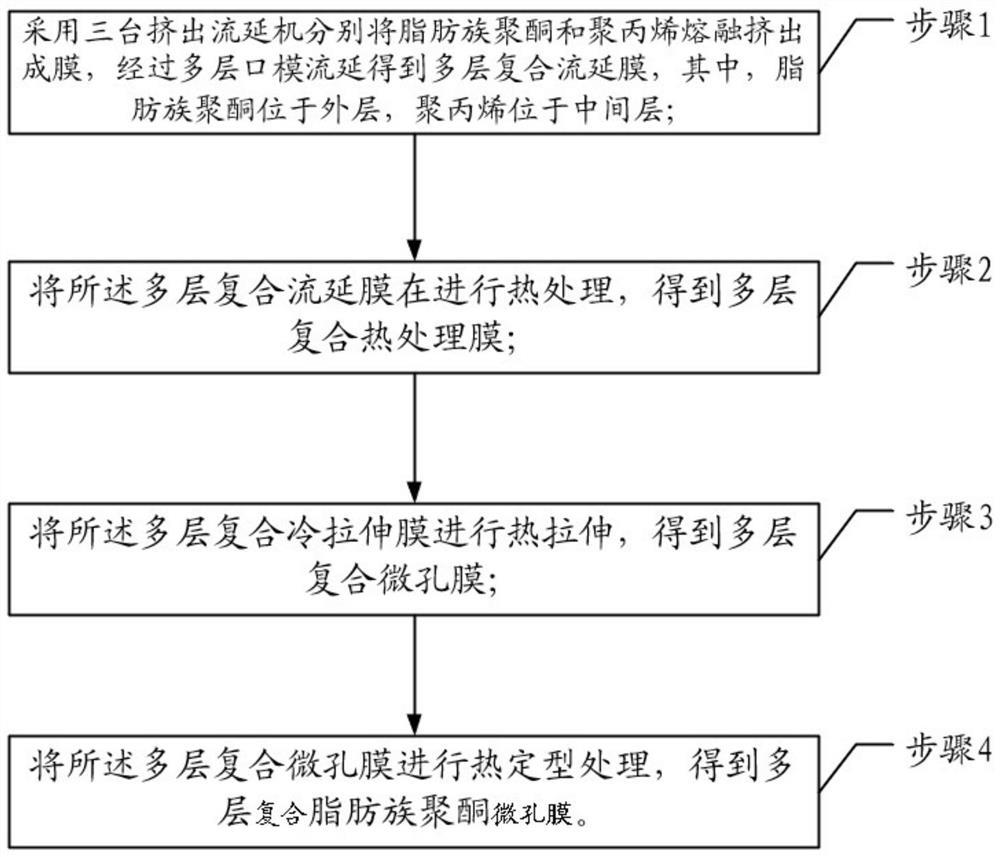

[0050] This embodiment provides the first specific implementation scheme, and the steps are as follows:

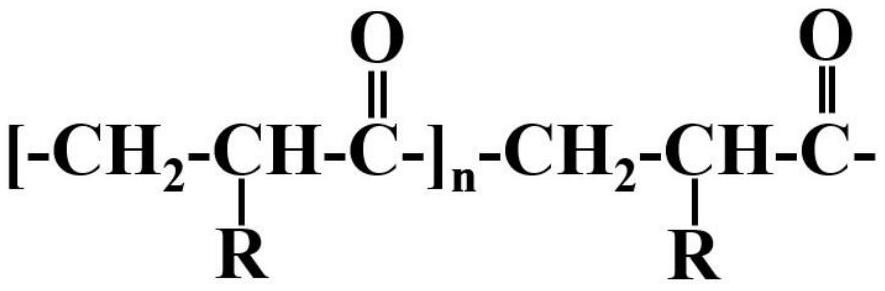

[0051] Add polypropylene and aliphatic polyketone to different single-screw extruders for melting, and co-extrude and cast a film through a multi-layer die to obtain a multi-layer composite cast film, in which the aliphatic polyketone is located in the outer layer , polypropylene is located in the middle layer, and the structure of the multilayer composite cast film is aliphatic polyketone layer-polypropylene layer-aliphatic polyketone layer; the melt index of aliphatic polyketone is 6g / 10min, and the melt index of polypropylene is 6g / 10min; the temperature of the multilayer die is 220°C.

[0052] The multi-layer composite cast film was heat-treated in a blast oven at 130° C. for 60 minutes to obtain a multi-layer composite heat-treated film. The multi-layer composite heat-treated film was thermally stretched at 145° C., the thermal stretch rate was 10 mm / min, and the the...

Embodiment 2

[0054] This embodiment provides the second specific implementation scheme, the steps are as follows:

[0055] Add polypropylene and aliphatic polyketone to different single-screw extruders for melting, and co-extrude and cast a film through a multi-layer die to obtain a multi-layer composite cast film, in which the aliphatic polyketone is located in the outer layer , polypropylene is located in the middle layer, and the structure of the multilayer composite cast film is aliphatic polyketone layer-polypropylene layer-aliphatic polyketone layer; the melt index of aliphatic polyketone is 2g / 10min, and the melt index of polypropylene is 2g / 10min; the temperature of the multilayer die is 240°C.

[0056] The multilayer composite cast film was heat-treated in a blast oven at 150° C. for 10 minutes to obtain a multilayer composite heat-treated film. The multi-layer composite heat-treated film was thermally stretched at 145° C., the thermal stretch rate was 100 mm / min, and the thermal...

Embodiment 3

[0058] This embodiment provides a third specific implementation scheme, the steps are as follows:

[0059] Add polypropylene and aliphatic polyketone to different single-screw extruders for melting, and co-extrude and cast a film through a multi-layer die to obtain a multi-layer composite cast film, in which the aliphatic polyketone is located in the outer layer , polypropylene is located in the middle layer, and the structure of the multilayer composite cast film is aliphatic polyketone layer-polypropylene layer-aliphatic polyketone layer; the melt index of aliphatic polyketone is 3g / 10min, and the melt index of polypropylene is 3g / 10min; the temperature of the multilayer die is 220°C.

[0060] The multilayer composite cast film was heat-treated in a blast oven at 145° C. for 30 minutes to obtain a multilayer composite heat-treated film. The multi-layer composite heat-treated film was thermally stretched at 145° C., the thermal stretch rate was 50 mm / min, and the thermal str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com