Graphene-like framework-loaded single-atom structure material and its preparation method and application

An atomic structure and graphene technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve problems such as obstacles, limitations of active atom catalytic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Weigh 19mmol of zinc acetate and 1mmol of cobalt nitrate and dissolve them in 200mL of ethanol in a water bath at 65°C to form a mixed solution;

[0039] 2) Weigh 40mmol of citric acid monohydrate and dissolve it in 50mL of ethanol, and slowly add it dropwise to the mixed solution of step 1) to produce flocculent gel;

[0040] 3) drying the gel prepared in step 2) at 80°C for 24 hours to obtain a xerogel;

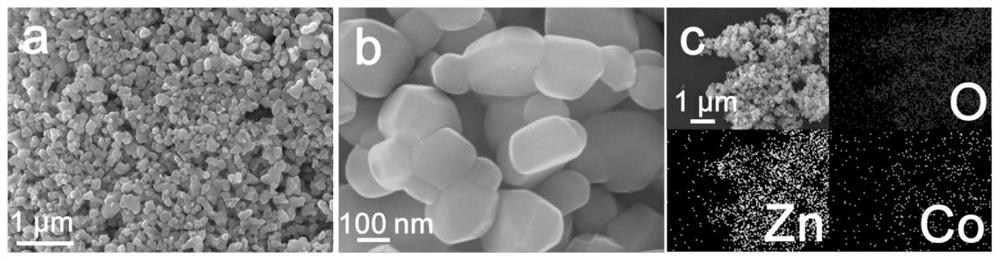

[0041] 4) Dry the dry gel obtained in step 3) in the air at 5°C for min -1 The heating rate is increased to 600 ° C for 6 hours to form Co-doped ZnO nanoparticles;

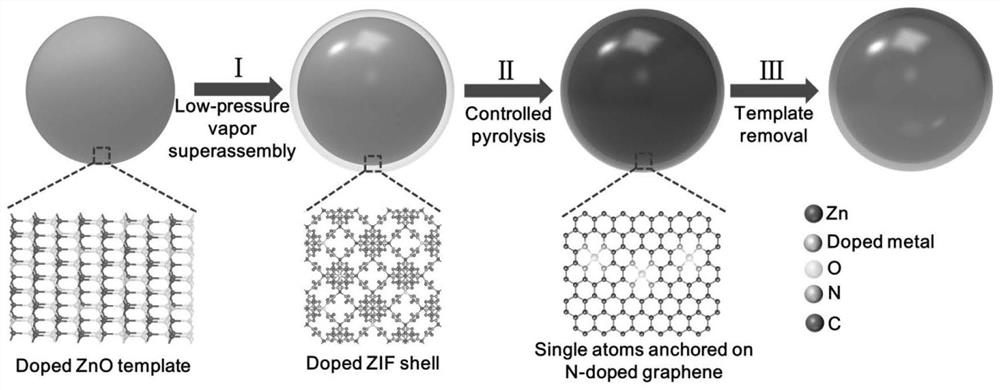

[0042] 5) Weigh 2g of Co-doped ZnO nanoparticles prepared in step 4) and place them in a vacuum oven at the same time as 4g of 2-methylimidazole. Under a pressure of 100Pa, heat up to 140°C and keep for 6h to obtain a metal-organic framework coating. Co-doped ZnO nanoparticle structure;

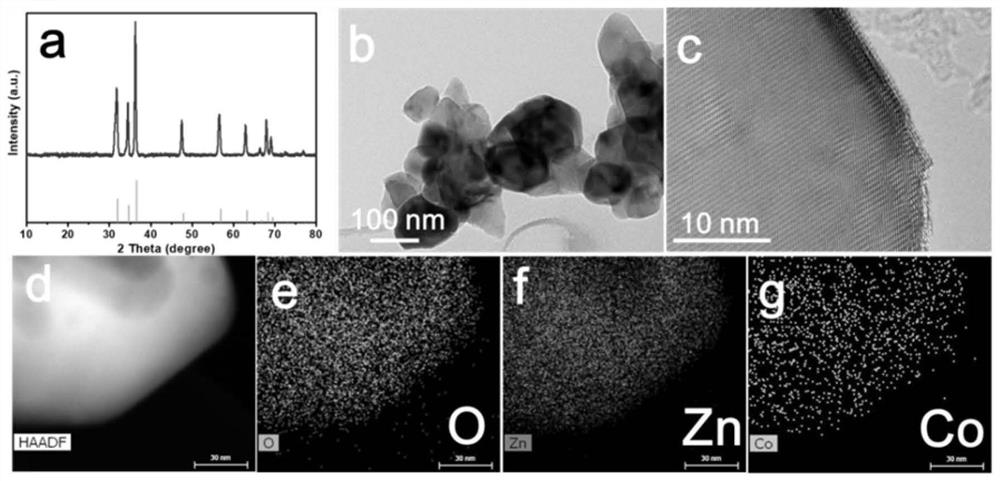

[0043] 6) The metal-organic framework structure obtained in step 5) is coated with Co-doped ZnO nanoparticles i...

Embodiment 2

[0053] 1) Weigh 19mmol of zinc acetate and 1mmol of ferric nitrate and dissolve them in 200mL of ethanol in a water bath at 65°C to form a mixed solution;

[0054] 2) Weigh 40mmol of citric acid monohydrate and dissolve it in 50mL of ethanol, and slowly add it dropwise to the mixed solution of step 1) to produce flocculent gel;

[0055] 3) drying the gel prepared in step 2) at 80°C for 24 hours to obtain a xerogel;

[0056] 4) Dry the dry gel obtained in step 3) in the air at 5°C for min -1 The heating rate is increased to 600 ° C for 6 hours to form Fe-doped ZnO nanoparticles;

[0057] 5) Weigh 2g of the prepared Fe-doped ZnO nanoparticles and 4g of 2-methylimidazole in a vacuum oven at the same time as in step 4). Under the pressure of 100Pa, heat up to 140°C for 6h to obtain metal organic framework coating Fe-doped ZnO nanoparticle structure;

[0058] 6) The metal-organic framework structure obtained in step 5) coated Fe-doped ZnO nanoparticle structure in N 2 at 5°C mi...

Embodiment 3

[0063] 1) Weigh 19mmol of zinc acetate and 1mmol of nickel nitrate and dissolve in 200mL of ethanol in a water bath at 65°C to form a mixed solution;

[0064] 2) Weigh 40mmol of citric acid monohydrate and dissolve it in 50mL of ethanol, and slowly add it dropwise to the mixed solution of step 1) to produce flocculent gel;

[0065] 3) drying the gel prepared in step 2) at 80°C for 24 hours to obtain a xerogel;

[0066] 4) Dry the dry gel obtained in step 3) in the air at 5°C for min -1 The heating rate was increased to 470 ° C for 6 hours to form Ni-doped ZnO nanoparticles;

[0067] 5) Weigh 2g of the prepared Ni-doped ZnO nanoparticles and 4g of 2-methylimidazole in a vacuum oven at the same time as in step 4). Under the pressure of 100Pa, heat up to 140°C and keep it for 6h to obtain metal-organic framework coating Ni-doped ZnO nanoparticle structure;

[0068] 6) Coating the metal-organic framework structure obtained in step 5) with Ni-doped ZnO nanoparticles on N 2 at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com