A kind of magnesium secondary battery and preparation method thereof

A magnesium secondary battery and magnesium salt technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of rate performance to be improved, poor kinetics, etc., and achieve good industrialization prospects and technological processes Ease of control and high theoretical specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Prepare iodine-containing cathode material:

[0036] Mix 5 g of nanoporous carbon with 3 g of iodine, raise the temperature to 145 °C in vacuum at a heating rate of 1 °C / min, keep it for 1 h, and then cool down to room temperature at a cooling rate of 1 °C / min to obtain an iodine-containing positive electrode material, its SEM topography, see figure 1 .

[0037] 2) Prepare positive electrode:

[0038] The prepared iodine-containing positive electrode material was uniformly mixed with the binder polytetrafluoroethylene in a mass ratio of 8:2, and placed at 60° C. for 10 h under vacuum conditions to obtain a positive electrode.

[0039] 3) Preparation of electrolyte:

[0040] Mg(HDMS) 2 Dissolve in tetraethylene glycol dimethyl ether to make Mg(HDMS) 2 The concentration in the solution is 0.1 Mol / L, and the additive LiTFSI is added under stirring 2 , LiTFSI 2 with Mg(HDMS) 2 The molar ratio is 5:1, fully stir and mix evenly, then add MgCl 2 , MgCl 2 with Mg(H...

Embodiment 2

[0044] 1) Prepare iodine-containing cathode material:

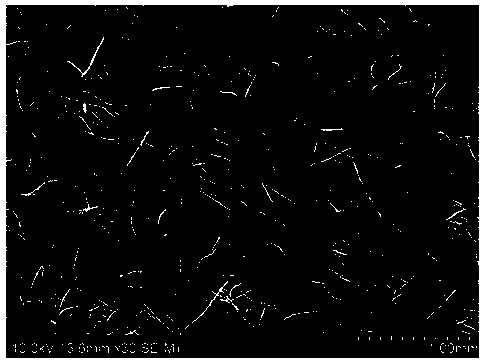

[0045] Combine 8g of porous flexible carbon cloth with 4g of I 2 Mix, heat up to 160°C with a heating rate of 2°C / min in an Ar gas atmosphere, keep for 30h, and then cool down to room temperature at a cooling rate of 1°C / min to obtain an iodine-containing positive electrode material, and its SEM morphology Figure, see figure 2 .

[0046] 2) Prepare positive electrode:

[0047] The obtained iodine-containing positive electrode material was placed at 80°C for 20h under vacuum conditions to obtain the positive electrode;

[0048] 3) Preparation of electrolyte:

[0049] 25g magnesium salt Mg(HDMS) 2 Dissolved in 20ml TEGDME solvent, stirred for 12h, named solution 1; 6.8gMgCl 2 Dissolve in 10ml TEGDME solvent, stir for 12h, named as solution 2; slowly add solution 2 into solution 1, stir for 24h, named as solution 3, add 18.6g AlCl 3 The powder was added to solution 3, and fully stirred for 24 hours to obtain an electro...

Embodiment 3

[0055] 1) Prepare iodine-containing cathode material:

[0056] Dissolve 6g of iodine in 5mL of ethanol, add 3.5g of carbon nanotubes after fully stirring, continue to stir for 2h, take it out, and place it at 60°C for 5h under vacuum conditions to obtain an iodine-containing positive electrode material;

[0057] 2) Prepare positive electrode:

[0058] The obtained iodine-containing positive electrode material is uniformly mixed with the binder PTFE in a mass ratio of 6:4, and placed at 60° C. for 10 h under vacuum conditions to obtain the positive electrode;

[0059] 3) Preparation of electrolyte:

[0060] MgTFSI 2 Dissolved in dimethylformamide to make MgTFSI 2 The concentration in the solution is 10 Mol / L, and the additive MgCl is added under stirring 2 , MgCl 2 with MgTFSI 2 The molar ratio of the mixture is 2:1, fully stirred and mixed evenly to obtain the electrolyte;

[0061] 4) In a glove box filled with argon gas, the positive electrode, magnesium strip negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com