A pulsating high-speed jet impacting plate connection method and device

A technology of high-speed jet and plate connection, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low connection strength, change of material structure, damage of connection position, etc., to ensure integrity and sealing, and improve plasticity Formability, effect of reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

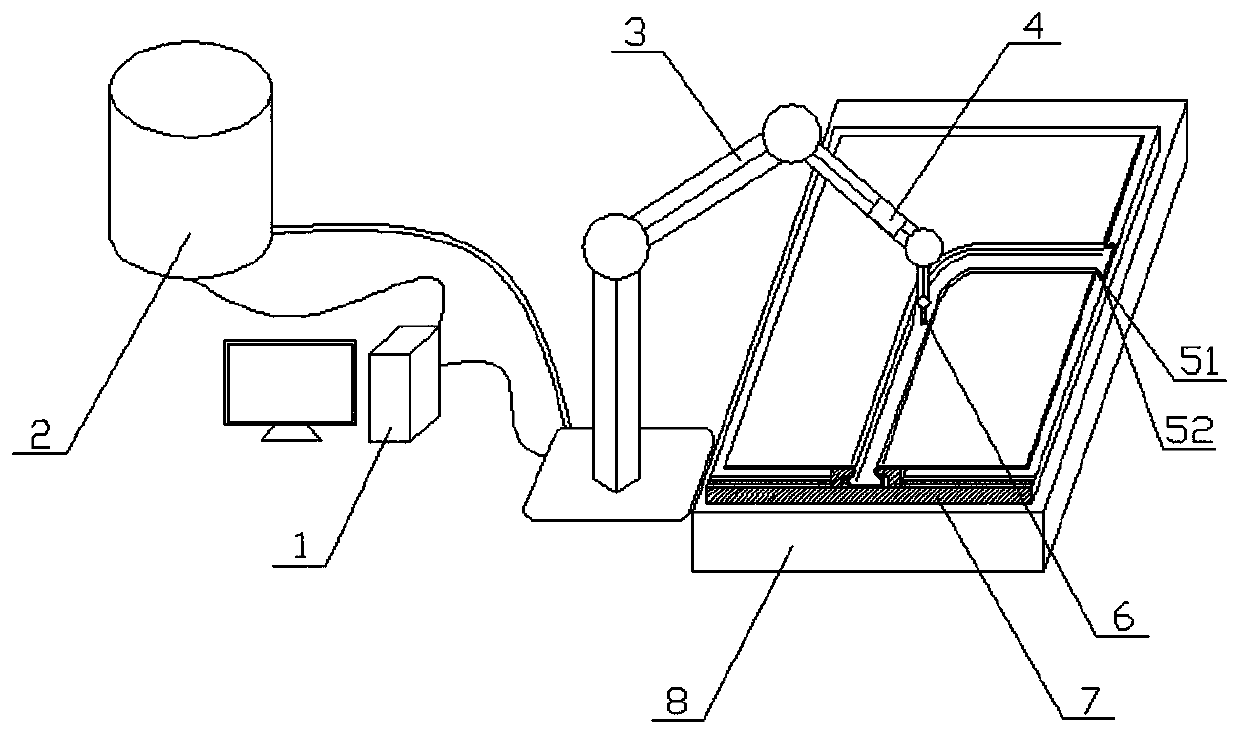

[0047] Such as Figure 1-3 As shown, a pulsating high-speed jet impact plate connecting device includes a control system 1, a high-pressure water pump 2, a joint robot 3, a pulsating loading device 4, a nozzle 6, a mold 7, a workbench 8 and a forming cavity 9.

[0048] The control system 1, the high-pressure water pump 2, and the articulated robot 3 are connected sequentially. The pulsation loading device 4 is installed in the articulated robot 3 and is close to the working end 31. The high-pressure water pump 2 is connected to a water source. At the same time, the control system 1 is connected to the articulated robot 3, the working end 31 of the articulated robot 3 communicates with the nozzle 6, and the control system 1 controls the trajectory and angle of the nozzle by controlling the working end of the articulated robot.

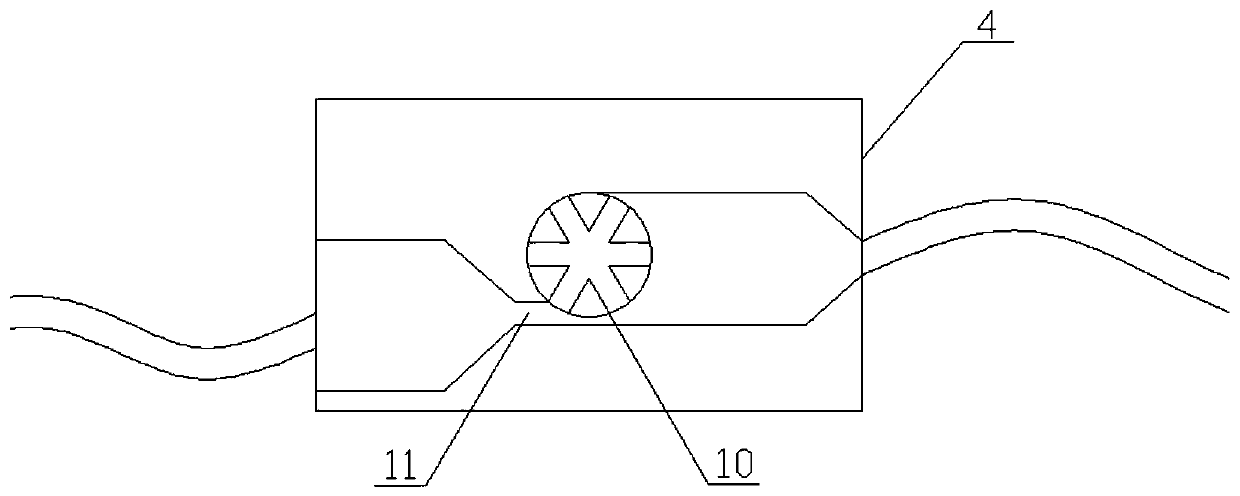

[0049] The pulsating loading device includes an impeller 10 and a water spray pipe 11. The water spray pipe 11 is aligned with the blades of the impell...

Embodiment 2

[0052] The method for connecting plates using the pulsating high-speed jet impacting plate connecting device described in Example 1 comprises the following steps:

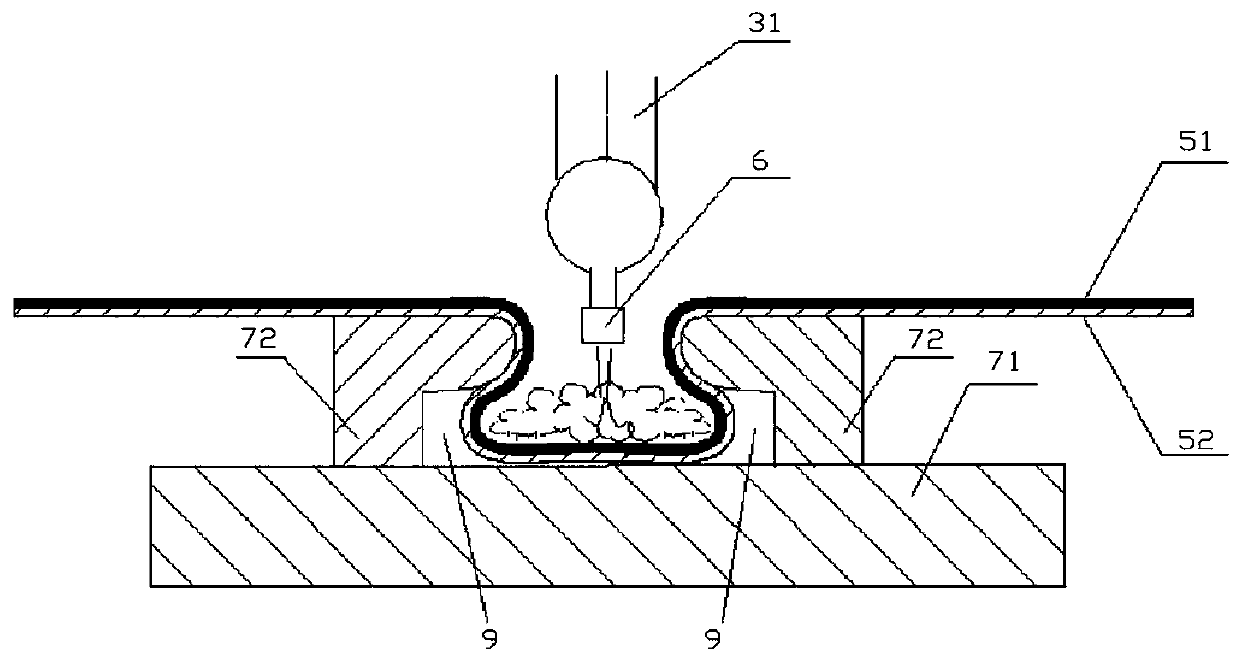

[0053] (1) The mold 7 is fixed on the workbench 8, and the upper plate 51 and the lower plate 52 to be connected, wherein the material of the upper plate and the lower plate are SS304 stainless steel with a thickness of 0.15mm, are superimposed and placed on the mold 7 on two L-shaped brackets;

[0054] (2) Set the clamping angle and motion track of the joint at the working end 31 of the joint robot 3, so that the high-speed jet nozzle 6 can move the upper plate 51 and the lower plate 52 relative to each other according to the set angle and track.

[0055] (3) Set the pressure of the initial flow of water produced by the high-pressure pump 2 through the control system 1. The greater the thickness of the plate, the greater the initial flow pressure required, and then the pressure in the high-pressure water pump is s...

Embodiment 3

[0060] The method for connecting plates using the pulsating high-speed jet impacting plate connecting device described in Example 1 comprises the following steps:

[0061] (1) The mold 7 is fixed on the workbench 8, and the upper plate 51 and the lower plate 52 to be connected, wherein the material of the upper plate and the lower plate are SS304 stainless steel with a thickness of 0.2 mm, are placed on the mold 7 after being stacked together. on two L-shaped brackets;

[0062] (2) Set the clamping angle and motion track of the joint at the working end 31 of the joint robot 3, so that the high-speed jet nozzle 6 can move the upper plate 51 and the lower plate 52 relative to each other according to the set angle and track.

[0063] (3) Set the pressure of the initial flow of water produced by the high-pressure pump 2 through the control system 1. The greater the thickness of the plate, the greater the initial flow pressure required, and then the pressure in the high-pressure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com