Preparation method of anti-electromagnetic radiation polyurethane foam

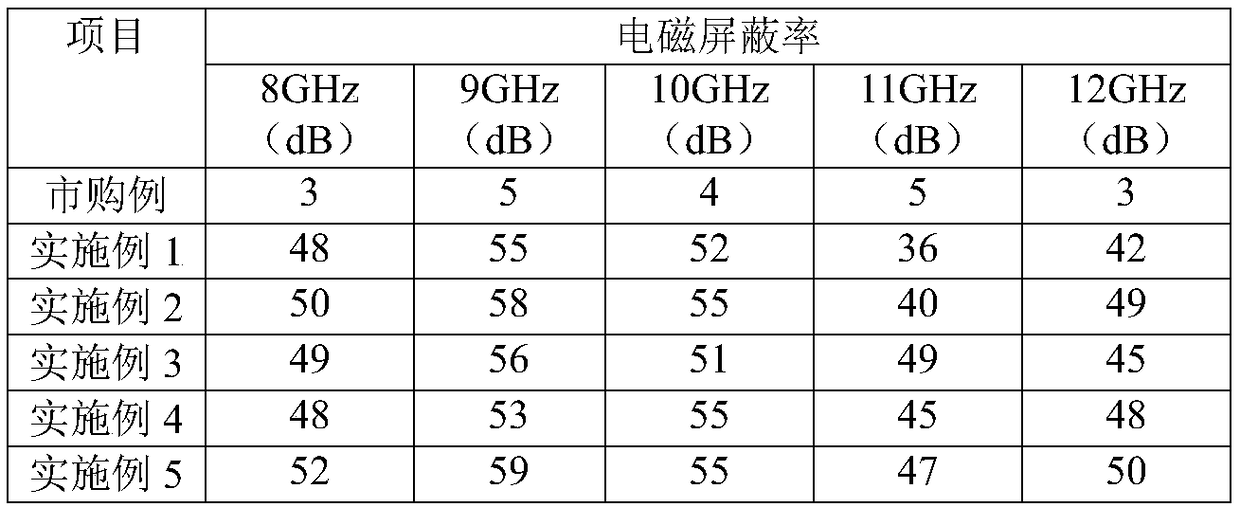

A technology of polyurethane foam and anti-electromagnetic radiation, applied in the field of preparation of anti-electromagnetic radiation polyurethane foam, can solve the problems of low electromagnetic shielding efficiency, poor anti-electromagnetic radiation ability, high cost, etc., achieve low cost, reduce mixing performance, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of anti-electromagnetic radiation polyurethane foam, described preparation method comprises the following steps:

[0038] (1) Preparation of siloxane-modified phthalic anhydride polyester polyol:

[0039] (1.1) Preparation of silicone-modified polyol: Weigh 100 parts of propylene glycol in parts by weight, then add 5 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 0.5 part of glacial acetic acid and water 10 parts, and then stirred and reacted at 40°C for 2 hours, and evaporated under reduced pressure to remove the water and the small molecular substances generated by the reaction to obtain a silicone-modified polyol;

[0040](1.2) Polyester polyol prepolymerization: Weigh 100 parts of silicone-modified polyol obtained in step (1.1) and 45 parts of phthalic anhydride in parts by weight, stir evenly and raise the temperature to 135°C , after stirring and reacting for 3 hours, the prepolymerization step was compl...

Embodiment 2

[0049] A kind of preparation method of anti-electromagnetic radiation polyurethane foam, described preparation method comprises the following steps:

[0050] (1) Preparation of siloxane-modified phthalic anhydride polyester polyol:

[0051] (1.1) Preparation of silicone-modified polyol: Weigh 100 parts of propylene glycol in parts by weight, then add 10 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 2 parts of glacial acetic acid and water 15 parts, then stirred and reacted at 60°C for 5 hours, and evaporated under reduced pressure to remove the water and the small molecular substances generated by the reaction to obtain a silicone-modified polyol; (1.2) Polyester polyol prepolymerization: according to parts by weight Count and weigh 100 parts of silicone-modified polyol and 80 parts of phthalic anhydride obtained in step (1.1), stir evenly, raise the temperature to 185°C, stir and react for 5 hours until the acid value is 30mgKOH / When the prep...

Embodiment 3

[0060] A kind of preparation method of anti-electromagnetic radiation polyurethane foam, described preparation method comprises the following steps:

[0061] (1) Preparation of siloxane-modified phthalic anhydride polyester polyol:

[0062] (1.1) Preparation of silicone-modified polyol: Weigh 100 parts of propylene glycol in parts by weight, then add 8 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 1 part of glacial acetic acid and water 12 parts, and then stirred and reacted at 50°C for 3 hours, and evaporated under reduced pressure to remove the water and the small molecular substances generated by the reaction to obtain a silicone-modified polyol;

[0063] (1.2) Polyester polyol prepolymerization: Weigh 100 parts of silicone-modified polyol obtained in step (1.1) and 75 parts of phthalic anhydride in parts by weight, stir evenly and raise the temperature to 155°C , after stirring and reacting for 4 hours, the prepolymerization step was comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com