Modified composite calcium sulfonate lubricating grease composition and preparation method thereof

A compound calcium sulfonate lubricating grease and the technology of synthesizing calcium sulfonate, applied in the field of lubricating grease, can solve the problems of unfinished amorphous calcium carbonate, etc., achieve good high-temperature anti-oxidation life, excellent extreme pressure and anti-wear performance, extreme pressure resistance grinding excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

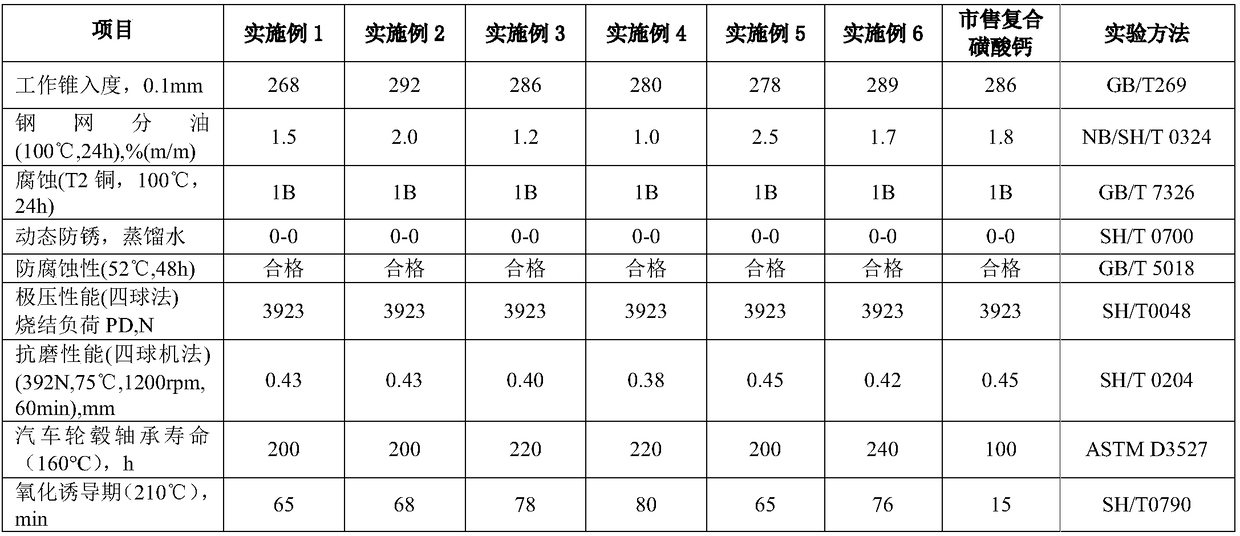

Examples

Embodiment 1

[0031] The formula components and percentages of compound calcium sulfonate grease: 51% high base value synthetic calcium sulfonate, 8.5% high base value calcium salicylate, conversion agent (acetic acid, isopropanol, water mass ratio of 1 :2:4) 4%, calcium hydroxide 1%, compounding agent (mass ratio of boric acid and lauryl hydroxystearic acid is 1:1) 4%, octylbutyl diphenylamine 0.5%, 31% base oil.

[0032] Put the mixture of high base value synthetic calcium sulfonate, high base value calcium salicylate, part of the base oil (30% of the total base oil) and conversion agent into the reaction kettle, stir and heat to 70 ° C, keep the temperature for 90 minutes, and complete Calcium carbonate crystal form transformation, heating up to 95°C, adding calcium hydroxide and compounding agent for compounding, saponification and constant temperature reaction for 60 minutes; after saponification, heating up to 190°C, lowering to 80°C, adding antioxidant octylbutyldiphenylamine, Stir a...

Embodiment 2

[0034] The formula components and percentages of compound calcium sulfonate grease: 24% high base value synthetic calcium sulfonate, 8% high base value calcium salicylate, conversion agent (acetic acid, isopropanol, water mass ratio of 1 :2:4) 3%, calcium hydroxide 2%, compounding agent (mass ratio of boric acid and lauryl hydroxystearic acid is 1:2) 8%, octylbutyl diphenylamine 0.75%, 54.25% base oil.

[0035] Put the mixture of high base value synthetic calcium sulfonate, high base value calcium salicylate, part of the base oil (40% of the total base oil) and conversion agent into the reaction kettle, stir and heat to 85 ° C, keep the temperature for 60 minutes, and complete Calcium carbonate crystal form conversion, heating up to 90°C, adding calcium hydroxide and compounding agent for compounding, saponification and constant temperature reaction for 80 minutes; after saponification, heating up to 180°C, lowering to 90°C, adding antioxidant octylbutyldiphenylamine, Stir and...

Embodiment 3

[0037] The formula components and percentages of compound calcium sulfonate grease: 36% high base value synthetic calcium sulfonate, 9% high base value calcium salicylate, conversion agent (acetic acid, isopropanol, water mass ratio of 1 :2:4) 3.5%, calcium hydroxide 1.5%, compounding agent (mass ratio of boric acid and lauryl hydroxystearic acid is 1:2) 6%, octylbutyl diphenylamine 0.5%, 43.5% base oil.

[0038] Put the mixture of high base value synthetic calcium sulfonate, high base value calcium salicylate, part of the base oil (45% of the total base oil) and conversion agent into the reaction kettle, stir and heat to 80 ° C, keep the temperature for 80 minutes, and complete Calcium carbonate crystal form transformation, heating up to 90°C, adding calcium hydroxide and compounding agent for compounding, saponification and constant temperature reaction for 90 minutes; after saponification, heating up to 200°C, lowering to 100°C, adding antioxidant octylbutyl diphenylamine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com