Monitoring system for field leakage points of ferrous metallurgy gas pipes

A gas pipeline and monitoring system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as reducing emergency repair efficiency, prolonging judgment time, delaying emergency repair time, etc., and achieving significant safety and social benefits. , improve speed and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

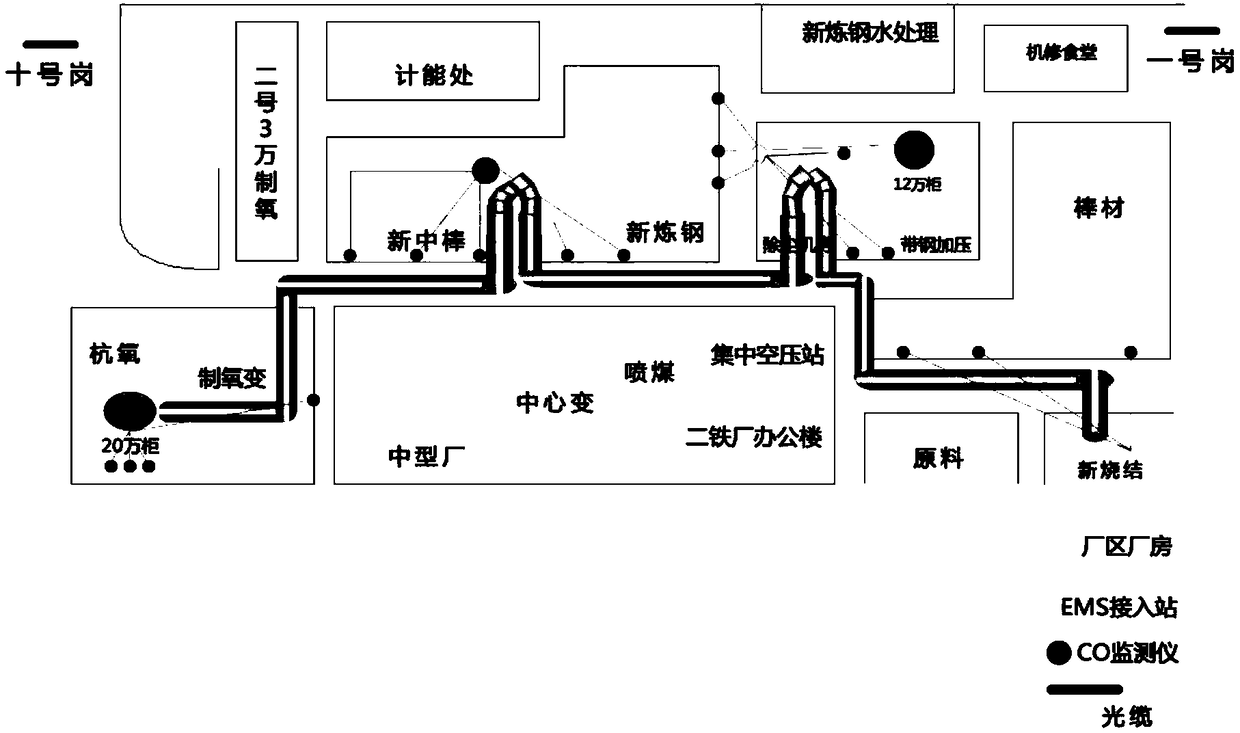

[0016] This embodiment takes the monitoring of the gas leakage of the water-sealed tank of the gas main pipe of Iron and Steel Avenue of an iron and steel group as an example (such as figure 1 ), the CO detection signal is collected at the collection station near the water-sealed tank of the gas pipeline, and the leakage of the water-sealed gas is monitored in real time on the host computer, and an alarm is issued if it is found to be excessive.

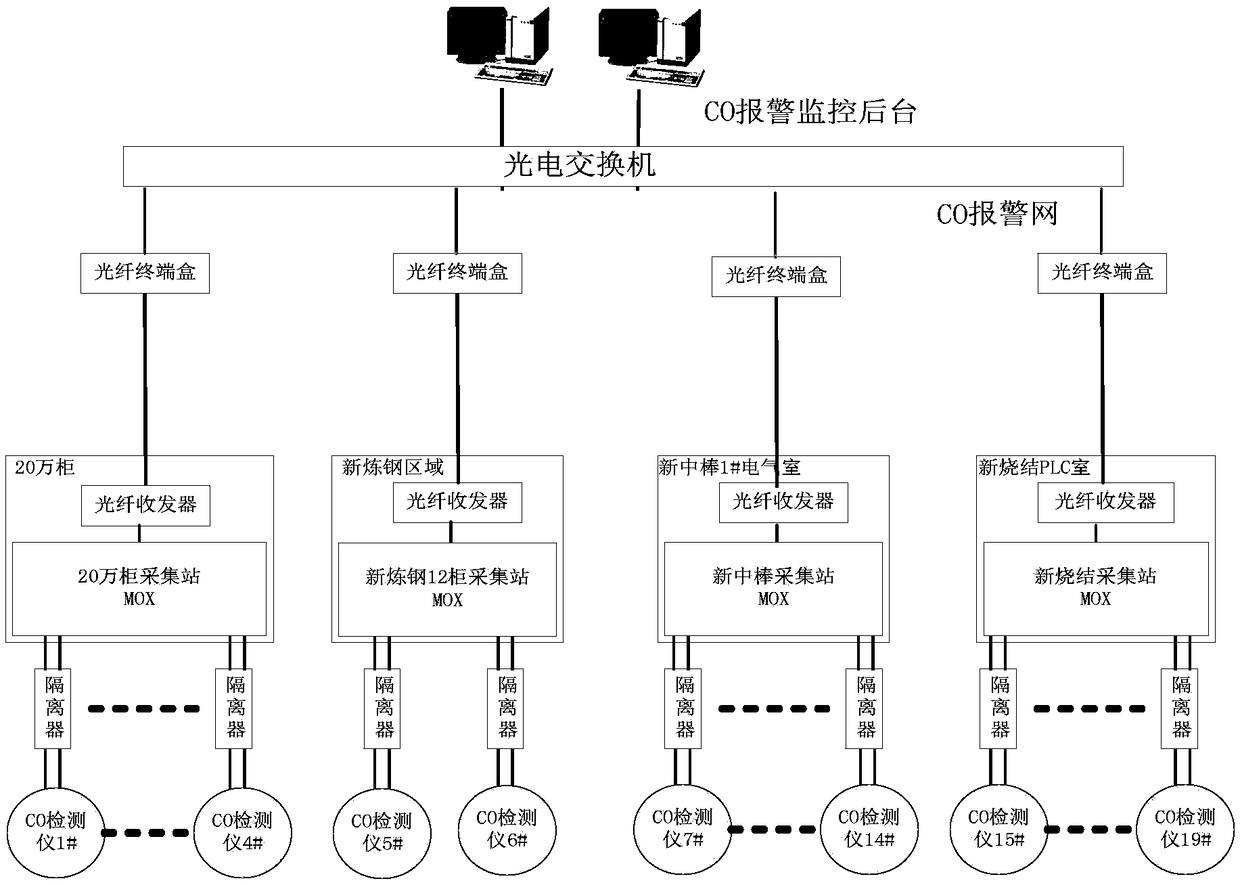

[0017] like figure 2 , The detection system takes several three-wire flameproof fixed CO detectors as the core, collects the CO concentration at the on-site monitoring point, and adopts wired signal collection and transmission. The CO detector is connected to the collection station through the RS485 interface (as shown in the 200,000 cabinet station, the new steelmaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com