A kind of nano-carbon composite ternary material and preparation method thereof

A ternary material and nano-carbon technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reducing surface area and utilization rate, affecting the structural stability and cycle of lithium-ion battery cathode materials Stability and high rate performance, nano-carbons are prone to agglomeration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A nano-carbon composite ternary material and a preparation method thereof. The preparation method described in this embodiment is:

[0027] 1) According to the solution concentration of 4 ~ 5kg / m 3 , adding nano-carbon into deionized water and stirring for 1-2 hours to obtain solution I.

[0028] 2) According to the nano-carbon: LiNi 1-x-y co x mn y o 2 The mass ratio of the ternary material is 1: (3~8), and the LiNi is added to the solution I 1-x-y co x mn y o 2 The ternary material was stirred for 0.5-1 hour to obtain solution II.

[0029] 3) The solution II is added dropwise into the liquid nitrogen solution to obtain spherical beads, and then freeze-dried in a vacuum freeze dryer for 48-72 hours to obtain a nano-carbon composite ternary material.

[0030] The nano-carbon is reduced graphene.

[0031] The LiNi 1-x-y co x mn y o 2 The ternary material is LiNi 0.6 co 0.2 mn 0.2 o2 .

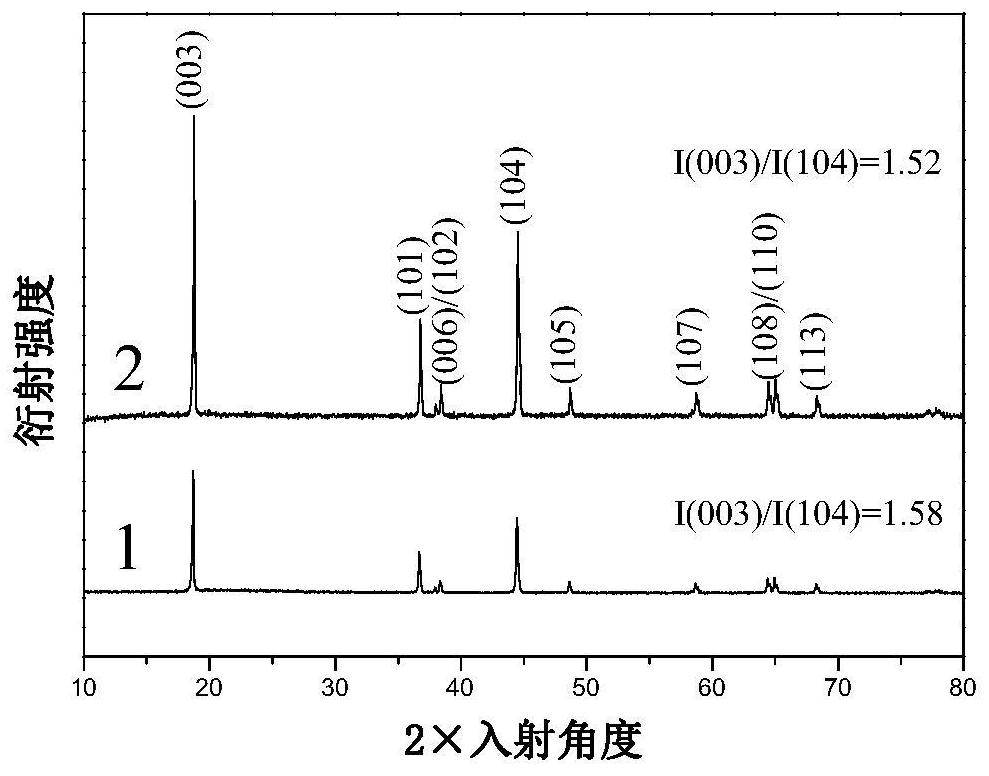

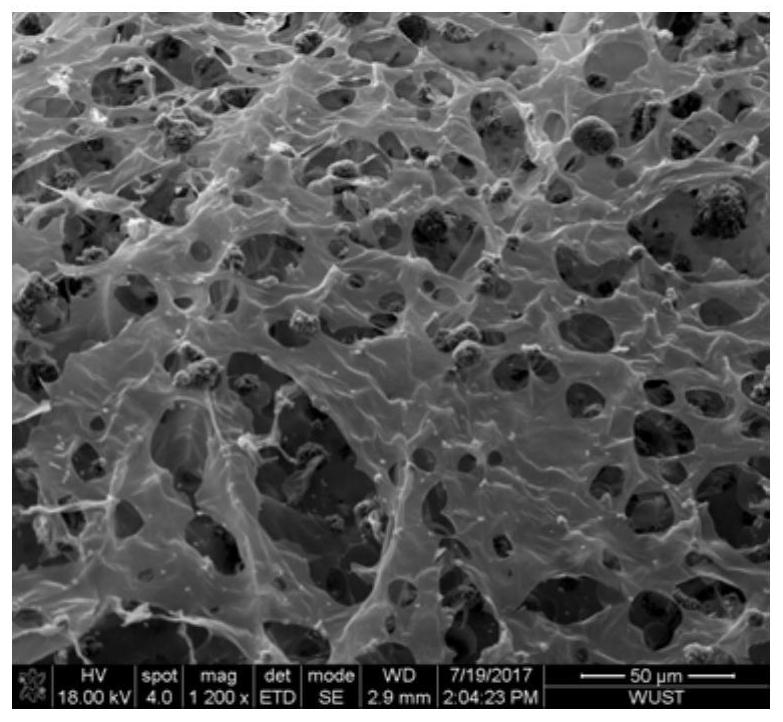

[0032] figure 1 It is a kind of nano-carbon composite ternary mat...

Embodiment 2

[0037] A nano-carbon composite ternary material and a preparation method thereof. The preparation method described in this embodiment is:

[0038] 1) According to the solution concentration of 3.5 ~ 4.5kg / m 3 , adding nano-carbon into deionized water and stirring for 1-2 hours to obtain solution I.

[0039] 2) According to the nano-carbon: LiNi 1-x-y co x mn y o 2 The mass ratio of the ternary material is 1:(6~11), and the LiNi is added to the solution I 1-x-y co x mn y o 2 The ternary material was stirred for 0.5-1 hour to obtain solution II.

[0040] 3) The solution II is added dropwise into the liquid nitrogen solution to obtain spherical beads, and then freeze-dried in a vacuum freeze dryer for 48-72 hours to obtain a nano-carbon composite ternary material.

[0041] The nano-carbon is doped graphene.

[0042] The LiNi 1-x-y co x mn y o 2 The ternary material is LiNi 0.8 co 0.1 mn 0.1 o 2 .

[0043] The nano-carbon composite ternary material prepared in ...

Embodiment 3

[0045] A nano-carbon composite ternary material and a preparation method thereof. The preparation method described in this embodiment is:

[0046] 1) According to the solution concentration of 3 ~ 4kg / m 3 , adding nano-carbon into deionized water and stirring for 1-2 hours to obtain solution I.

[0047] 2) According to the nano-carbon: LiNi 1-x-y co x mn y o 2 The mass ratio of the ternary material is 1:(9~14), and the LiNi is added to the solution I 1-x-y co x mn y o 2 The ternary material was stirred for 0.5-1 hour to obtain solution II.

[0048] 3) The solution II is added dropwise into the liquid nitrogen solution to obtain spherical beads, and then freeze-dried in a vacuum freeze dryer for 48-72 hours to obtain a nano-carbon composite ternary material.

[0049] The nano carbon is doped carbon nano tube.

[0050] The LiNi 1-x-y co x mn y o 2 The ternary material is LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0051] The nano-carbon composite ternary material prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com