Smearing type reprocessed cheese and preparation method thereof

A processed cheese and spread-type technology, which is applied in the field of spread-type processed cheese and its preparation, can solve the problems such as the limited number of spread-type processed cheese varieties, and achieves excellent spreadability, high nutritional value and rich milk flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a second aspect, the present invention also provides a method for preparing the spread-type processed cheese, the method comprising the following steps:

[0027] (1) Natural cheese, butter, skimmed milk powder, whey protein powder, polydextrose, white sugar, water, emulsified salt, xanthan gum, mono- and diglyceride fatty acid esters, sodium alginate, modified starch, salt and After the citric acid is mixed, the mixture is obtained;

[0028] (2) Sterilize, homogenize and keep warm after heating and stirring the mixture;

[0029] (3) Filling and cooling down.

[0030] Further, in step (2), heat and stir at a rotation speed of 900-1500 rpm for 1-2 min. The heating temperature takes the sterilization temperature as the upper limit. Under the selected conditions, the ingredients can be mixed quickly and fully evenly.

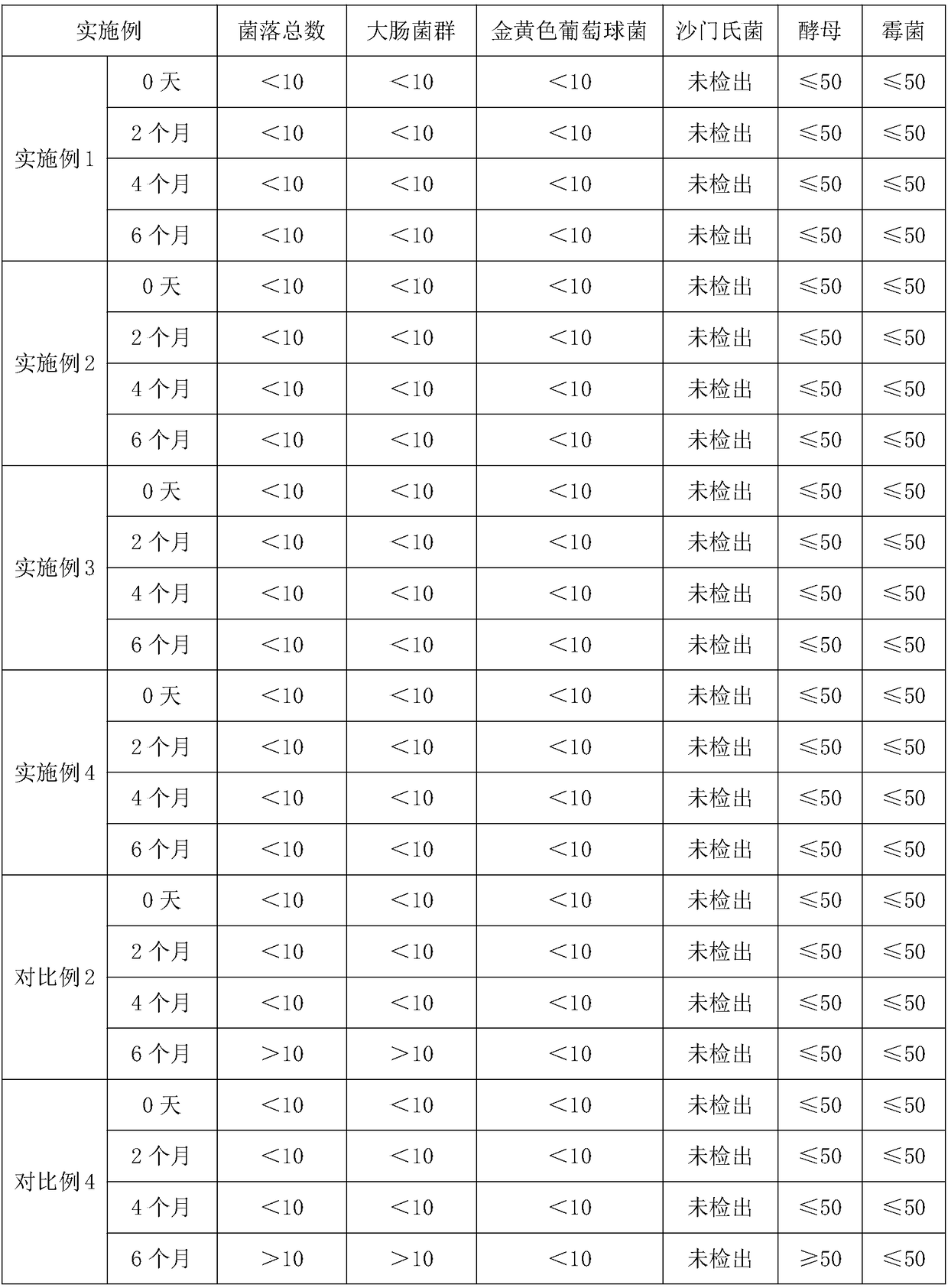

[0031] Further, in step (2), the sterilization temperature is 95-99° C. and the time is 2-5 minutes. Under the sterilization conditions, all the misce...

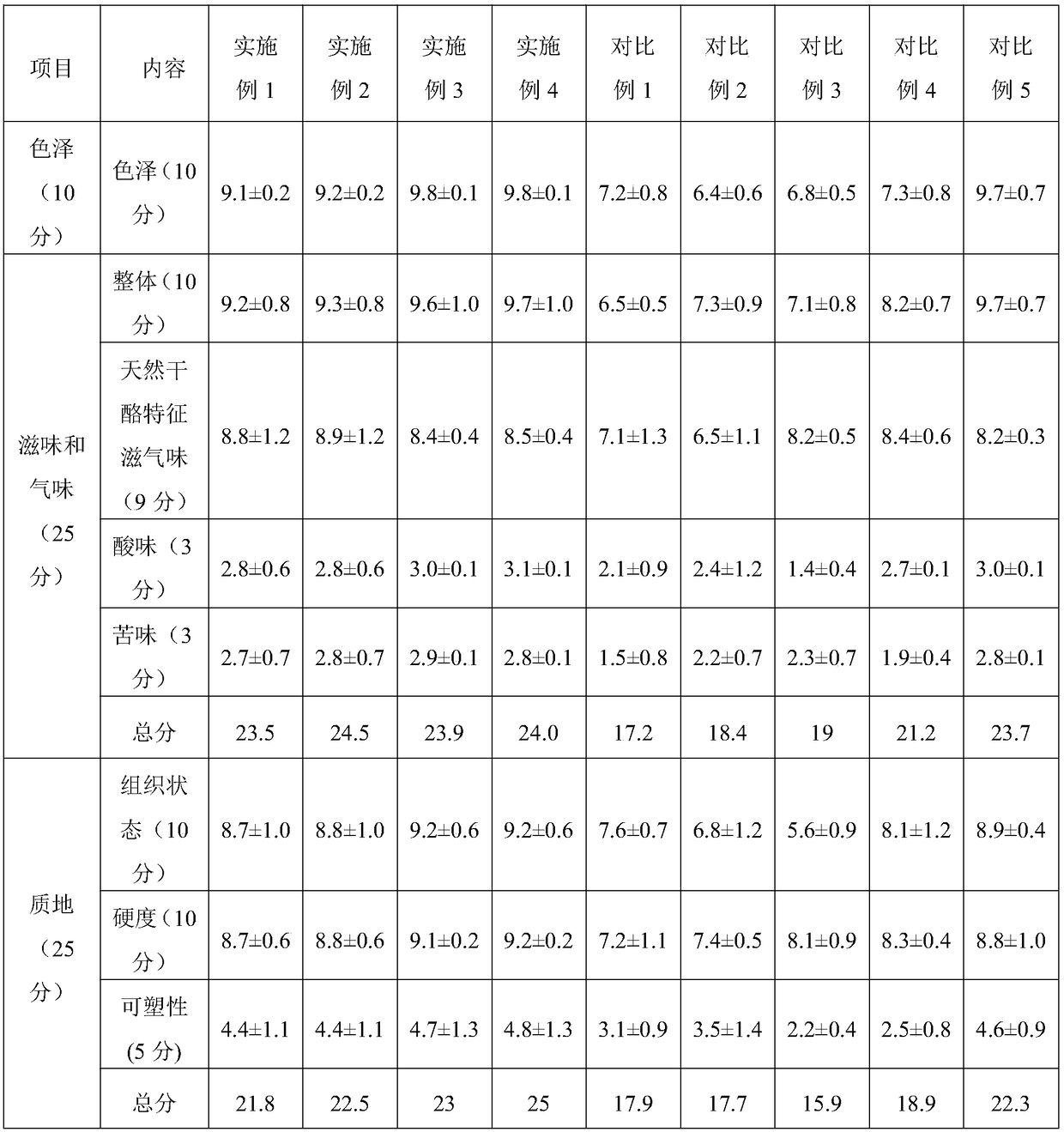

Embodiment 1

[0037] A spreadable processed cheese is prepared from the following raw materials: 18% natural cheese, 14.6% butter, 13.7% skimmed milk powder, 0.8% whey protein powder, 1.0% polydextrose, 1.0% white sugar, emulsified salt 7‰, xanthan gum 0.1%, mono- and diglyceride fatty acid esters 0.2%, sodium alginate 0.2%, modified starch 0.1%, salt 0.4%, citric acid 0.1%, and the balance is water. The emulsifying salt is composed of sodium hexametaphosphate and trisodium phosphate with a mass ratio of 1:1. The modified starch is sodium starch octenyl succinate.

[0038] The specific steps of the processed cheese preparation method are as follows: mixing materials → heating and stirring → sterilization → homogenization → heat preservation → filling → cooling.

[0039] (1) Mixing: mix natural cheese, butter, skimmed milk powder, whey protein powder, polydextrose and white sugar raw materials in a melting pot, add appropriate amount of water, add emulsified salt, xanthan gum, mono- and dig...

Embodiment 2

[0048] A spreadable processed cheese is prepared from the following raw materials in mass content: 30% natural cheese, 19.6% butter, 5.9% skimmed milk powder, 1.4% whey protein powder, 1.4% polydextrose, 1.4% white sugar, emulsified salt 12‰, xanthan gum 0.2%, mono- and diglyceride fatty acid ester 0.3%, sodium alginate 0.3%, modified starch 0.3%, salt 0.6%, citric acid 0.3%, the balance is water. The emulsifying salt is composed of sodium hexametaphosphate and trisodium phosphate with a mass ratio of 3:1. The modified starch is sodium starch octenyl succinate.

[0049] The specific steps of the processed cheese preparation method are as follows: mixing materials → heating and stirring → sterilization → homogenization → heat preservation → filling → cooling.

[0050](1) Mixing: mix natural cheese, butter, skimmed milk powder, whey protein powder, polydextrose and white sugar raw materials in a melting pot, add appropriate amount of water, add emulsified salt, xanthan gum, mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com