Preparation method of capsules with high water retention

A water-retaining type and capsule technology, which is applied in capsule delivery, medical preparations of non-active ingredients, pharmaceutical formulas, etc., can solve the problems of poor film-forming and water-retaining properties, achieve good film-forming properties, improve water-retaining properties, and water-retaining performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

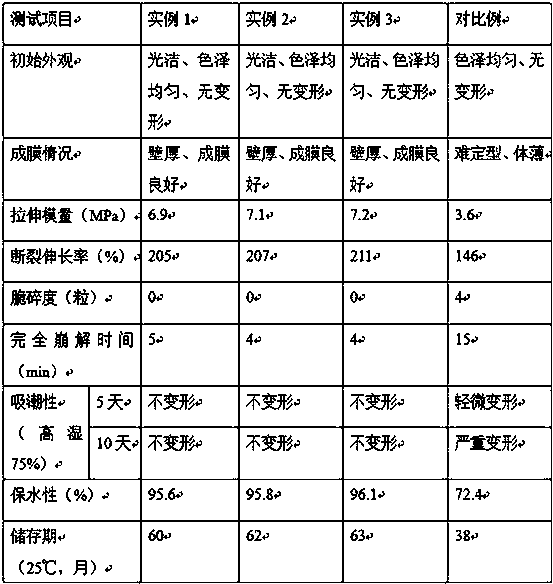

Examples

example 1

[0023] Take the water moss and put it into the steam explosion tank, and feed steam preheated to 220°C into the steam explosion tank until the pressure in the steam explosion tank reaches 2.2MPa. After keeping the pressure for 30s, open the discharge valve of the steam explosion tank to make the steam The material in the explosion tank is sprayed into the receiving tank instantaneously, and the material in the receiving tank is collected to obtain sphagnum fiber; the mass fraction is 40% chloroacetic acid solution and isopropanol are mixed evenly at a mass ratio of 3:4 to obtain a mixed solution, and the The above-mentioned sphagnum fiber, the mixed solution and the sodium hydroxide solution with a mass fraction of 20% are mixed according to a mass ratio of 2: 1: 1 and then packed into a three-necked flask, and nitrogen is introduced into the three-necked flask until all the air is replaced. Under nitrogen protection, heat up to 30°C and stir for 30 minutes to obtain a reactant...

example 2

[0025] Take sphagnum moss and put it into the steam explosion tank, and pass steam preheated to 230°C into the steam explosion tank until the pressure in the steam explosion tank reaches 2.3MPa. After maintaining the pressure for 35s, open the steam explosion tank discharge valve to make the The material in the explosion tank is sprayed into the receiving tank instantaneously, and the material in the receiving tank is collected to obtain sphagnum fiber; the mass fraction is 40% chloroacetic acid solution and isopropanol are mixed evenly at a mass ratio of 3:4 to obtain a mixed solution, and the The above-mentioned sphagnum fiber, the mixed solution and the sodium hydroxide solution with a mass fraction of 20% are mixed according to a mass ratio of 2: 1: 1 and then packed into a three-necked flask, and nitrogen is introduced into the three-necked flask until all the air is replaced. Under nitrogen protection, heat up to 35°C and stir for 35 minutes to obtain a reactant containin...

example 3

[0027]Take the water moss and put it into the steam explosion tank, and pass steam preheated to 240°C into the steam explosion tank until the pressure in the steam explosion tank reaches 2.4MPa. After keeping the pressure for 40s, open the discharge valve of the steam explosion tank to make the steam explosion tank The material in the explosion tank is sprayed into the receiving tank instantaneously, and the material in the receiving tank is collected to obtain sphagnum fiber; the mass fraction is 40% chloroacetic acid solution and isopropanol are mixed evenly at a mass ratio of 3:4 to obtain a mixed solution, and the The above-mentioned sphagnum fiber, the mixed solution and the sodium hydroxide solution with a mass fraction of 20% are mixed according to a mass ratio of 2: 1: 1 and then packed into a three-necked flask, and nitrogen is introduced into the three-necked flask until all the air is replaced. Under nitrogen protection, heat up to 40°C and stir for 40 minutes to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com