Preparation method of Ag-Si nanometer welding paste for improving silver electrochemistry migration

A silver electrochemistry and nano-welding technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of changing dielectric properties, affecting reliability, equipment failure, etc., and achieving simple preparation process, good stability and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (a) Mix silicon particles with an average particle size of 15-100 nm and diluent terpineol for 30 minutes with the assistance of an ultrasonic water bath, wherein the quality of the silicon particles is 0.1 g, and the quality of terpineol is 0.1 g;

[0026] (b) Add the mixture of silicon particles and diluent terpineol prepared above to the nano-silver solder paste with an average particle size of 50-500nm, wherein the quality of the silver solder paste is 113.52g to obtain silver, silicon particles and pine A mixture of oleyl alcohols;

[0027] (c) The mixture of silver, silicon particles and terpineol obtained in step (b) was stirred for 60s by a high-efficiency stirrer with a rotation speed of 2000r / min to prepare Ag-Si nano-solder paste.

Embodiment 2

[0029] (a) Mix silicon particles with an average particle size of 15-100 nm and diluent terpineol for 15 minutes with the assistance of an ultrasonic water bath, wherein the quality of the silicon particles is 1 g, and the quality of terpineol is 2 g;

[0030] (b) Add the mixture of silicon particles and diluent terpineol prepared above to the nano-silver solder paste with an average particle size of 50-500nm, wherein the quality of the silver solder paste is 112.5g, to obtain silver, silicon particles and terpineol A mixture of oleyl alcohols;

[0031] (c) The mixture of silver, silicon particles and terpineol obtained in step (b) was stirred for 45s by a high-efficiency stirrer with a rotation speed of 1500r / min to prepare Ag-Si nano-solder paste.

Embodiment 3

[0033] (a) Mix silicon particles with an average particle size of 15-100 nm and diluent terpineol for 45 minutes with the assistance of an ultrasonic water bath, wherein the quality of the silicon particles is 15 g, and the quality of terpineol is 22.5 g;

[0034] (b) Add the mixture of silicon particles and diluent terpineol prepared above to the nano-silver solder paste with an average particle size of 50-500nm, wherein the mass of silver is 96.59g to obtain silver, silicon particles and terpineol mixture;

[0035] (c) The mixture of silver, silicon particles and terpineol obtained in step (b) was stirred for 30s by a high-efficiency stirrer with a rotation speed of 1000r / min to prepare Ag-Si nano-solder paste.

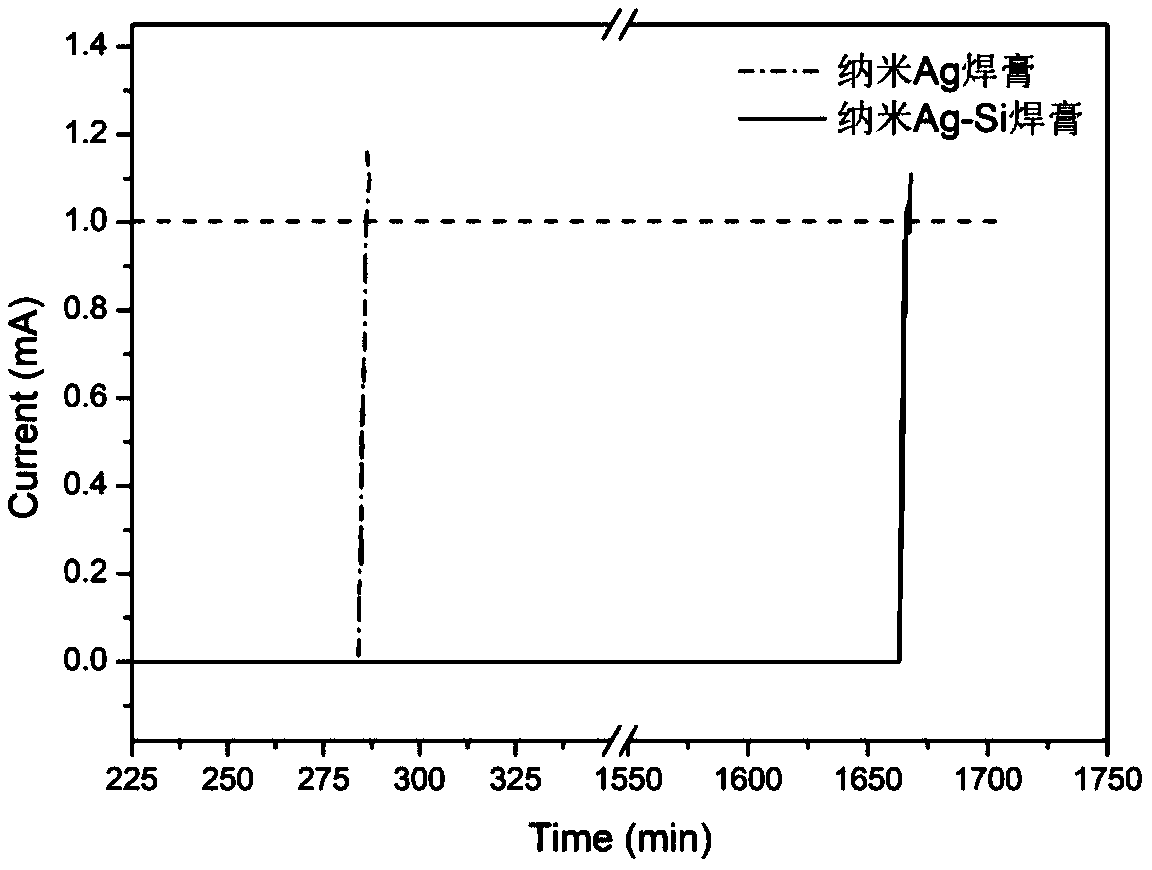

[0036] The prepared Ag-Si nano-solder paste and the commercially obtained nano-silver paste were sintered at a heating rate of 5 °C / min at 280 °C, kept for 30 min and cooled in the furnace, and then applied at a high temperature of 400 °C. Electromigration experime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com