A kind of preparation method of Ag-Si nano-solder paste that improves silver electrochemical migration

A silver electrochemical and nano-welding technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as changing dielectric properties, affecting reliability, and equipment failure, and achieves simple preparation process, good stability, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025](a) mixed with silicon particles having an average particle size of 15 to 100 nm and the diluent pine alcohol at a heroic water bath for 30 min, of which the mass of silicon particles was 0.1 g, and the mass of pine alcohol was 0.1 g.

[0026](b) The mixture of silicon particles and diluent pine alcohols prepared above was added to nano silver solder paste having average particle size of 50 to 500 nm, with silver solder paste to obtain silver, silicon particles and pine Mixture of oil alcohol;

[0027](c) The mixture of silver, silicon particles and phenolorol obtained by step (b) was stirred by a high-efficiency agitator gauge of 2000 r / min by a high-efficiency agitation instrument having a rotational speed of 2000 r / min.

Embodiment 2

[0029](a) mixed with silicon particles having a average particle size of 15 to 100 nm and the diluent pine alcohol at a proposition of the ultrasonic water bath, wherein the mass of silicon particles is 1 g, the mass of pine alcohol is 2g;

[0030](b) The mixture of the above-prepared silicon particles and diluent pine alcohol added to nano silver solder paste having a average particle size of 50 to 500 nm, wherein the mass of silver solder paste is 112.5 g, resulting in silver, silicon particles and pine. Mixture of oil alcohol;

[0031](c) The mixture of silver, silicon particles, and pine alcohol obtained by step (b) was stirred with a high-efficiency agitatorometer having a rotation speed of 1500 r / min, and the Ag-Si Nano-Si is obtained.

Embodiment 3

[0033](a) a mixture of silicon particles having an average particle size of 15 to 100 nm and the diluent pine alcohol were mixed with a concentrated water bath, of which the mass of silicon particles was 15 g, and the mass of pine alcohol was 22.5 g.

[0034](b) The mixture of silicon particles and diluent pine alcohols prepared above was added to nano-silver solder paste having a average particle size of 50 to 500 nm, with silver mass of 96.59 g, resulting in silver, silicon particles, and pine alcohol. mixture;

[0035](c) The mixture of silver, silicon particles and phenolorol obtained by step (b) was stirred by a high-efficiency agitation instrument having a rotational speed of 1000 r / min, and was prepared by agharged the Ag-Si Nano-Si.

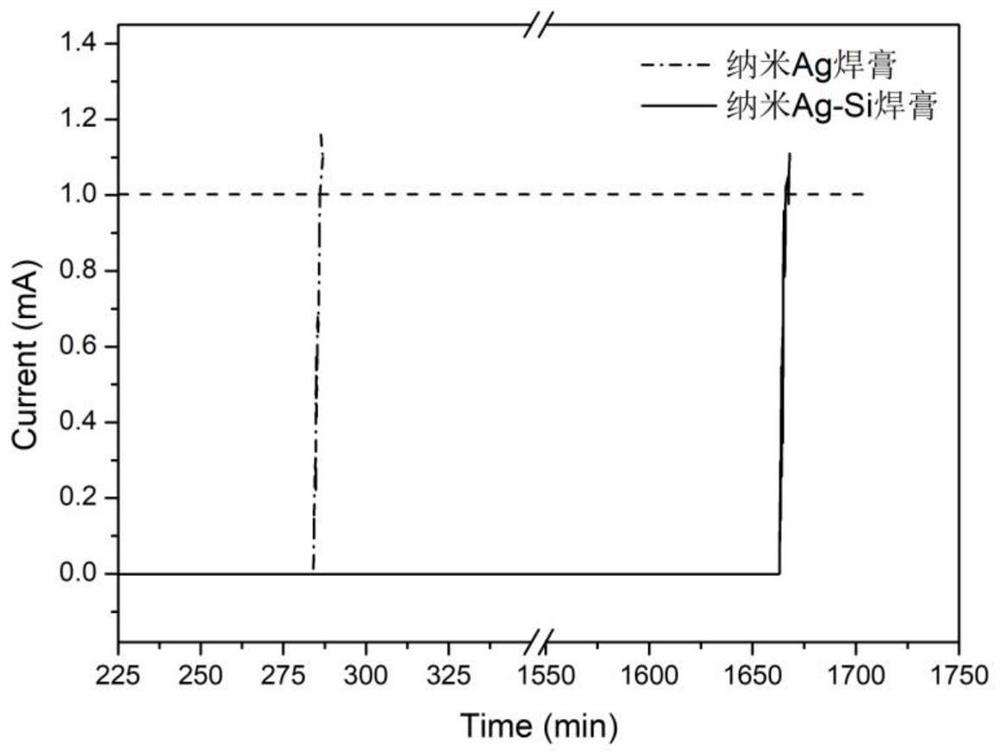

[0036]The obtained Ag-Si nano-Si nanor solder paste and the commercial nano silver solder paste were sintered at 280 ° C at a heating rate of 5 ° C / min, and the rear furnace was cold, then at a high temperature condition of 400 ° C, applied The 200V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com