Method for preparing PMMA with high molecular weight and narrow molecular weight distribution

A technology with narrow molecular weight distribution and high molecular weight, applied in the field of polymethyl methacrylate, can solve the problems of long reaction time, high energy consumption, expensive RAFT reagent, etc., and achieve the effects of high utilization rate, mild conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

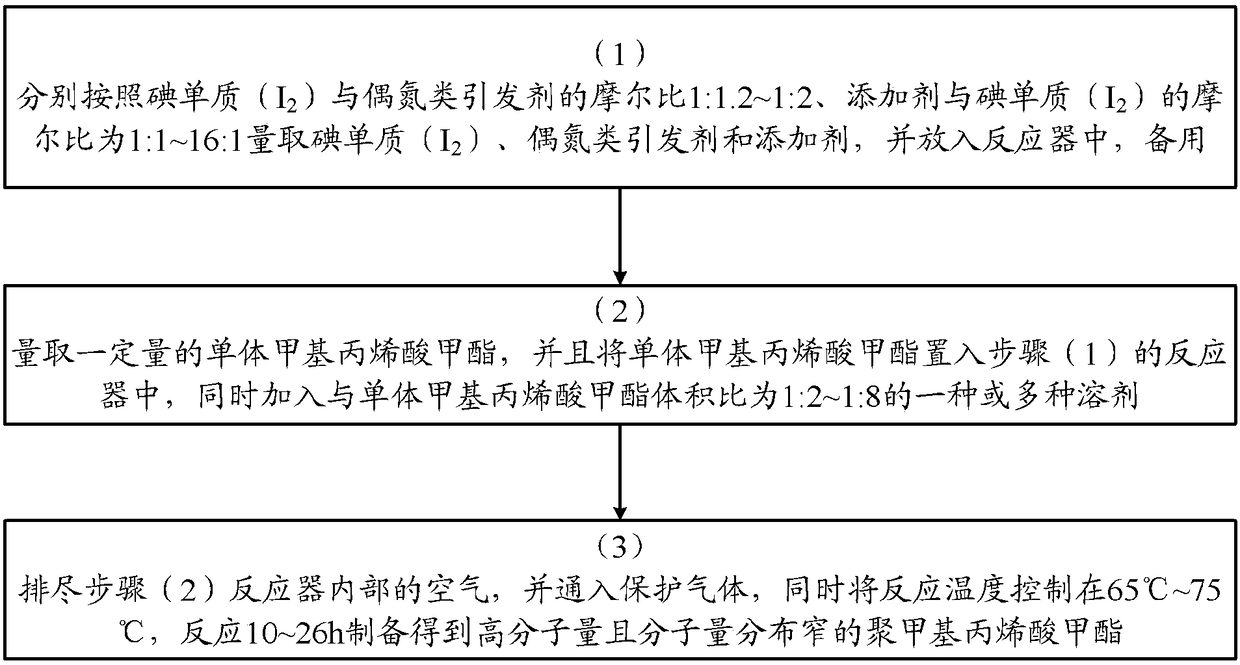

Method used

Image

Examples

Embodiment 1

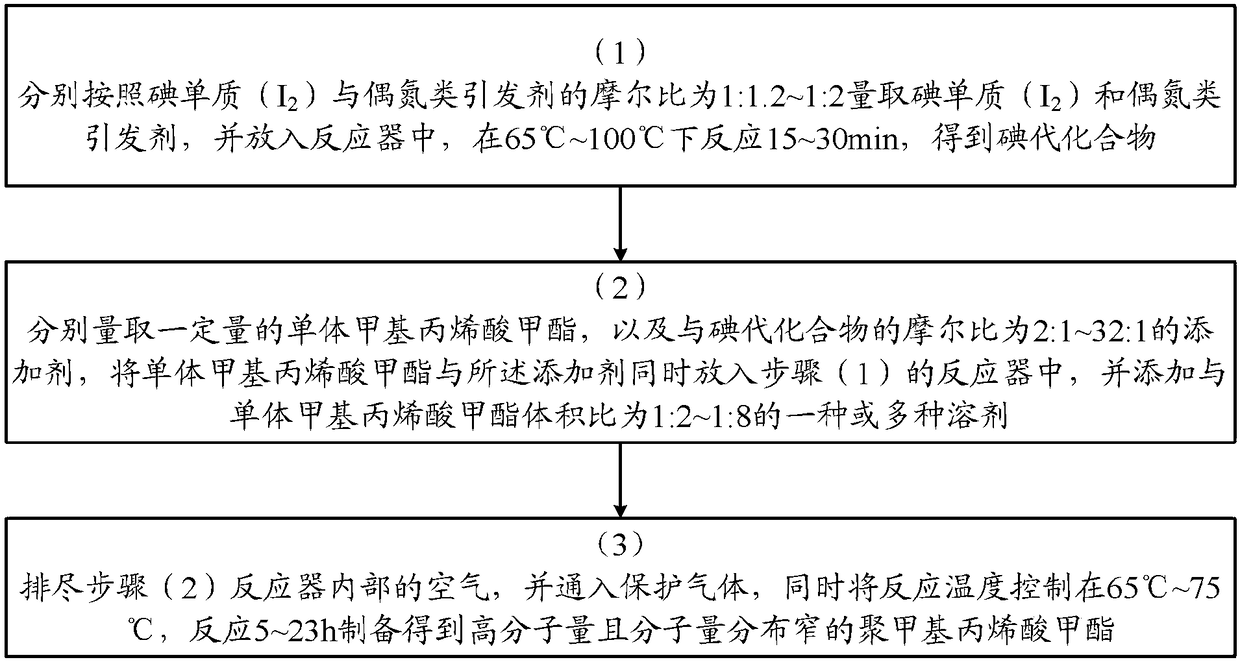

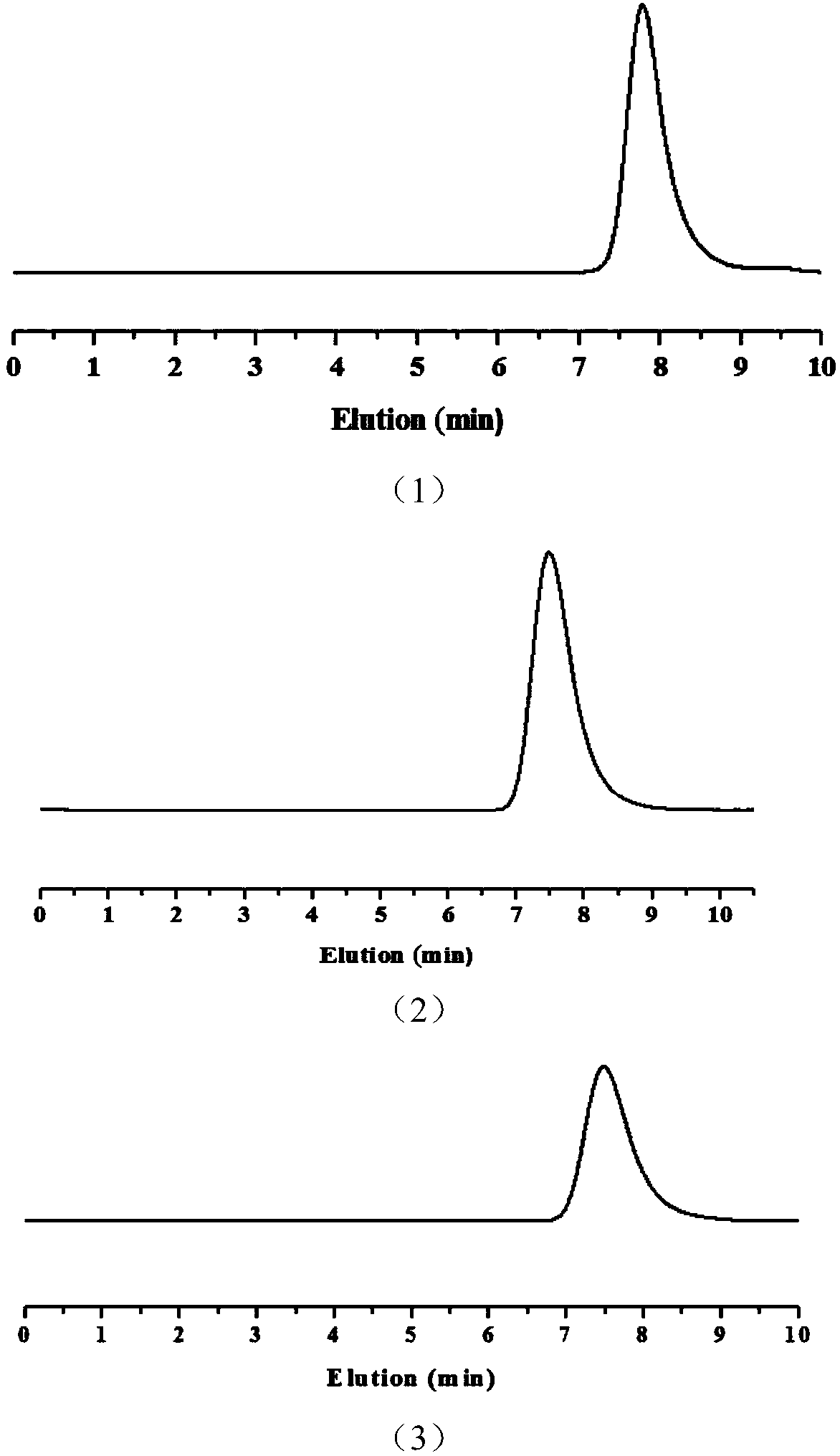

[0064] Add 0.1900g of iodine, 0.1850g of azobisisobutyronitrile, 50g of methyl methacrylate, and 0.8598g of hexamethylphosphoric triamide into a 50ml single-necked flask with magnetic stirring to form a uniform solution. The air in it was "pumped-dissolved" four times. Under the condition of avoiding light, the temperature was raised to 70°C in an oil bath. After 16 hours of reaction, it was slowly cooled to room temperature and discharged to obtain a number average molecular weight of 30500 and a dispersion coefficient. 1.26 polymethyl methacrylate. The GPC curve of the polymer is as image 3 (1) shown.

Embodiment 2

[0066] Add 0.1900g of iodine, 0.1850g of azobisisobutyronitrile, 60g of methyl methacrylate, and 1.1464g of hexamethylphosphoric triamide into a 100ml single-necked flask with magnetic stirring to form a homogeneous solution. The air in it was "pumped-dissolved" four times. Under the condition of avoiding light, the temperature was raised to 75°C in an oil bath, and after 18 hours of reaction, it was slowly cooled to room temperature and discharged, and the number average molecular weight was 50800, and the dispersion coefficient was 1.28. of polymethyl methacrylate. The GPC curve of the polymer is as image 3 (2) shown.

Embodiment 3

[0068] Add 0.1900g of iodine, 0.1850g of azobisisobutyronitrile, 90g of methyl methacrylate, and 1.7196g of hexamethylphosphoric triamide into a 100ml single-necked flask with magnetic stirring to form a homogeneous solution. The air in it was "pumped-dissolved" four times. Under the condition of avoiding light, the temperature was raised to 75°C in an oil bath. After 20 hours of reaction, it was slowly cooled to room temperature and then discharged. The number average molecular weight was 60700, and the dispersion coefficient was 1.31. of polymethyl methacrylate. The GPC curve of the polymer is as image 3 (3) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com