Polylactic acid foamed material having nano foam pores and preparation method thereof

A foam material, polylactic acid technology, applied in the field of polylactic acid foam material, can solve the problems of increased cell size, cell merging, unfavorable PLA nanofoam preparation, etc. Effect of Foam Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The polylactic acid foam material with nano-cells of embodiment 1, comprises the component of following quality:

[0059] Polylactic acid resin 59.937g;

[0060] Epoxy chain extender 0.06g;

[0061] Hydroxy-functionalized graphene (HG) 0.003g.

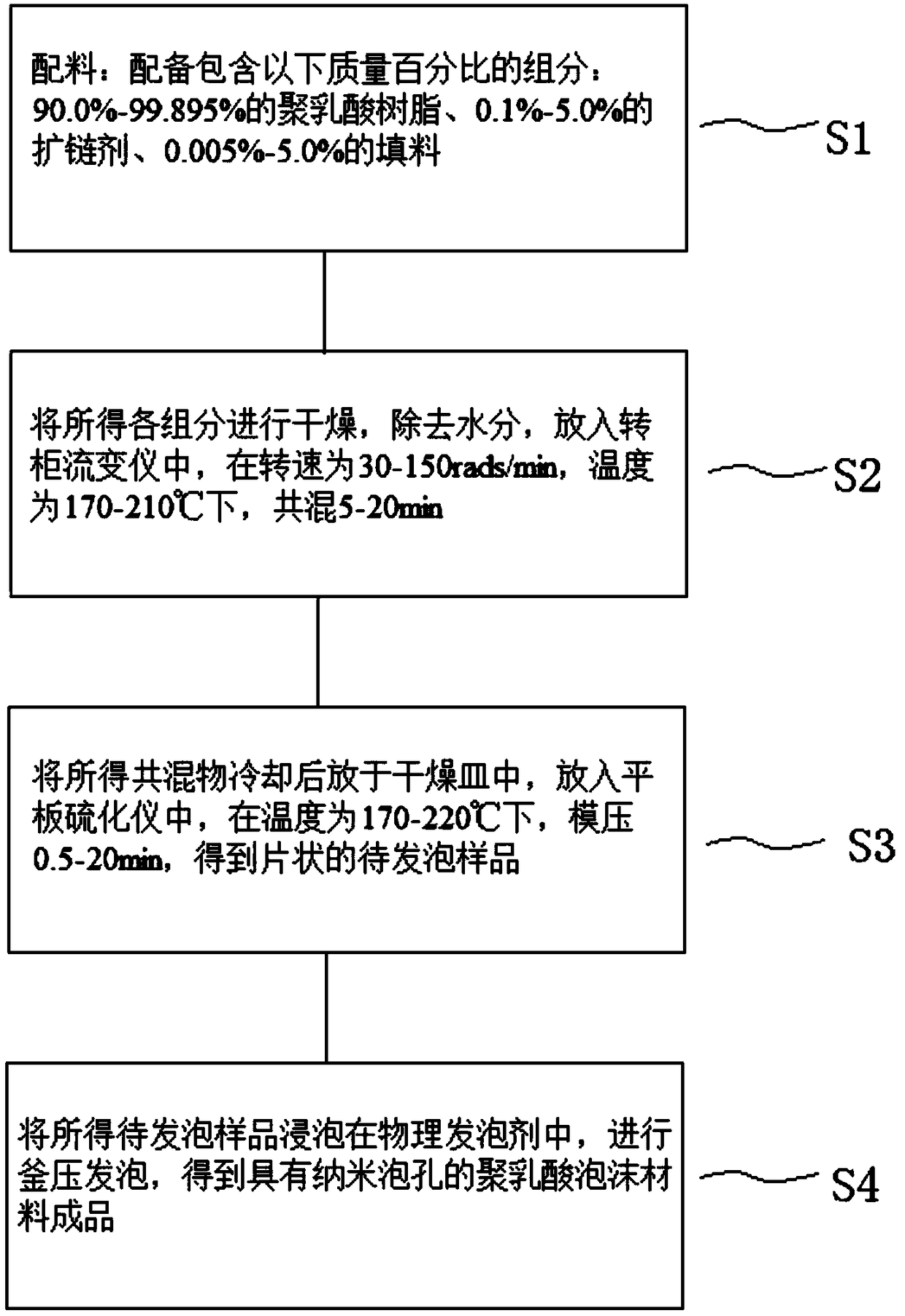

[0062] like figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 1 is as follows:

[0063] S1: Ingredients: equipped with the following components: 59.937g polylactic acid resin, 0.06g epoxy-based chain extender, 0.003g hydroxyl-functionalized graphene (HG);

[0064] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 190 ° C, the rotation speed is 60 rads / min, and after blending for 15 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0065] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 190°C...

Embodiment 2

[0068] The polylactic acid foam material with nano-cells of embodiment 2, comprises the component of following quality:

[0069] Polylactic acid resin 57g;

[0070] Anhydride chain extender 1.5g;

[0071] Hydroxy-functionalized graphene (HG) 1.5g.

[0072] like figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 2 is as follows:

[0073] S1: Ingredients: equipped with the following components: 57g polylactic acid resin, 1.5g anhydride chain extender, 1.5g hydroxyl-functionalized graphene (HG);

[0074] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 190 ° C, the rotation speed is 60 rads / min, and after blending for 15 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0075] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 190°C for 20 minu...

Embodiment 3

[0078] The polylactic acid foam material with nano-cells of embodiment 3, comprises the component of following quality:

[0079] Polylactic acid resin 54g;

[0080] Isocyanate chain extender 3g;

[0081] Cage polysilsesquioxane (POSS) 3g.

[0082] like figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 3 is as follows:

[0083] S1: Ingredients: equipped with the following components: 54g polylactic acid resin, 3g isocyanate chain extender, 3g cage polysilsesquioxane (POSS);

[0084] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 170 ° C, the rotation speed is 80 rads / min, and after blending for 10 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0085] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 200°C for 10 minutes to prepare a sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com