Linlanyuye liquor brewing process

A technology of Linlan Yuye liquor and technology, which is applied in the field of brewing technology of Linlan Yuye liquor, can solve the problems of wine quality to be improved, complex extraction process, loss of active ingredients, etc., achieve mellow and rich taste, adapt to a wide range of people, and improve resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

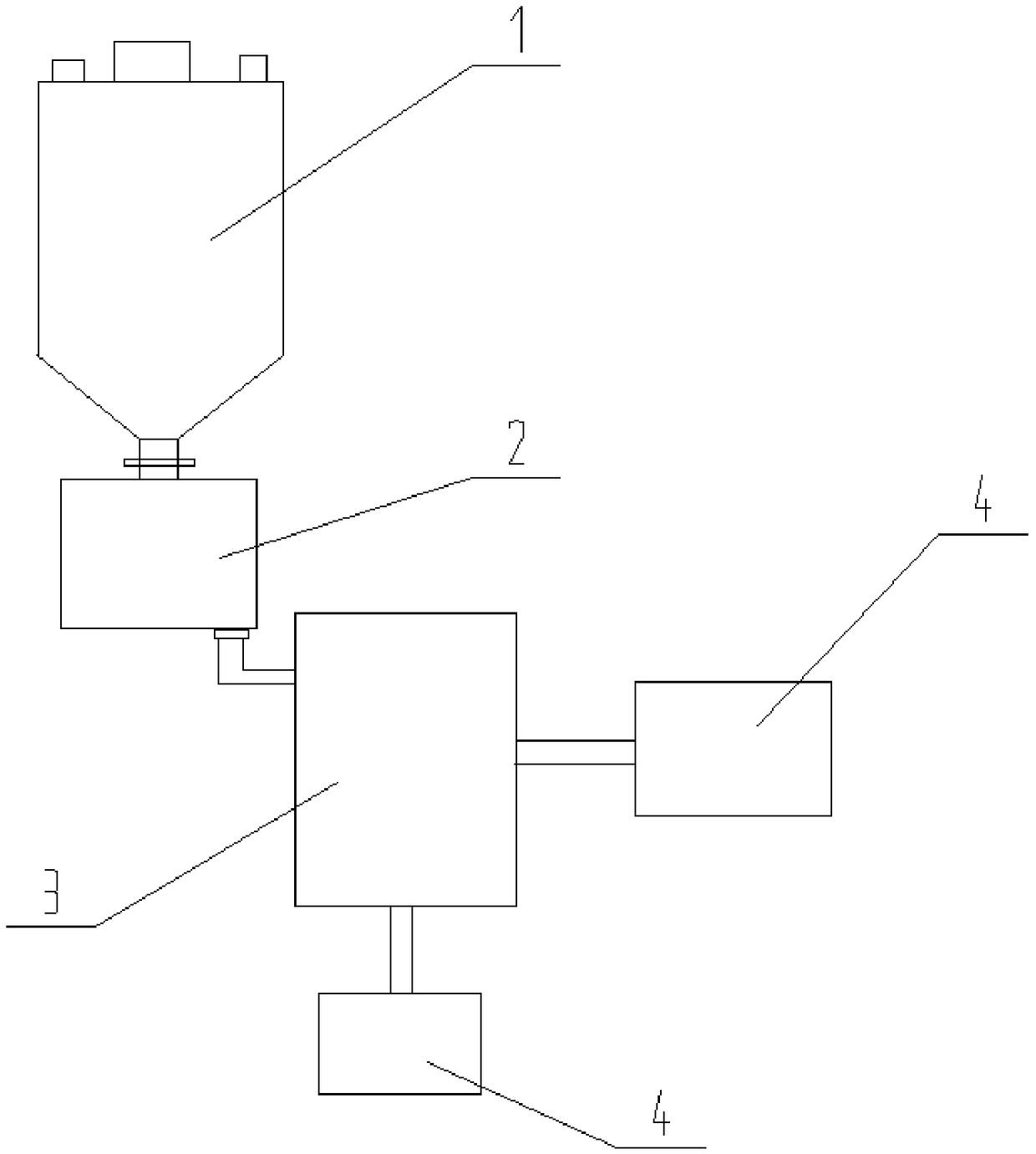

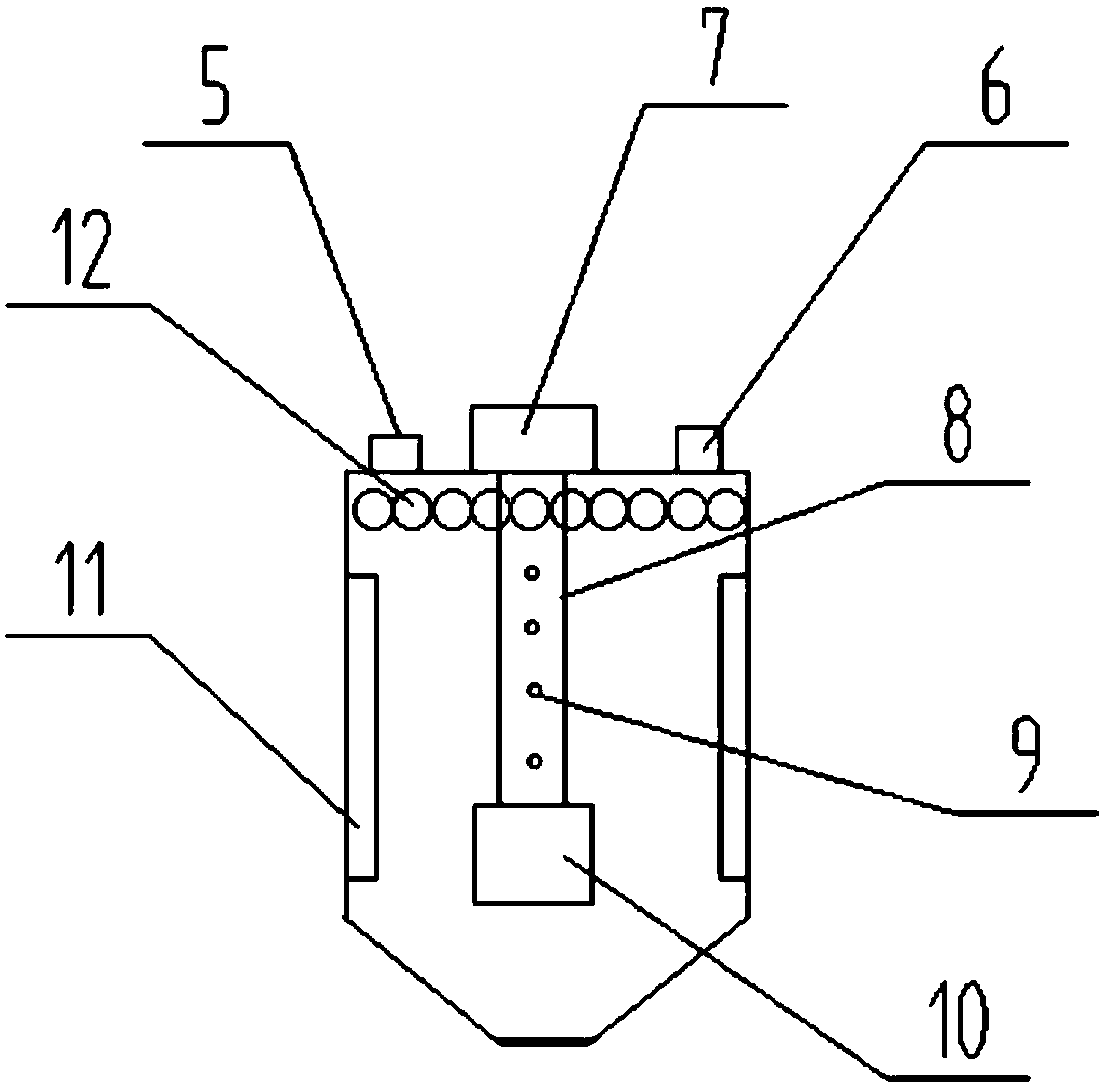

[0046] Such as Figure 2-3 As shown, the present embodiment provides an extraction device, which includes a reactor 1, a solid-liquid separation device 2, a filter device 3 and two collection devices 4, and the filter device 3 is located between the reactor 1 and the solid-liquid separation device 2 On the connecting pipe, the outer top of the reactor 1 is provided with a liquid inlet 5 and a feed inlet 6 connected to the inside of the reactor 1 at intervals. The lower end of the feed inlet is connected to a grinding device 12, and the grinding device 12 is composed of a plurality of adjacently arranged It consists of grinding balls; the outer top of the reaction kettle 1 is also provided with an enzyme spraying device 7, and the inner top of the reaction kettle 1 is provided with a connecting frame 8, and the connecting frame 8 is provided with a nozzle 9 connected to the enzyme spraying device 7, and the end of the connecting frame 8 An ultrasonic generator 10 is set, and th...

Embodiment 2

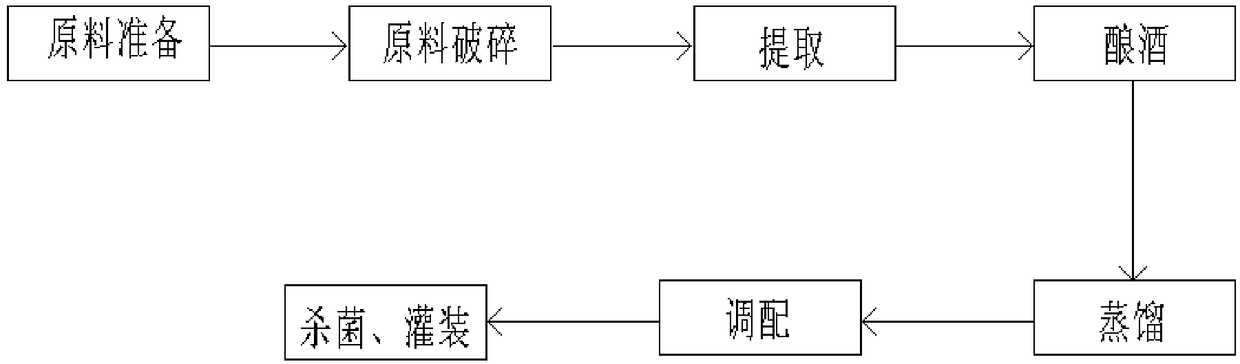

[0050] Such as Figure 1-3 As shown, the present invention provides a kind of brewing process of Linlan Yuye wine, comprising the following steps:

[0051] (1) Preparation of raw materials: take the following raw materials by weight for later use: 20 parts of Dendrobium candidum, 10 parts of Dendrobium candidum flower, 10 parts of Polygonatum odoratum, 8 parts of medlar, 8 parts of chrysanthemum, 6 parts of Niu Dali, 8 parts of orange peel, 800 parts of white wine Wherein, the degree of white wine in the raw material is 50 degrees, and this white wine is made by following method: a, preparation mixed coarse grain: waxy sorghum, barley, corn are mixed and broken to the ratio of 3:1:1 according to mass ratio 40 mesh standard sieves to obtain the mixed coarse grains for subsequent use; b, cooking: put the mixed coarse grains into the high-pressure cooking pot, add water in the pot, the amount of water added is 50% of the mixed coarse grains gross weight, cover the high-pressure c...

Embodiment 3

[0059] Such as Figure 1-3 As shown, the present invention provides a kind of brewing process of Linlan Yuye wine, comprising the following steps:

[0060] (1) Preparation of raw materials: take the following raw materials by weight for later use: 25 parts of Dendrobium candidum, 15 parts of Dendrobium candidum flower, 15 parts of Polygonatum odoratum, 10 parts of medlar, 10 parts of chrysanthemum, 12 parts of Niu Dali, 10 parts of tangerine peel, 1000 parts of white wine Wherein, the degree of white wine in the raw material is 55 degrees, and this white wine is made by following method: a, preparation mixed coarse grain: waxy sorghum, barley, corn are mixed and broken to the ratio of 3:2:1 according to mass ratio 40 mesh standard sieves to obtain the mixed coarse grains for subsequent use; b, cooking: put the mixed coarse grains into the high-pressure cooking pot, add water in the pot, the amount of water added is 60% of the mixed coarse grains gross weight, cover the high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com