mg-zn-cu-zr-(cr-ca) alloy under gpa level high pressure and its preparation method

A high-pressure, alloying technology, applied in the field of Mg-Zn-Cu alloys, can solve the problems of increasing the nucleation rate, reducing the nucleation activation energy, and reducing the crystal growth rate, and achieves the effect of increasing the number of crystal nuclei and improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

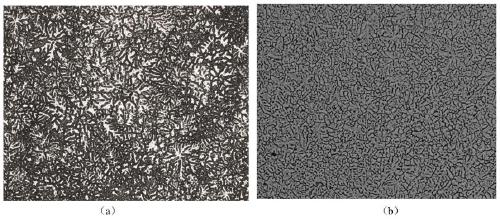

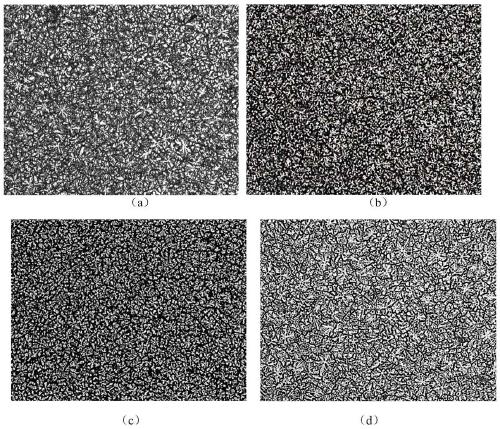

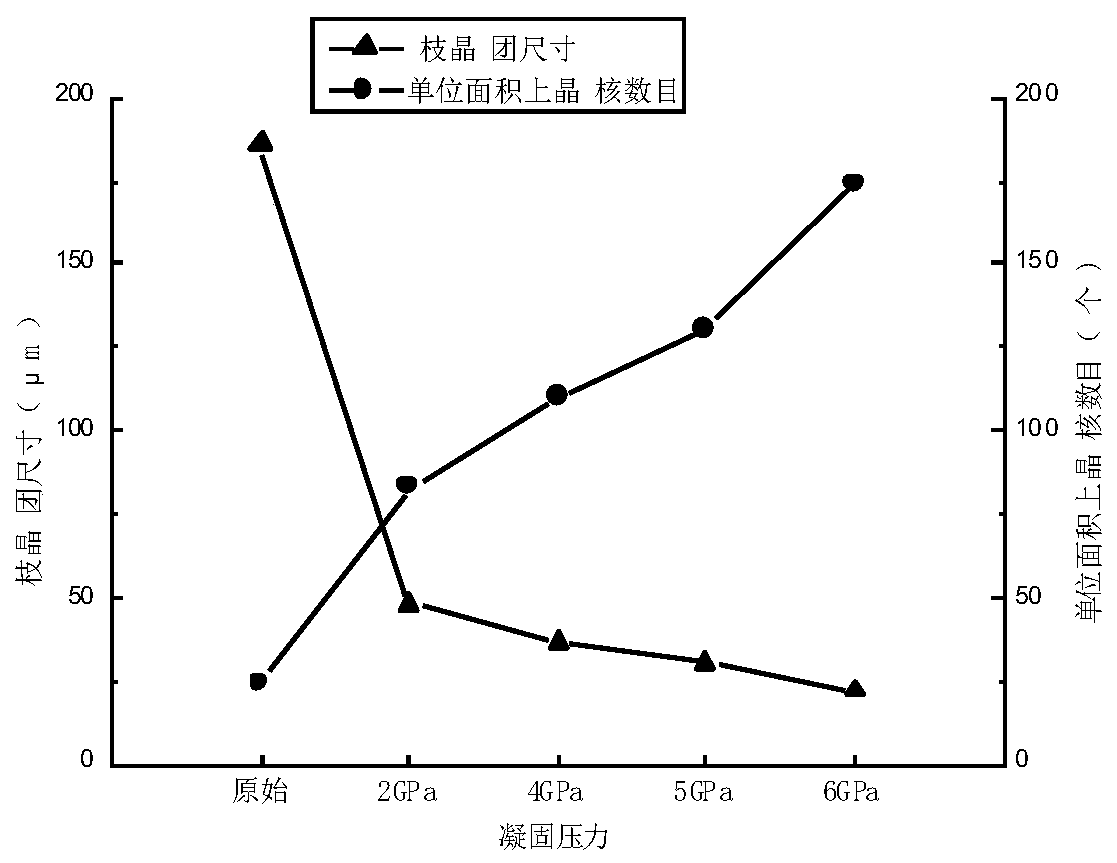

[0026] Main raw materials of Mg-Zn-Cu-Zr-(Cr-Ca) alloy used for smelting: Mg ingot, Zn ingot, brass with Cu-Zn ratio of 7:3, Mg-30% Zr and Mg-30% Ca intermediate Alloy and metal Cr, the purity of each component is 99.99%. The 2RRL-M8 vacuum resistance furnace is used for melting, the melting temperature is 760°C, and the pouring temperature is 730°C, and the melted alloy liquid is poured into the preheated metal mold to obtain an alloy ingot. The final composition (mass fraction, %) of the target alloy was analyzed by ICAP6300 plasma spectroscopy (IPP): 5.8% Zn, 0.45% Cu, 0.16% Zr, 0.15% Cr, 0.36% Ca, and the balance was Mg. After the target alloy ingot is homogenized and annealed, it is wire-cut into a high-pressure sample with a diameter of 8 mm and a length of 10 mm.

[0027] A CS-1V high-pressure six-sided top press was used for high-pressure experiments. Set the coagulation pressure to 2GPa ~ 6GPa. Melt superheat is one of the important factors affecting the solidifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com