Nano-composite material used for cotton ramie fabrics and preparation method thereof

A technology of nano-composite materials and cotton and linen fabrics, which is applied in the textile field, can solve the problems of environmental pollution, poor color fastness, and darkened shades of maintenance materials, and achieve the effects of enhanced dyeing performance, improved color fixation, and reasonable compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

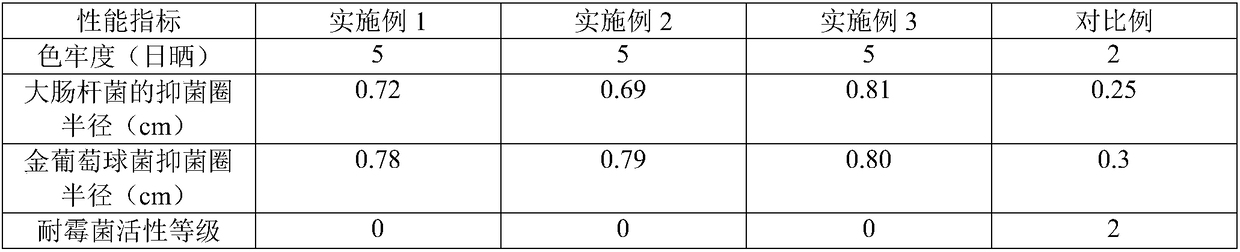

Examples

Embodiment 1

[0033] (1) Preparation of color-fixing modifier: take 1kg acetic acid and 7kg chitosan and mix uniformly respectively, and acylation reaction occurs to obtain cotton fiber modifier; get the madder extract obtained by the conventional biological extraction method as biomass Color-retaining agent, the cotton-linen fiber modifying agent and the biomass color-retaining agent that mass ratio is 1:1 are mixed uniformly, obtain color-fixing modifying agent, standby;

[0034] (2) Preparation of cross-linking agent: compounding genipin with a mass ratio of 1:4 and single-walled carbon nanotubes loaded with nano-silver particles on the surface to obtain a cross-linking agent for subsequent use;

[0035] (3) Preparation of modified nano-photocatalyst: intercalation modified hydrotalcite Mg with a mass ratio of 4:1 6 al 2 (OH) 16 CO 3 4H 2 O and nano g-C 3 N 4 Disperse in intercalated modified hydrotalcite, and after ultrasonic vibration treatment for 3 hours, a modified nano photoc...

Embodiment 2

[0038] (1) Preparation of color-fixing modifier: take 1kg acetic acid and 5kg chitosan and mix uniformly respectively, and acylation reaction occurs to obtain cotton and linen fiber modifier; get the camellia seed extraction obtained by the conventional biological extraction method of equal quality material, salicylic vine extract and madder extract are formulated into a biomass color-protecting agent, and the cotton-linen fiber modifying agent and the biomass color-protecting agent are mixed evenly with a mass ratio of 1:1 to obtain a color-fixing modifier, which is ready for use ;

[0039] (2) Preparation of cross-linking agent: compounding genipin with a mass ratio of 1:1 and single-walled carbon nanotubes loaded with nano-silver particles on the surface to obtain a cross-linking agent for subsequent use;

[0040] (3) Preparation of modified nano photocatalyst: intercalation modified hydrotalcite Mg with a mass ratio of 2:1 6 al 2 (OH) 16 CO 3 4H 2 O and nano g-C 3 N 4...

Embodiment 3

[0043] (1) Preparation of color-fixing modifier: take 1kg acetic acid and 8kg chitosan and mix uniformly respectively, and acylation reaction takes place to obtain cotton fiber modifier; get the camellia seed extraction obtained by the conventional biological extraction method of equal quality Compound h and Salicus vine extract are made into biomass color-protecting agent, and the cotton-linen fiber modifying agent and biomass color-protecting agent are mixed uniformly with a mass ratio of 1:1, to obtain color-fixing modifier, for subsequent use;

[0044] (2) Preparation of cross-linking agent: compounding genipin with a mass ratio of 1:5 and single-walled carbon nanotubes loaded with nano-silver particles on the surface to obtain a cross-linking agent for subsequent use;

[0045] (3) Preparation of modified nano-photocatalyst: intercalation modified hydrotalcite Mg with a mass ratio of 5:1 6 al 2 (OH) 16 CO 3 4H 2 O and nano g-C 3 N 4 Disperse in intercalated modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com