A Chemical Looping Combustion Air Reactor with Enhanced Oxidation and Regeneration of Oxygen Carriers

A technology of chemical looping combustion and air reactor, which is applied in the field of fluidized bed and multiphase flow, can solve the problems of low oxygen carrier oxidation regeneration efficiency, inconvenient manufacturing, and reduced reliability, so as to improve oxidation regeneration efficiency and prevent air bubble short circuit The effect of less phenomenon and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

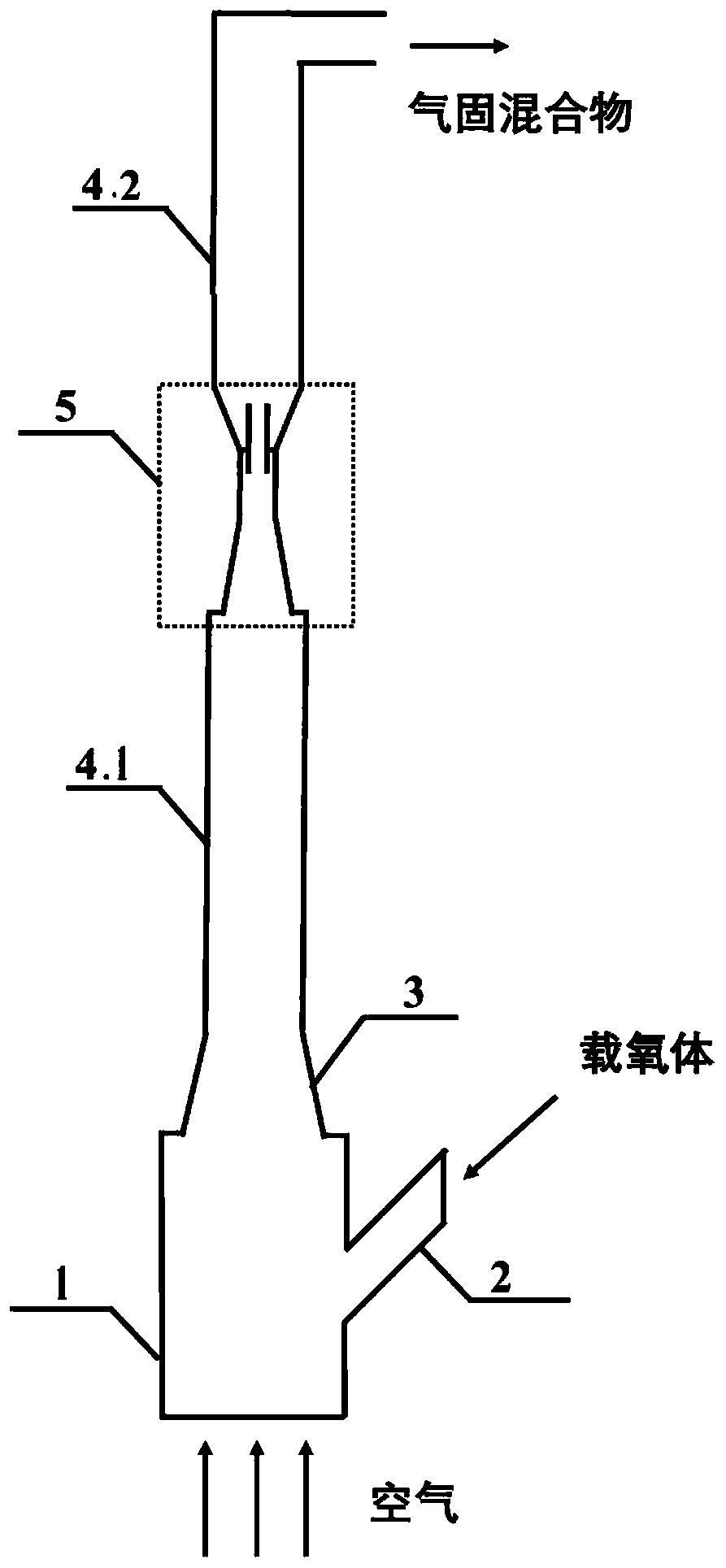

[0039] like Figure 1-5 As shown, a chemical looping combustion air reactor that strengthens oxidation and regeneration of oxygen carriers includes a reaction chamber 1, a first riser 4.1, a composite internal member 5 and a second riser 4.2;

[0040] The side wall of the reaction chamber 1 is provided with a feeding port 2, and the bottom is provided with an air inlet;

[0041] The first reducer 3 is used to connect the reaction chamber 1 and the first riser 4.1;

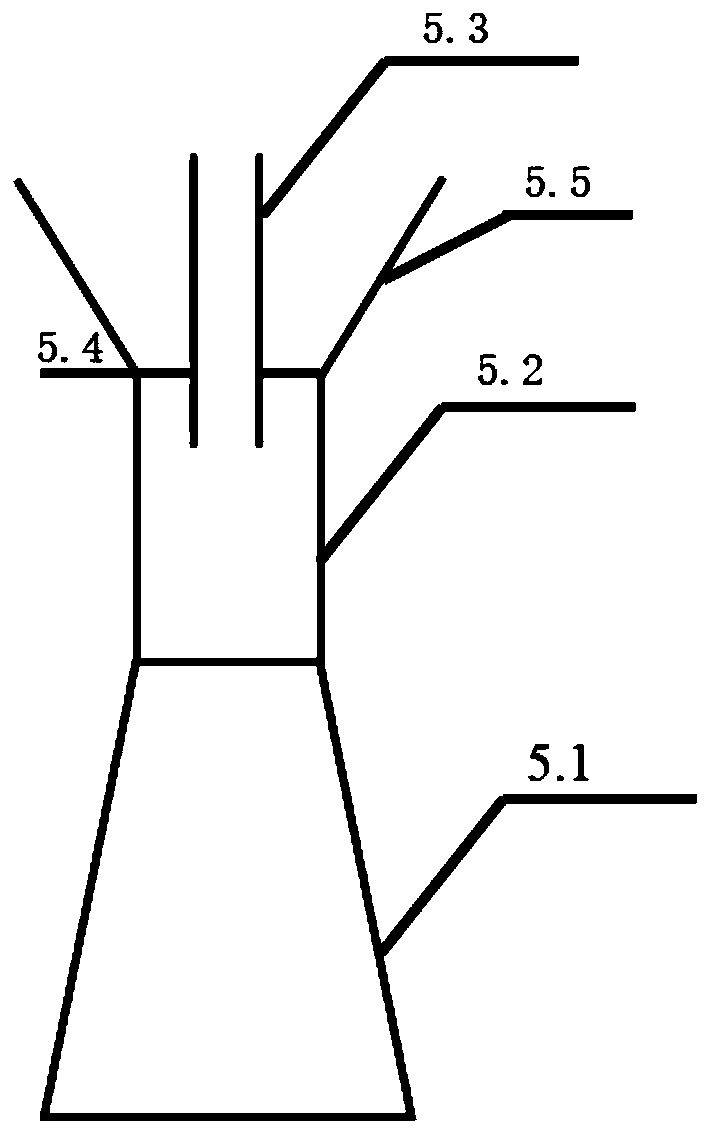

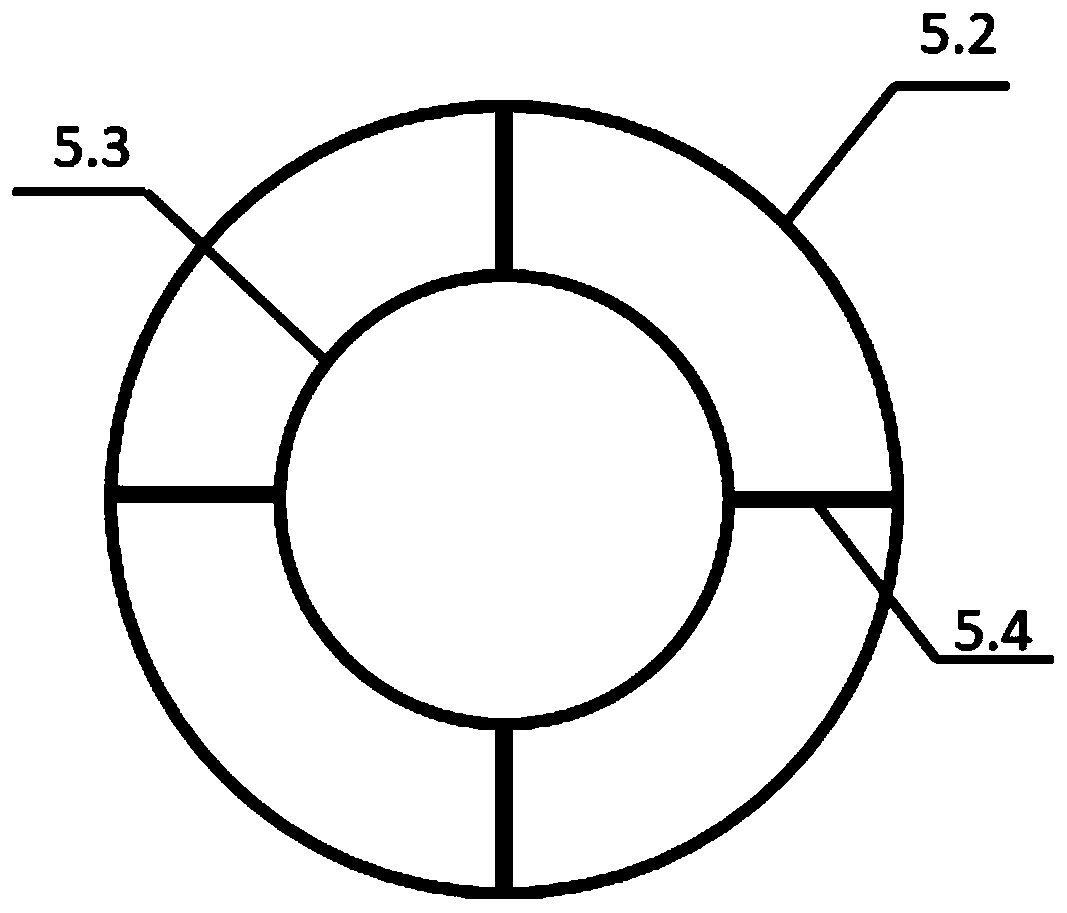

[0042] A composite inner member 5 is installed between the first riser 4.1 and the second riser 4.2; the composite inner member 5 includes a second reducer 5.1, an annular inner member 5.2, a guide pipe 5.3, and a support plate 5.4 And the inclined annular inner member 5.5; the upper part of the second reducer 5.1 is connected with the lower part of the annular inner member 5.2, the lower part of the second reducer 5.1 is connected with the upper part of the first riser 4.1, and the guide pipe 5.3 is vertically inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com