Natural ventilation counter flow cooling tower

A natural ventilation, counter-flow technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc. Wind unevenness and other problems, to achieve the effect of improving the unevenness of wind speed distribution, improving efficiency, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

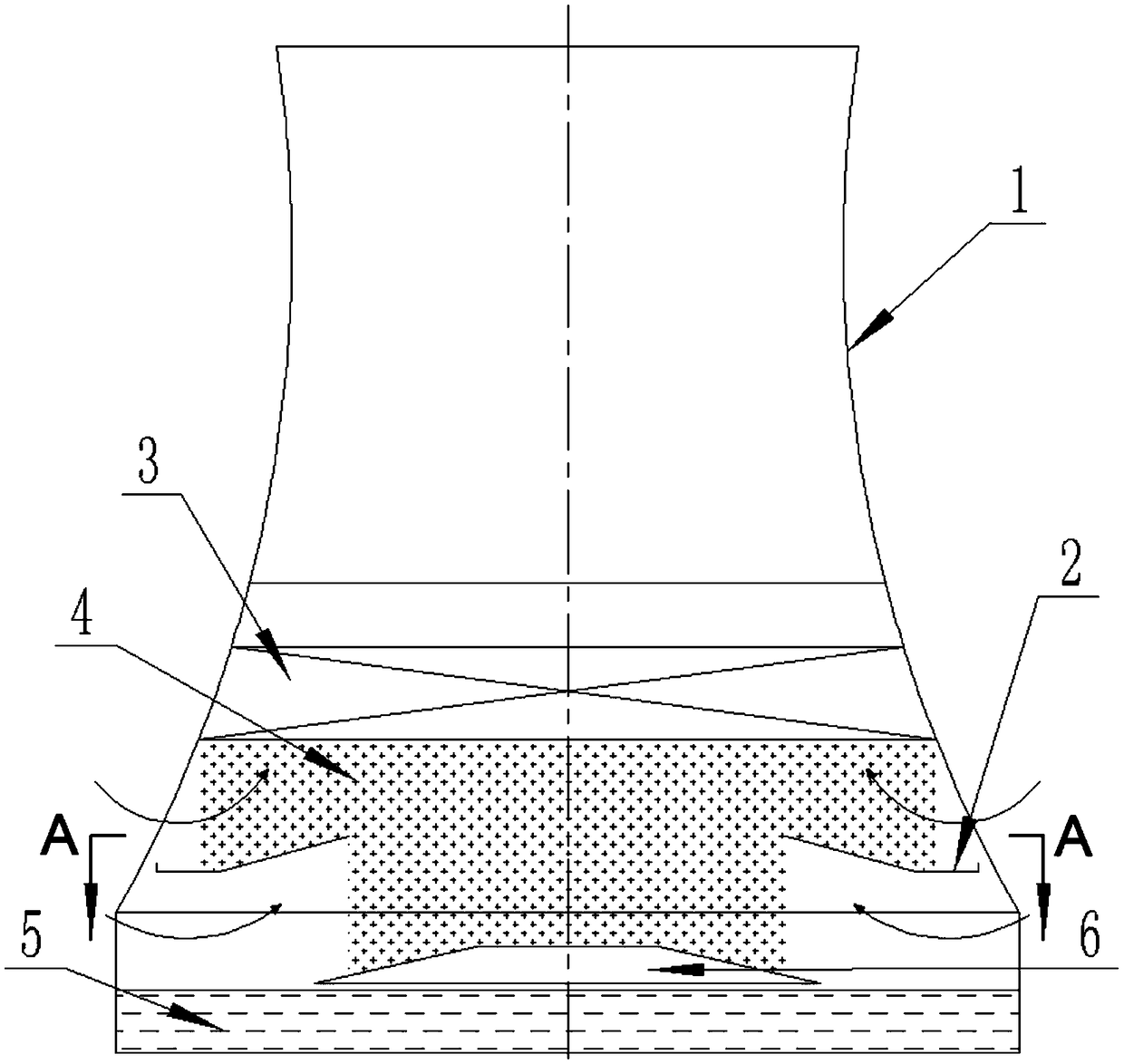

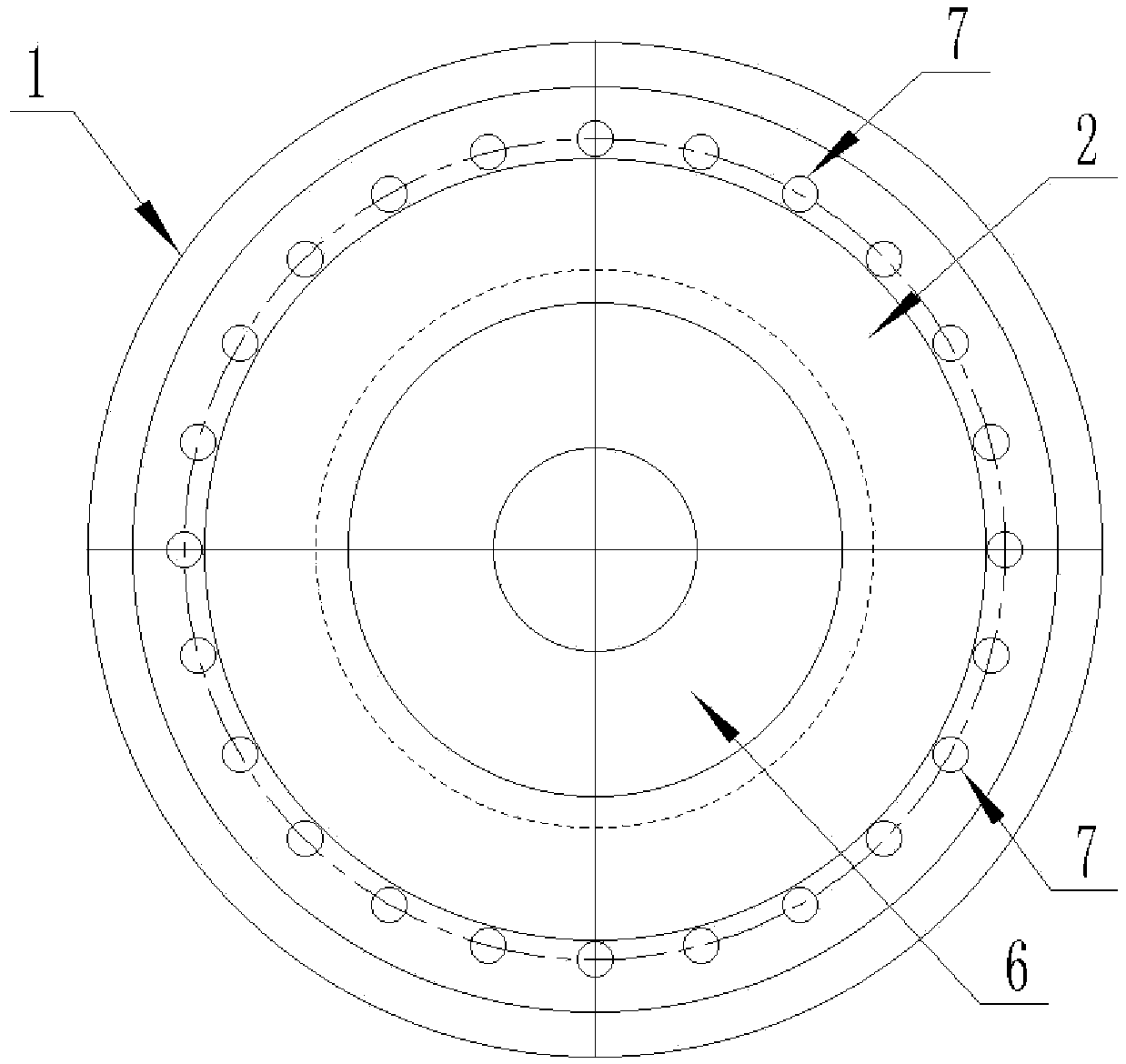

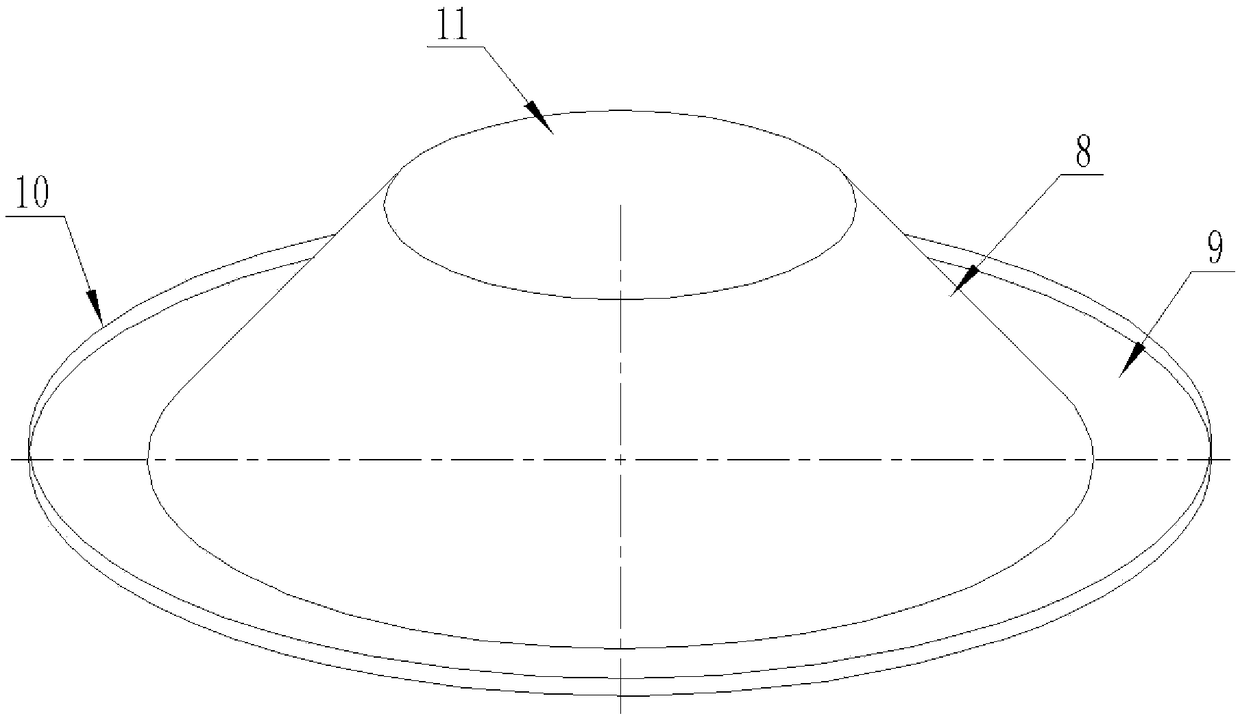

[0045] A natural ventilation counter-flow cooling tower, comprising a tower shell 1, the tower shell 1 is provided with an air inlet deflector 2, and the air inlet deflector 2 contains a cylindrical section 8, a circular cylinder section connected in sequence from the inside to the outside The ring section 9 and the water retaining section 10, the cylinder section 8 is an upright truncated conical cylindrical structure, the ring section 9 is a concentric ring structure in a horizontal state, the water retaining section 10 is an upright cylindrical structure, and the cylinder The top of the section 8 faces upwards, the top of the cylindrical section 8 is provided with ventilation holes 11, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com