Ultrasonic scanning device, application thereof and method

A scanning device, ultrasonic technology, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. , does not have problems such as fluidity, and achieves the effect of high-precision and rapid ultrasonic scanning analysis, improving consistency, and eliminating defective batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

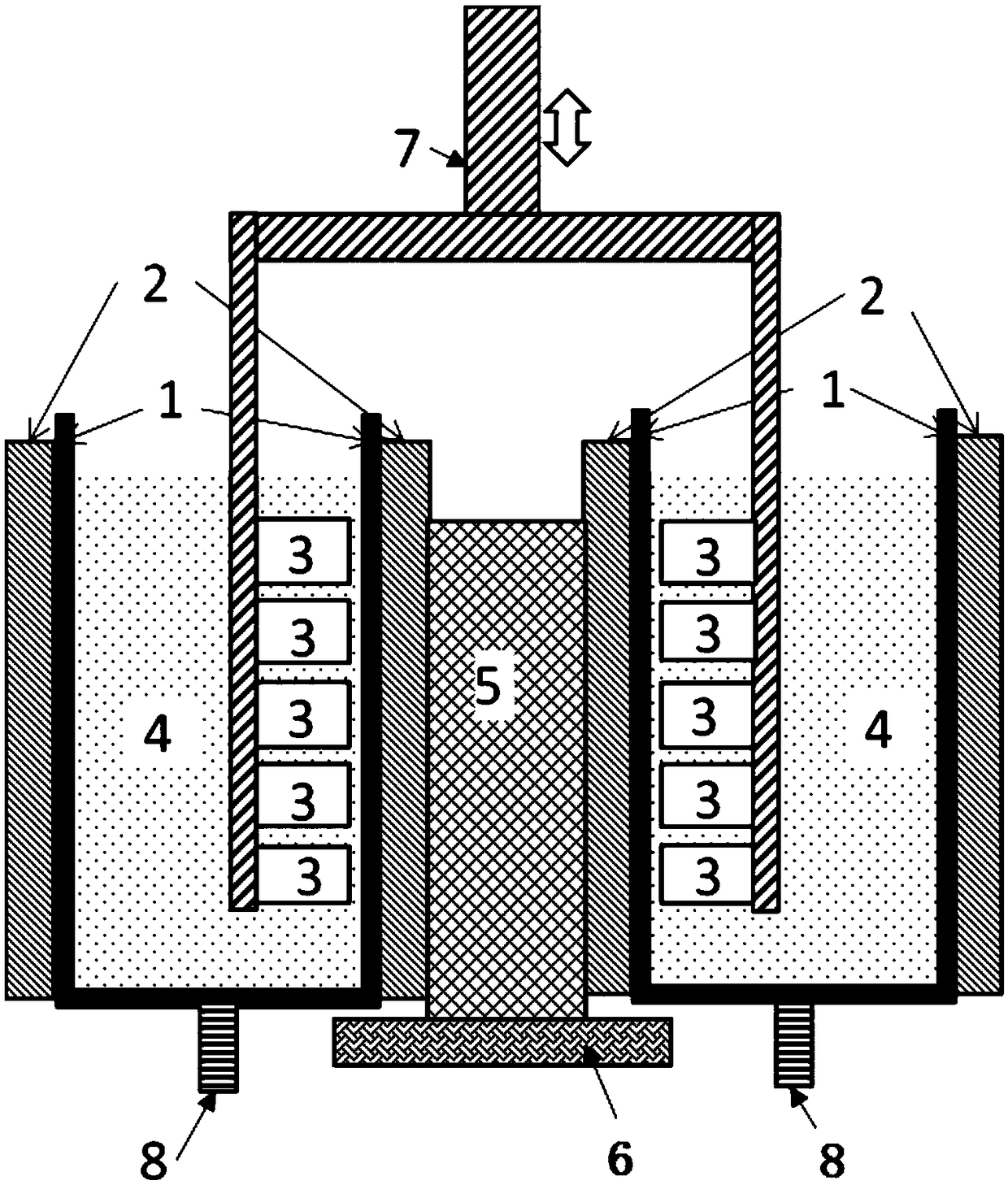

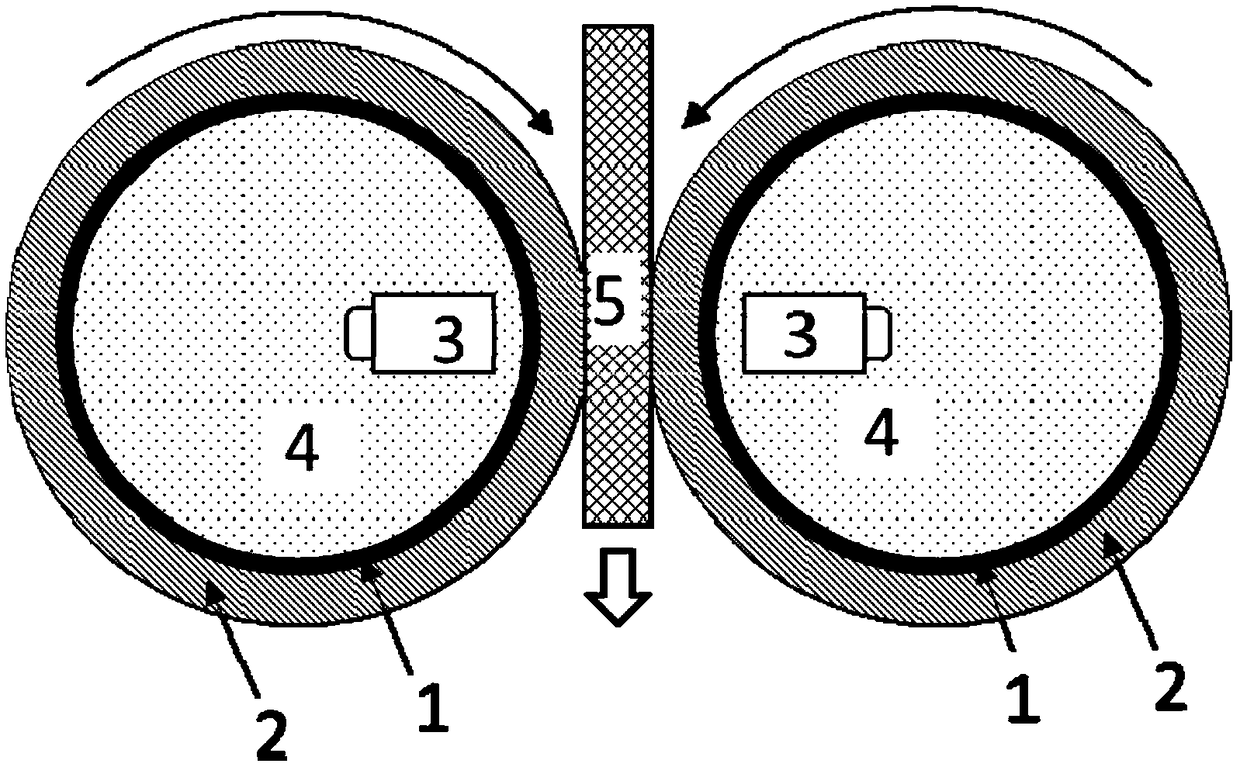

[0047] Example 1 A Vertical Tube Type Ultrasonic Scanning Device for Detecting Internal Defects in a Prismatic Battery

[0048] Square aluminum shell lithium-ion battery is a common type of battery in the current power battery market. It has a square appearance, and inside is a multi-layer electrode material, separator, and current collector that are wound or laminated, and are infiltrated by electrolyte. The use of ultrasonic waves can detect internal pole piece defects, electrolyte injection distribution, internal gas, etc., which is of great significance to ensure battery quality. In this embodiment, a square aluminum case lithium-ion battery with a size of 150mm x 100mm x 30mm is used as the object to be tested.

[0049] The inner wall of the drum is made of plexiglass, with an outer diameter of 200mm, a wall thickness of 3mm, and a height of 300mm. The bottom is closed and the upper end is open. The axial direction is perpendicular to the horizontal plane. A layer of 10mm...

Embodiment 2

[0059] Example 2 A Vertical Tube Type Ultrasonic Scanning Device for Detecting Internal Defects of a Square Rubber Block

[0060] In this embodiment, a square rubber block with a size of 150mm x 100mm x 50mm is used as the object to be tested. Most of the structure of the ultrasonic scanning device is the same as that of Embodiment 1, only the following changes are made:

[0061] Since the item to be tested is elastic and its overall thickness is 20mm thicker than that of the square battery in Example 1, the outer walls of the two rollers do not need silicone rubber, and the inner wall of the plexiglass roller is directly in contact with the item to be tested. The deformation makes it pass through the roller gap with a pitch of 49mm.

[0062] The thickness of the item to be tested is relatively thick in the z direction, and it is relatively stable when placed on the transfer belt, so the width of the conveyor belt is changed to 45mm, and its position is raised to be higher th...

Embodiment 3

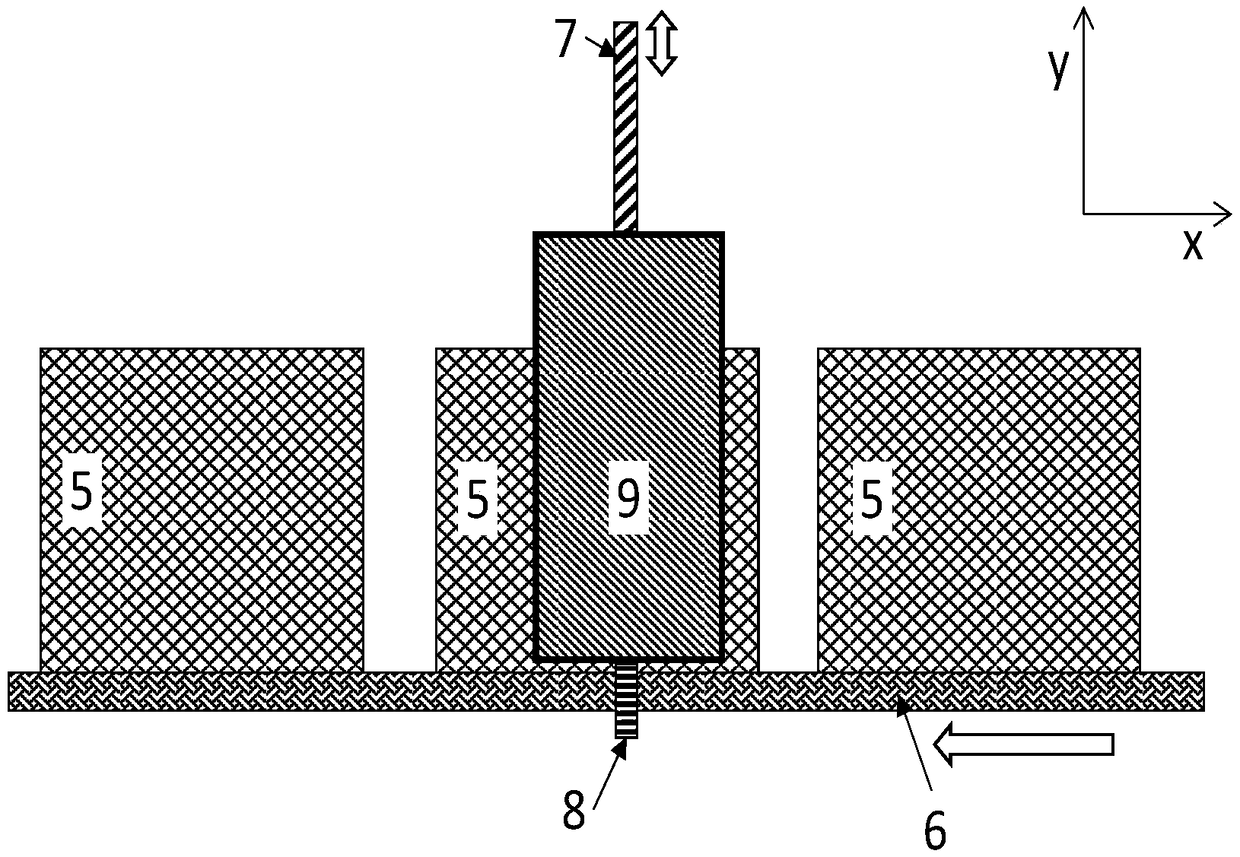

[0065] Example 3 Horizontal oblique cylinder type ultrasonic scanning device for detecting internal defects of pouch batteries

[0066] Soft-pack lithium-ion batteries are also a common form of battery on the market. The appearance is usually square, but unlike square aluminum-case batteries, the packaging material is aluminum-plastic film, and the interior is usually multi-layer electrode materials manufactured by lamination technology. Diaphragm, collector, soaked by electrolyte. Its thickness is usually less than 15mm, and the edge is a folded structure of aluminum-plastic film, which cannot be placed vertically on the conveyor belt. In order to solve the continuous scanning problem of the soft-packed lithium-ion battery, the invention discloses an oblique cylinder type ultrasonic scanning device.

[0067] Different from the vertical cylinder type ultrasonic scanning device described in Embodiment 1, in the parallel-arranged oblique cylinder type ultrasonic scanning device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com