Method for removing plasticizer from extract

A technology of plasticizers and extracts, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve problems such as increasing the difficulty of sewage treatment, application restrictions, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

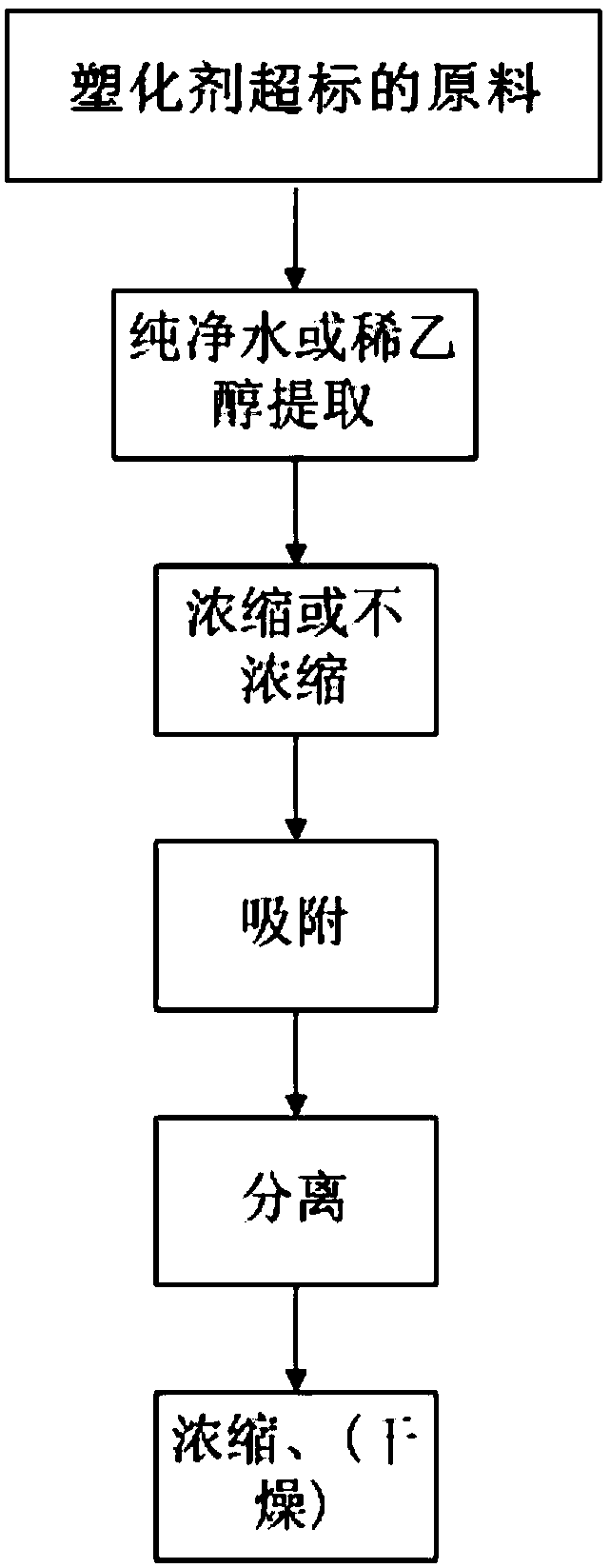

Method used

Image

Examples

Embodiment 1

[0032] (1) Extraction: Put 300 kg of Epimedium medicinal materials into a 5400L multifunctional extraction tank, add 4800L of pure water to decoct, the decoction temperature is (98±2)℃, and the decoction time is (1.5±0.5) hours. The number of times of cooking is 3 times, the extracts are combined, and the disc centrifuge is used for high-speed centrifugation at a speed of 6000r / min or more to obtain the centrifugate. The centrifugate is required to be clear and transparent, and the precipitate after centrifugation is directly discharged.

[0033] (2) Concentration: the centrifuged extract is concentrated under reduced pressure using a double-effect concentrator, the concentration temperature is (65-80)°C, and the concentration is concentrated to a Brix value of (10±2)%.

[0034] (3) Adsorption: Transfer the concentrated solution to a stirring container, add 3.0 kg of activated carbon, and keep stirring at (50-60)°C for 0.5 hours.

[0035] (4) Separation: use ceramic membrane t...

Embodiment 2

[0039] (1) Dissolving: add 400L food-grade 25% ethanol in the 500L multifunctional extraction tank, drop into 20 kilograms of Epimedium extract (icariin content is 10.5%) that the plasticizer exceeds the standard under stirring, be warming up to 80 ℃ And keep warm and stir to dissolve, the dissolution time is 0.5 hours.

[0040] (2) Adsorption: Lower the temperature of the feed liquid to 50°C, add 0.5 kg of molecular sieve, and keep stirring at 50°C for 1 hour.

[0041] (4) Separation: filter with a sealed plate and frame filter press to collect the clarified liquid; and use 50 L of food-grade 25% ethanol for top washing to obtain a total of 420 L of feed liquid.

[0042] (5) Concentration: The clarified liquid obtained by ceramic membrane filtration is concentrated under reduced pressure with a double-effect concentrator at a concentration temperature of (60-80)°C to a relative density of 1.08-1.12.

[0043] (6) Drying: Use a spray dryer to dry, control the inlet air temperatu...

Embodiment 3

[0045] (1) Extraction: Put 600 kg of crushed peach kernels into a 5400L multifunctional extraction tank, add 4800L food-grade 50% ethanol for extraction, the extraction temperature is (80±2)°C, the extraction time is 1.5 hours, and the number of extractions is 3 times. Combine the extracts, and use a disc centrifuge for high-speed centrifugation at a speed of 6000 r / min or more to obtain a centrifuge. The centrifuge is required to be clear and transparent, and the precipitate after centrifugation is directly discharged.

[0046] (2) Adsorption: Transfer the extract to a container with stirring, add 6.0 kg of carbon molecular sieves, and keep stirring at (50-60)°C for 1.0 hour.

[0047] (3) Separation: filter with a ceramic membrane to collect the clarified liquid; and use 500 L of food grade 50% ethanol for top washing to obtain a total of 13500 L of feed liquid.

[0048] (5) Concentration: The clarified liquid obtained by ceramic membrane filtration is concentrated under redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com