An easy-to-clean dust filter bag

A filter bag and dust removal technology, which is applied in the direction of filtration and separation, dispersed particle filtration, separation methods, etc., can solve the problems of insufficient cleaning of secondary dust and damage of primary dust, and achieve high production efficiency, simple manufacturing process, The effect of facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

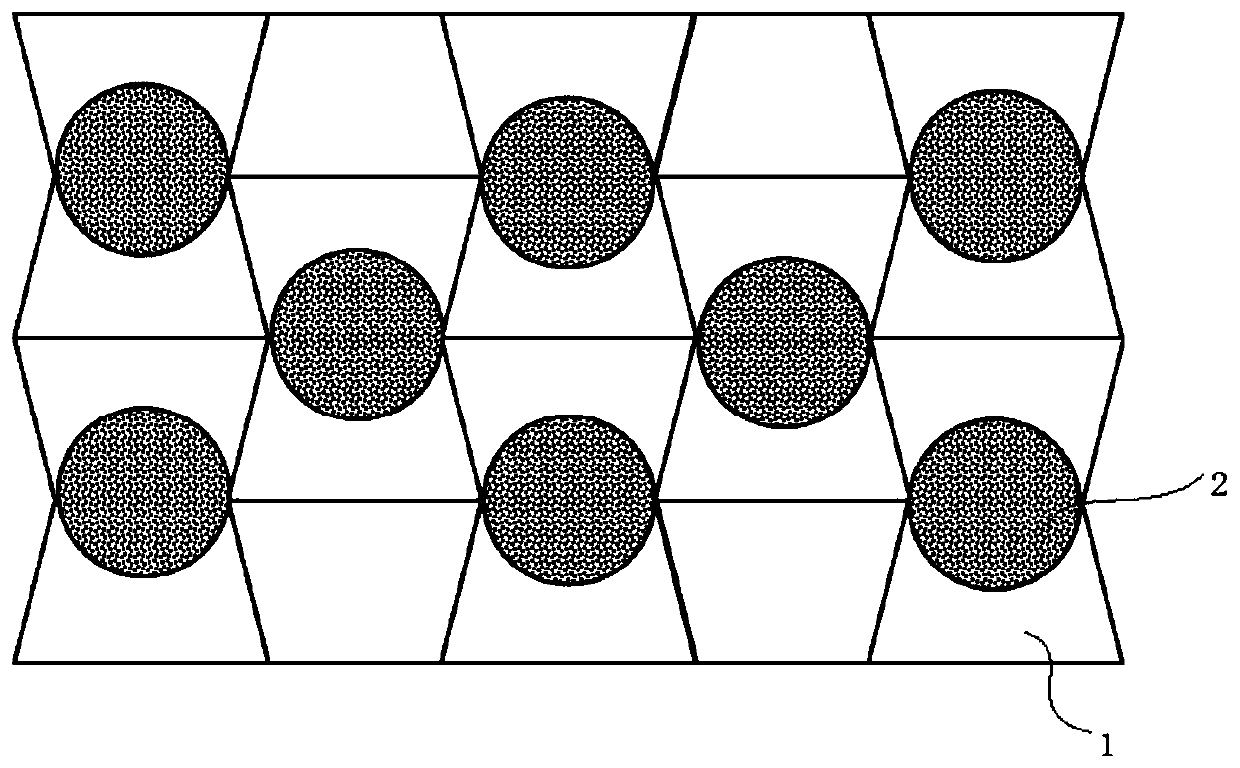

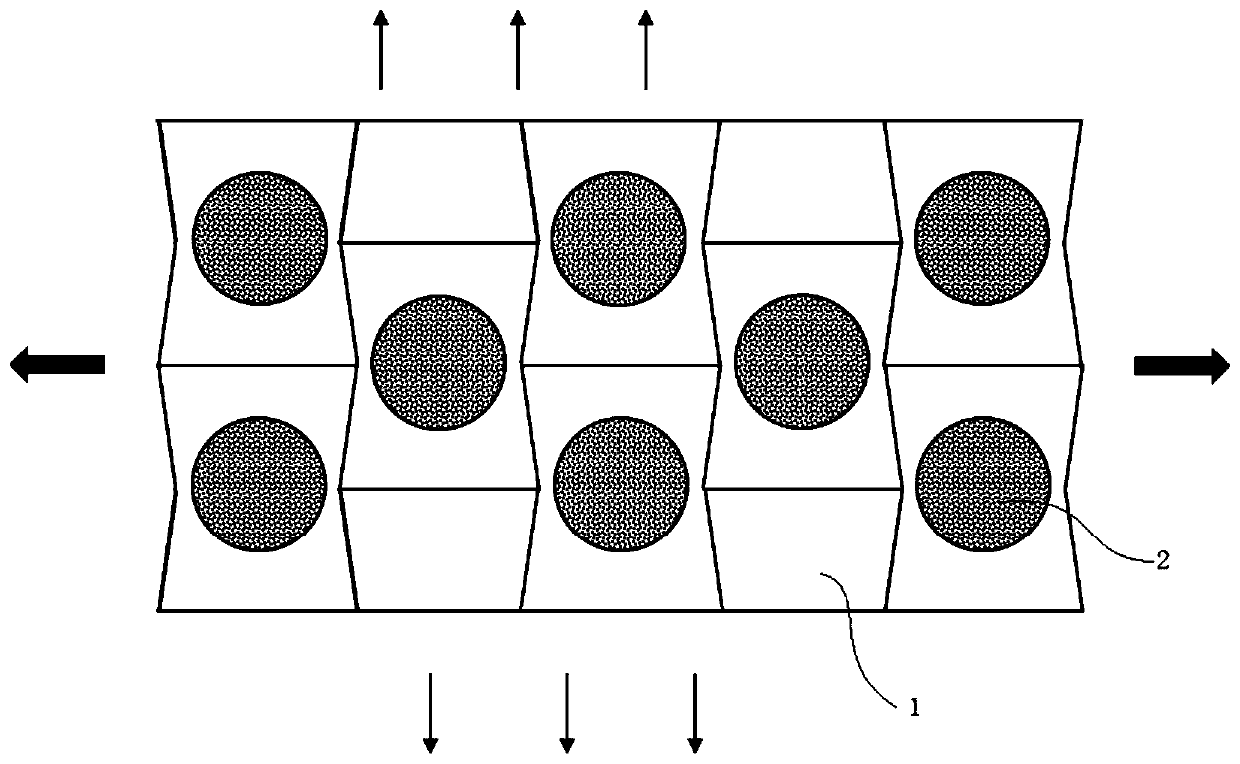

[0032] An easy-to-clean filter bag, characterized in that the filter material used to prepare the filter bag includes a base cloth layer 1 and a fiber web layer, the base cloth layer has a negative Poisson's ratio, and the fiber web layer is needle-punched The process is compounded on the base cloth layer (the structure of the filter material is not shown).

[0033] Preferably, the fiber web layer is arranged on one side of the base cloth layer, and the fiber web is compounded on one side of the base cloth layer through a needling process.

[0034] Preferably, the fiber web layers are respectively arranged on both sides of the base cloth layer, and the fiber webs are compounded on both sides of the base cloth through a needling process, thereby forming a sandwich structure.

[0035] Preferably, the fineness of the fibers selected in the fiber ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com