Device for testing spectral emissivity of material in high-temperature direction

A technology of spectral emissivity and testing device, which is applied in the field of spectral emissivity testing device in high temperature direction of materials, can solve the problems of large space occupied by ultra-high temperature heating furnace and inflexible movement mechanism, and achieves simplified structure, reduced space occupation, Avoid the effect of high temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

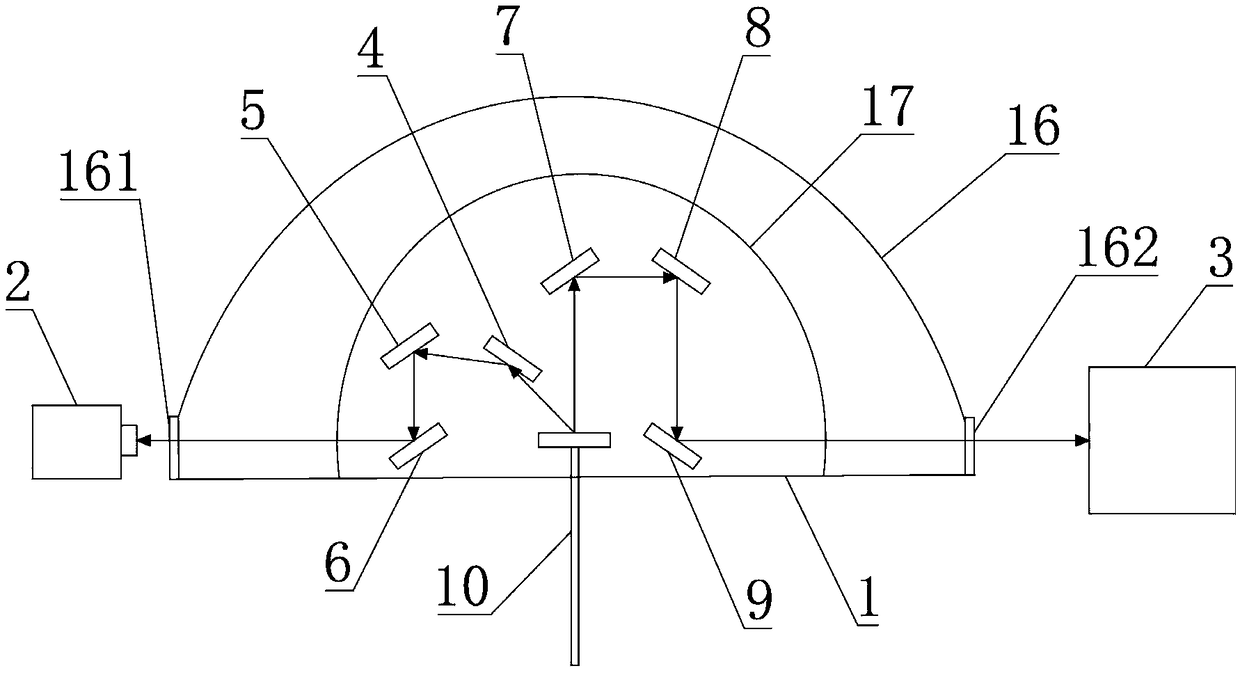

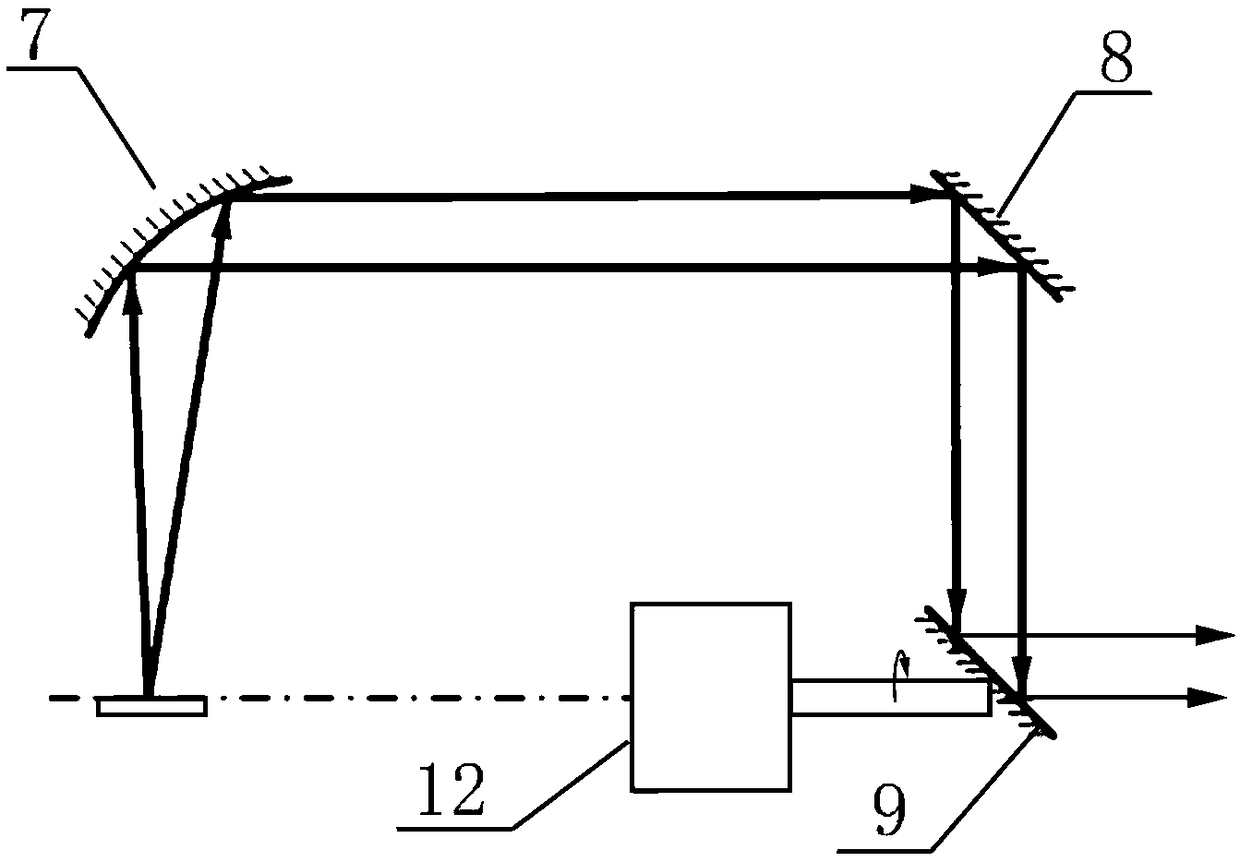

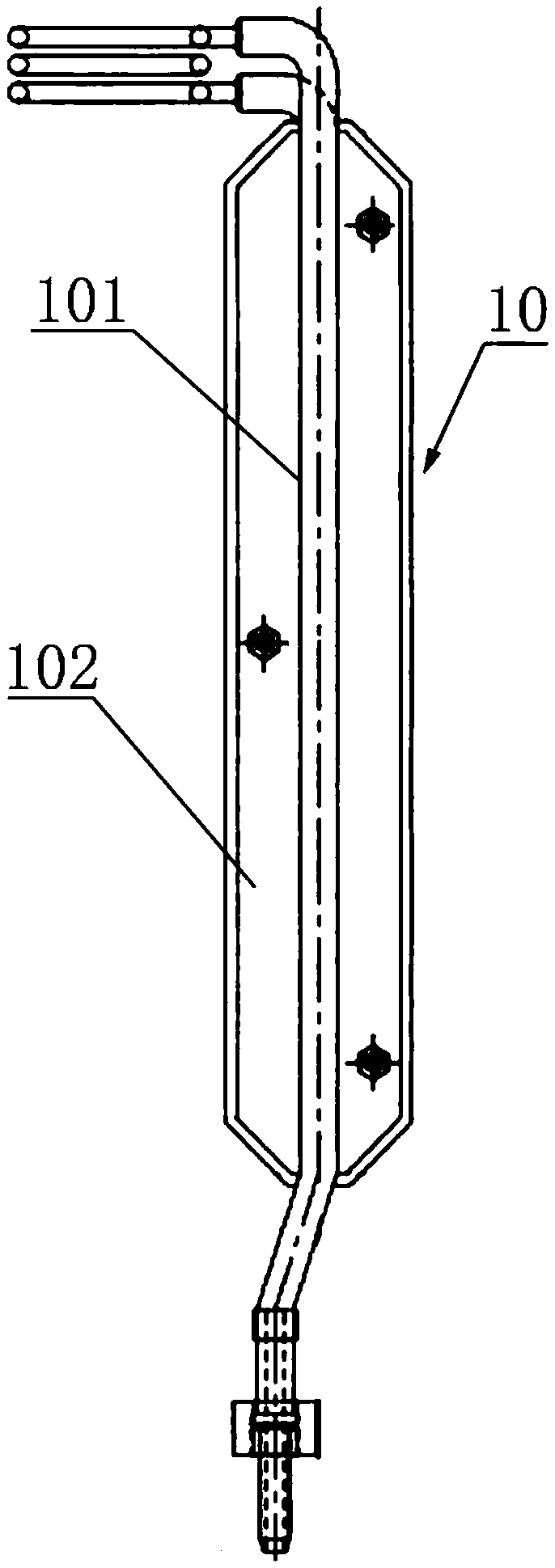

[0044] Such as figure 1As shown, a material high-temperature spectral emissivity testing device provided by an embodiment of the present invention includes a workbench 1, an electromagnetic induction heating system 10, a temperature measuring optical system and a radiation measuring optical system, a temperature measuring device 2 and a Fourier spectrometer 3, Wherein the workbench 1 is provided with a support portion for placing the test piece, the heating head of the electromagnetic induction heating system 10 passes through the workbench 1 from the underside of the workbench 1, and is located near the support portion, and can be placed on the support portion The test piece is heated. The temperature measurement optical path system is installed above the workbench, and can collect the radiation of the DUT, and transmit the collected DUT radiation to the temperature measuring device 2 . The radiation measurement optical path system is installed above the workbench through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com