Thermal decomposition device and test method for high-boiling-point clean extinguishing agent in air atmosphere

A fire extinguishing agent and thermal decomposition technology, which is applied in the thermal decomposition device field of high boiling point and low greenhouse effect clean chemical liquid fire extinguishing agent, can solve problems such as differences in thermal decomposition of fire extinguishing agents, incomplete vaporization of liquid fire extinguishing agents, etc., and achieve strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

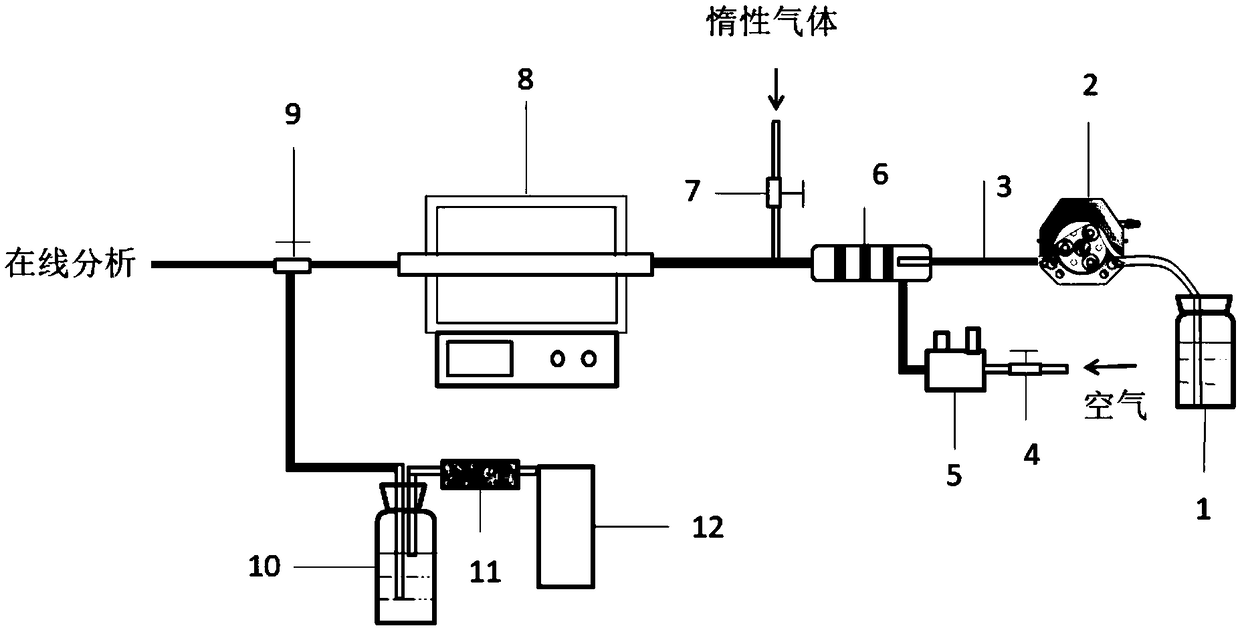

[0048] like figure 1 As shown, a high boiling point clean fire extinguishing agent thermal decomposition device in air atmosphere, including: liquid fire extinguishing agent and glass container 1, peristaltic pump 2, heating belt and temperature controller 3 of heating belt, valve 1 4, gas flow meter 5. Vaporization chamber 6, valve 2 7, tube furnace 8, valve 3 9, ion hand sanitizer 10, gas drying device 11, and gas collection bag 12.

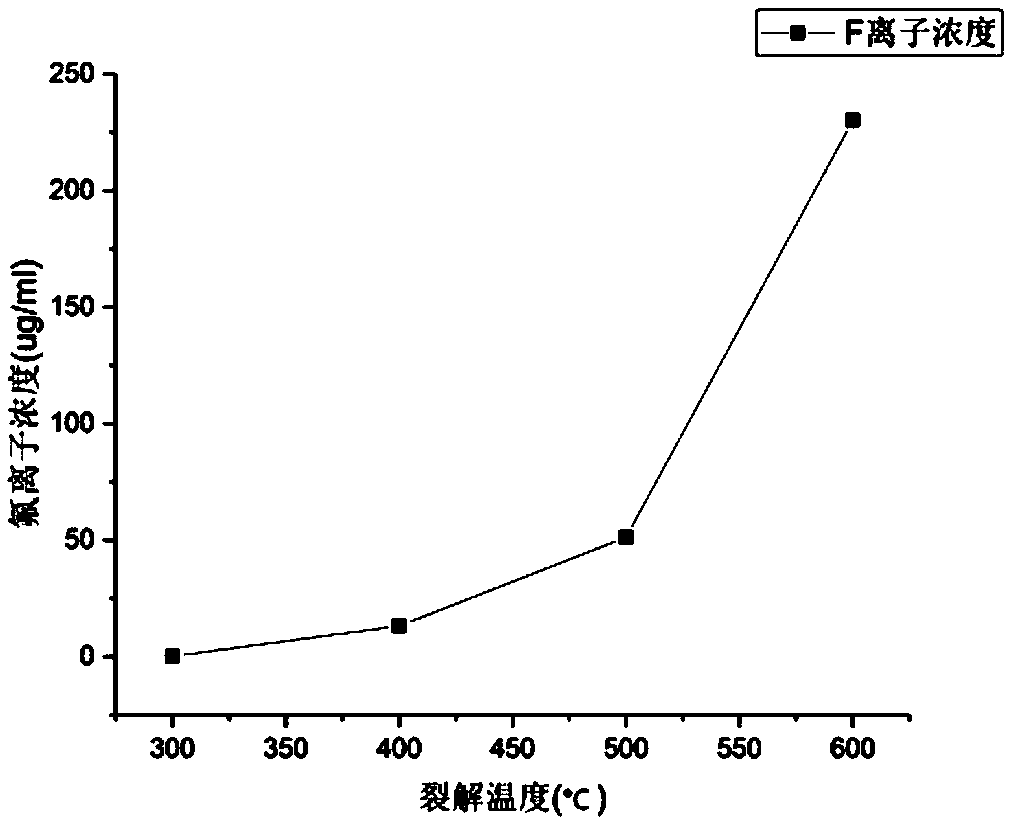

[0049] Open the inert gas cylinder valve in the device, i.e. valve two 7 and adjust the valve to feed inert gas to the tube furnace 8 at a certain flow rate, open the tube furnace 8 and set the pyrolysis temperature (the thermal decomposition temperature of perfluorohexanone is set to 300 Between 50°C and 850°C, set the temperature gradient according to 50°C or 100°C), keep the temperature in the constant temperature zone in the tube furnace for 1 to 3 hours, and then close the valve 27 of the inert gas cylinder. Next, turn on the heating belt...

Embodiment 2

[0051] In the present invention, the high-boiling clean fire extinguishing agent can be replaced with a liquid refrigerant. Formally hexafluorobutene (HFO-1336mzz(Z)) is a new type of halogenated hydrocarbon developed by DuPont Company of the United States. Due to its excellent thermodynamic properties, non-flammability, low toxicity, and environmental friendliness (ODP= 0, GWP=2), its boiling point is 33.4°C. Its physical and chemical properties are very similar to those of perfluorohexanone (Novce 1230). The thermal stability and pyrolysis products of liquid refrigerants can also be analyzed with the pyrolysis device of this patent.

[0052] Open the inert gas cylinder valve in the device, i.e. valve two 7 and adjust the valve to feed inert gas into the tube furnace 8 at a certain flow rate, open the tube furnace 8 and set the pyrolysis temperature (the thermal decomposition temperature of formal hexafluorobutene is set to Between 300°C and 800°C, set the temperature gradie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com