Pretreatment process suitable for high-aluminum hybrid car body of original equipment manufacturer

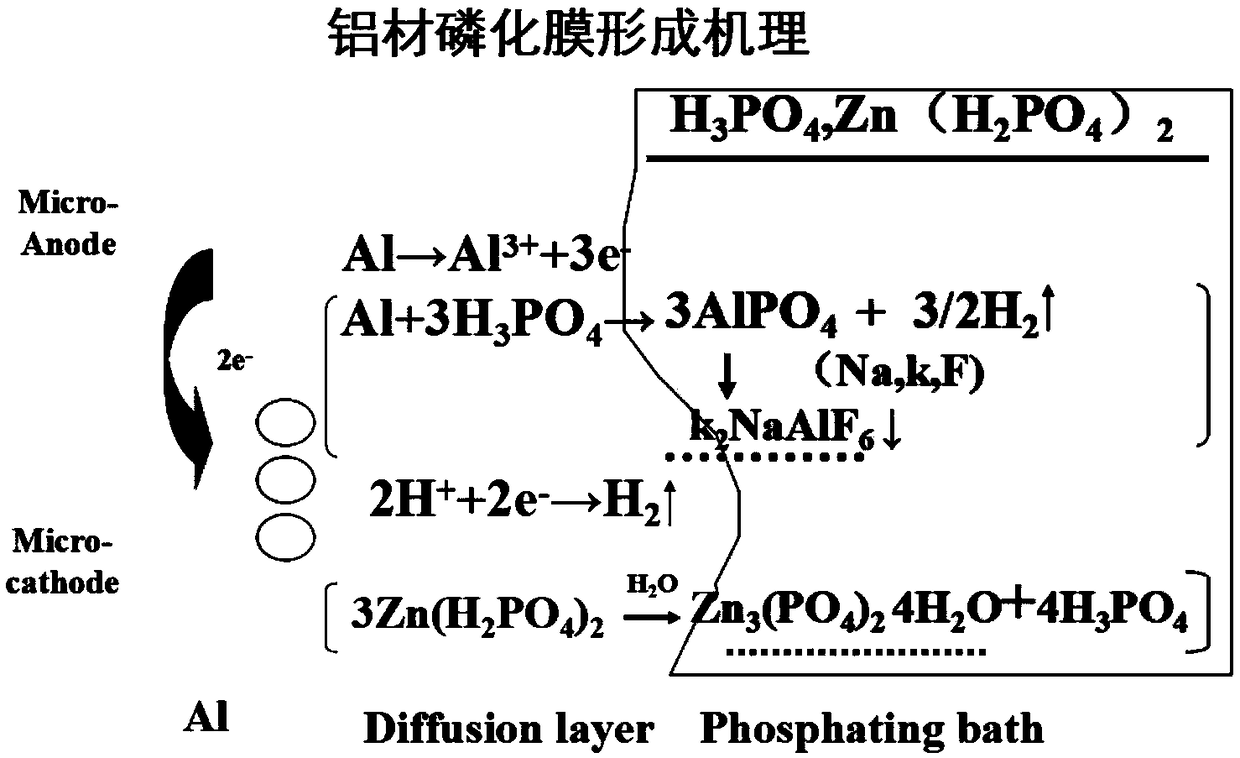

A technology of high-alumina and body, which is applied in the field of pre-treatment process of high-aluminum mixed body, to achieve the effect of dense and complete film weight, uniform and dense film formation, and easy filtration and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 A pre-treatment process suitable for high-aluminum hybrid car bodies of OEMs

[0047] In this example, the aluminum plate of the high-aluminum hybrid body of the OEM is used as a model, and the pretreatment process experiment is carried out.

[0048] (1) The pretreatment process includes the following steps:

[0049] 1) Hot water wash

[0050] Spray the aluminum plate with hot water at 42-48°C for 90-100s.

[0051] 2) Pre-degreasing

[0052] The aluminum plate washed with hot water is sprayed with a degreasing agent at 42-48°C for 60-70s;

[0053] 3) Degreasing treatment

[0054] The pre-degreased aluminum plate is immersed in a degreasing agent at 42 to 48° C. for degreasing treatment for 60 to 70 s.

[0055] The degreaser is made by mixing A and B in a weight ratio of 2:1.

[0056] Agent A, by weight percentage, is composed of 12% sodium metasilicate, 21% potassium carbonate, 10% sodium hydroxide, 3% EDTA-4Na, 5% acrylic acid homopolymer, and the balance...

Embodiment 2

[0085] Example 2 A pre-treatment process suitable for high-aluminum hybrid car bodies of OEMs

[0086] In this embodiment, the high-aluminum hybrid body of the OEM is composed of galvanized sheet, cold-rolled sheet and aluminum sheet, wherein the proportion of aluminum sheet (the percentage of area occupied by the aluminum sheet) is 40%.

[0087] (1) The pretreatment process includes the following steps:

[0088] 1) Hot water wash

[0089] Spray the high-aluminum hybrid body with hot water at 42-48°C for 90-100s.

[0090] 2) Pre-degreasing

[0091] Spray the high-aluminum hybrid body after hot water washing with a degreasing agent at 42-48°C for 60-70s;

[0092] 3) Degreasing treatment

[0093] The pre-degreased high-alumina hybrid body is subjected to degreasing treatment of spraying before entering the tank, dipping into the tank and spraying after the tank is discharged. That is, spray with a degreaser at 42-48°C for 10-15s before entering the tank, immerse it in a deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shock proof | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com