Formula and application of working solution for electrokinetic remediation of antimony contaminated soil

A technology of polluted soil and electric restoration, which is applied in the field of soil restoration to achieve the effects of improving ion exchange capacity, improving the removal rate of antimony, and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

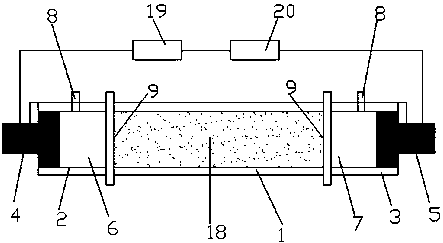

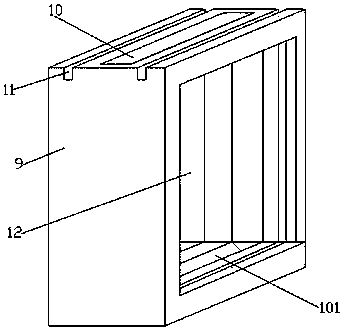

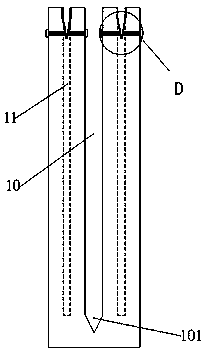

Method used

Image

Examples

Embodiment 1

[0046] Prepare a 1:1 0.05mol / L potassium dihydrogen phosphate-potassium hydroxide solution and a 1:1 0.2mol / L buffer solution. In the electric repair reaction device, the iron plate is used as the anode, and the steel plate is used as the cathode, and a DC power supply is used for regular intermittent power supply, and the current density is 1mA / cm 2 , the ratio of plate area to reactor side area is 1 / 2 m 2 / m 2 , The plate spacing is 15cm. Add 0.05 mol / L potassium dihydrogen phosphate-potassium hydroxide solution to the anode tank, and add 0.1 mol / L buffer solution to the cathode tank. The addition method is one-time addition, and samples are taken every 2 hours. Turn on the DC power supply, turn on the power for 2 hours, then cut off the power for 2 hours, and stop the power supply after 72 hours. It is measured that the removal rate of antimony in the soil reaches 30%.

Embodiment 2

[0048] Prepare a 1:1 0.5mol / L potassium dihydrogen phosphate-potassium hydroxide solution and a 1:1 0.8mol / L buffer solution. In the electric repair reaction device, the iron plate is used as the anode, and the steel plate is used as the cathode, and a DC power supply is used for regular intermittent power supply, and the current density is 1mA / cm 2 , the ratio of plate area to reactor side area is 1 / 2 m 2 / m 2 , The plate spacing is 15cm. Add 0.5 mol / L potassium dihydrogen phosphate-potassium hydroxide solution to the anode tank, and add 0.8 mol / L buffer solution to the cathode tank. The addition method is one-time addition, and samples are taken every 2 hours. Connect the DC power supply, turn on the power for 2 hours, then cut off the power for 2 hours, and stop the power supply after 72 hours. The removal rate of antimony in the soil is measured to reach 41%.

Embodiment 3

[0050] Prepare a 1:1 0.5mol / L potassium dihydrogen phosphate-potassium hydroxide solution and a 1:1 0.8mol / L buffer solution. In the electric repair reaction device, the iron plate is used as the anode, and the steel plate is used as the cathode, and a DC power supply is used for regular intermittent power supply, and the current density is 15mA / cm 2 , the ratio of plate area to reactor side area is 1 / 2 m 2 / m 2 , The plate spacing is 25cm. Add 0.5 mol / L potassium dihydrogen phosphate-potassium hydroxide solution to the anode tank, and add 0.8 mol / L buffer solution to the cathode tank. The addition method is one-time addition, and samples are taken every 2 hours. Connect the DC power supply, turn on the power for 4 hours, then cut off the power for 4 hours, and stop the power supply after 72 hours. The removal rate of antimony in the soil is measured to reach 50.9%.

[0051] The following table is the concentration of antimony in the soil after restoration using Examples 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com