Double-row plastic spoon connected packaging machine and packaging method

A packaging machine and plastic technology, applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of reduced work efficiency, low packaging efficiency, poor packaging quality, etc., and achieve improved work efficiency, improved packaging efficiency, and improved packaging. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

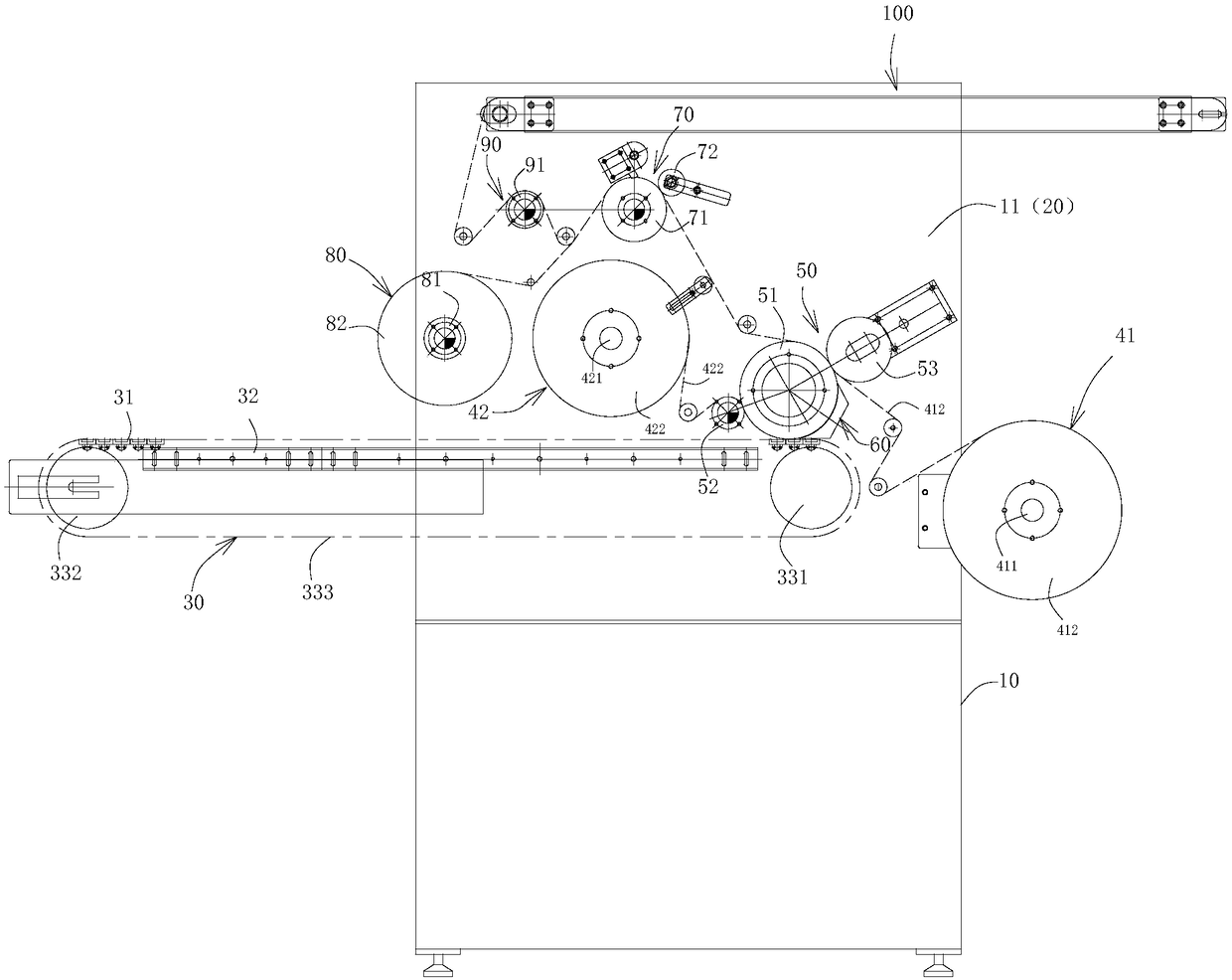

[0036] refer to figure 1, a double row packaging machine for packaging plastic spoons, comprising a frame 10, a drive motor 20, a feeding mechanism 30, a film roll mechanism 40, a heat sealing mechanism 50, a shovel turning mechanism 60, a cutting mechanism 70, and waste edge collection Roll mechanism 80, traction mechanism 90 and conveying mechanism 100.

[0037] The frame 10 is a structural frame made of section steel, and the bottom is provided with feet for fixing the packaging machine. The upper back of frame 10 is provided with cabinet 11, and drive motor 20 is installed in the cabinet 11, and drive motor 20 is connected with each mechanism through transmission mechanism, drives the motion of each mechanism.

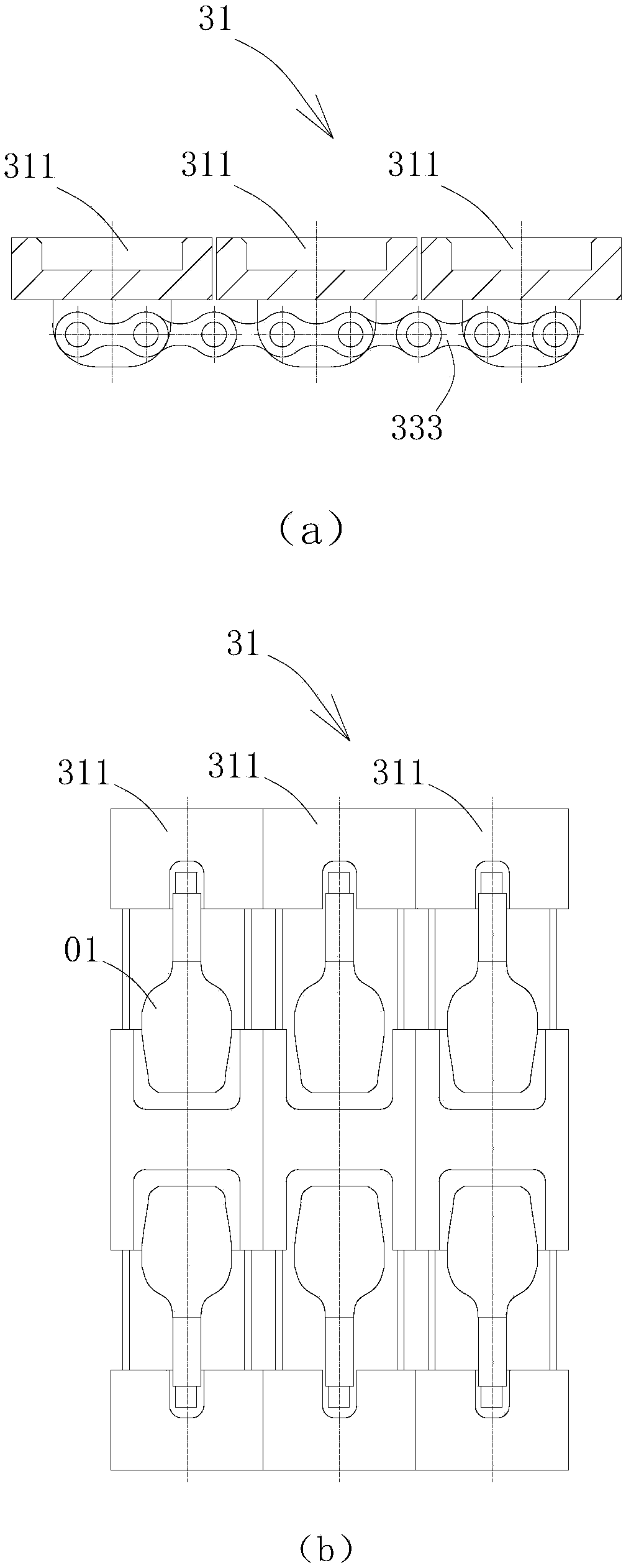

[0038] The discharging mechanism 30 is arranged at the front end of the frame, and includes a bracket mechanism 31 , a discharging trough 32 and a chain transmission mechanism 33 .

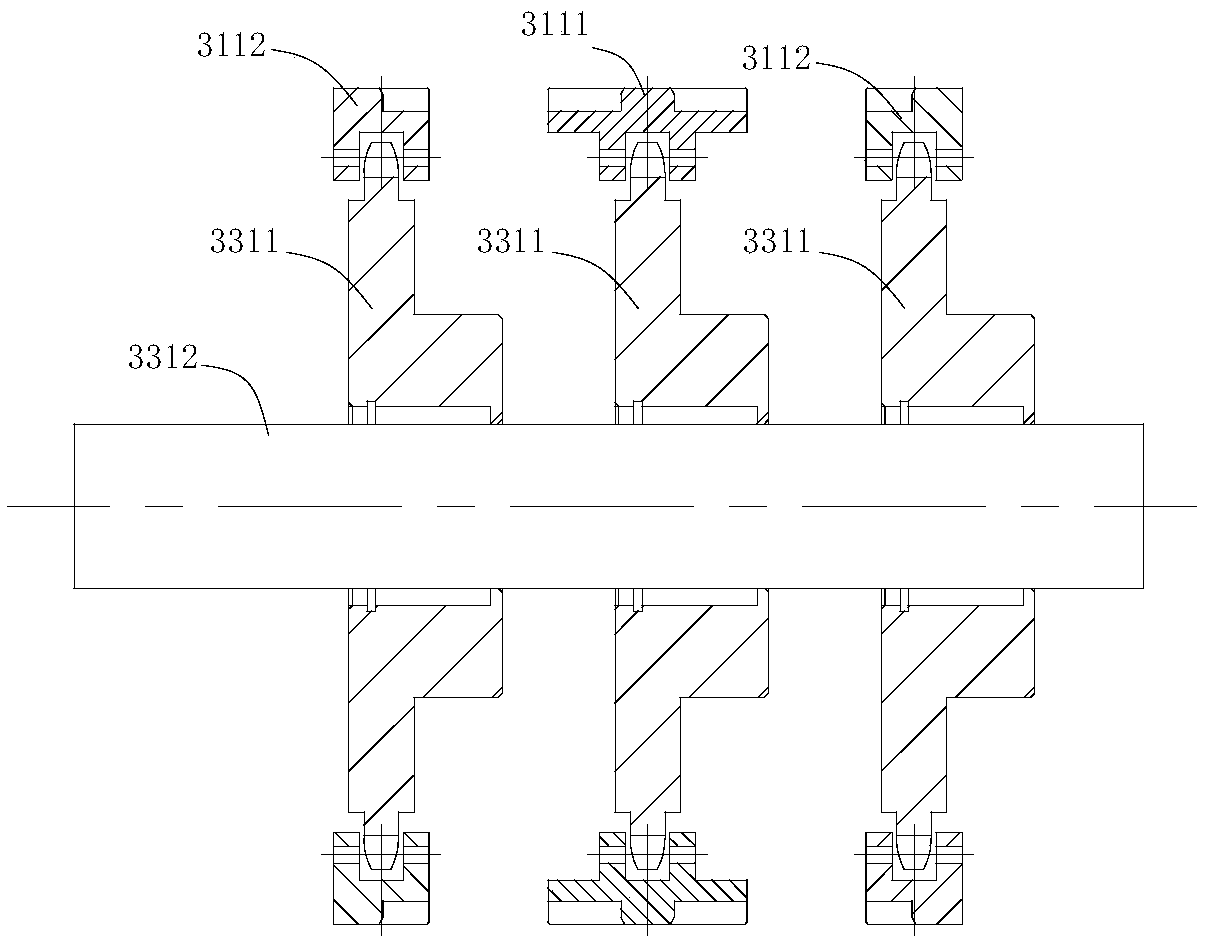

[0039] refer to figure 1 and figure 2 , the chain transmission mechanism 33 i...

Embodiment approach 2

[0050] Embodiment 2 is basically the same as Embodiment 1, and the only difference is that the packaging machine also includes a first proximity switch, a second proximity switch and a PLC control system, and the first proximity switch, the second proximity switch and the drive motor 20 are respectively Electrically connected with PLC. The first proximity switch is located at the front end of the discharge mechanism 30, fixed on one side of the frame 10, and the contact point is toward the bracket mechanism 31; the first proximity switch is prior art. The second proximity switch is located in the cabinet and near the drive shaft of the traction roller. The drive shaft of the traction roller is provided with a trigger mechanism that triggers the second proximity switch. The trigger mechanism can be a metal sheet or a metal rod. The traction roller drives the metal The sheet or metal rod makes a circular motion, and when the distance between the metal sheet or metal rod and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com