Preparation method of high-purity injection-grade terbutaline sulfate

A technology of terbutaline sulfate and sulfuric acid, which is applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve the problems of high-risk reagent environmental pollution risk and high cost, and achieve low cost, mild reaction, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

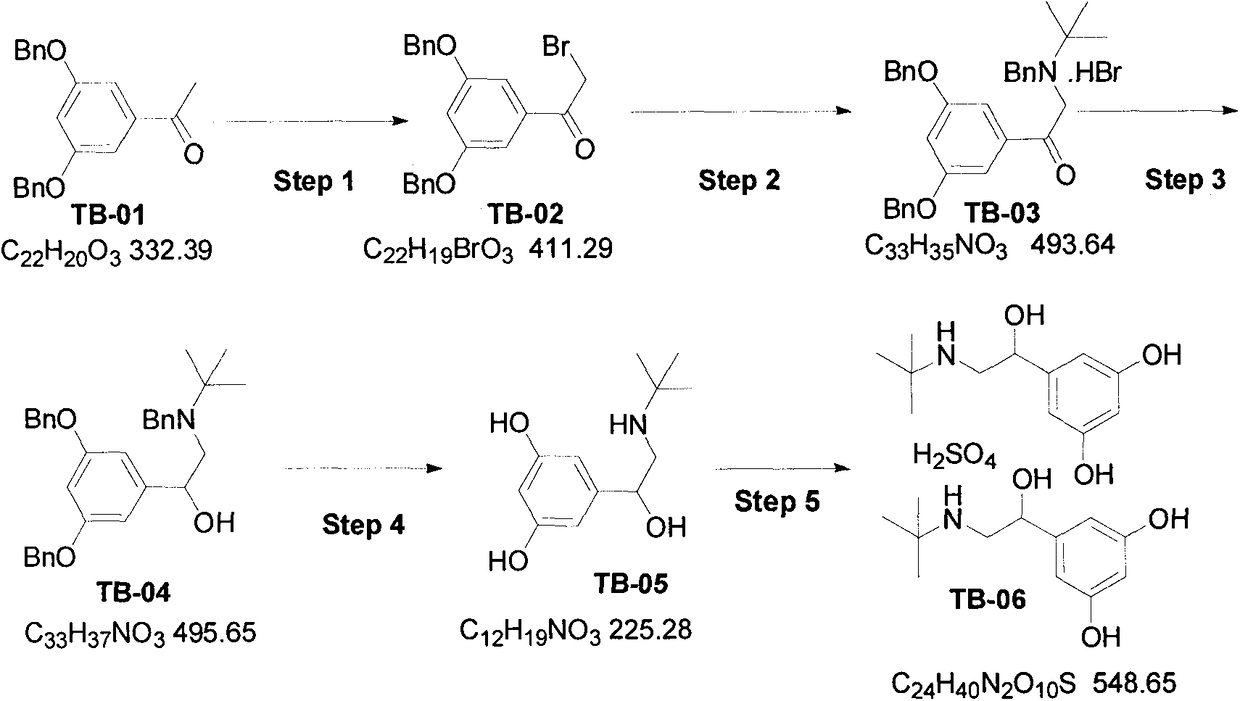

Method used

Image

Examples

Embodiment 1

[0018] Measure THF 10L, add EtOH 10L, stir and mix, add TB-01 1.66kg, cool to 0-10°C, add THF solution of TBATB (THF 8.8L, add TBATB 3.7kg, dissolve). 0 ~ 20 ℃ reaction 2h. Evaporate the solvent under reduced pressure, add 4L of ethanol and continue to replace the reaction solvent once under reduced pressure until the volume reaches 5L, add 10L of ethanol, stir and beat for 5h; drain, transfer the filter cake to a vacuum drying oven, and vacuum dry at 40°C for 10 hours to obtain White or off-white solid (TB-02) 1.69kg.

[0019] Add 5L of water to the reactor, stir, add TB-02, add 2.4kg of SM1, add 4.4L of ACN, heat to 60-90°C, count for 5 hours, stop heating, adjust the pH of the HBr solution to 1.0, add 10L of water, and stir Cool to 10-20°C, filter under reduced pressure, pump dry, stir and beat the filter cake with a mixed solvent of 8L of toluene and 8L of water for 4h; Vacuum dry at 45°C (vacuum degree is -0.085~-0.1Mpa) for 4 hours. Obtained TB-031.58kg.

[0020] Tak...

Embodiment 2

[0023] Measure THF 10L, add MeOH 10L, stir and mix, add TB-01 1.66kg, cool to 0-10°C, add THF solution of TBATB (THF9.2L, add TBATB 2.8kg, dissolve). 0 ~ 20 ℃ reaction 2h. Evaporate the solvent under reduced pressure, add 4L of ethanol and continue to replace the reaction solvent once under reduced pressure, until the volume is 4L, add 8L of ethanol, stir and beat for 4h; drain, transfer the filter cake to a vacuum drying oven, and vacuum dry at 40°C for 10 hours to obtain White or off-white solid (TB-02) 1.57kg

[0024] Add 4L of water to the reaction kettle, stir, add TB-02, add SM1 2.7kg, add ACN 4.1L, heat to 50-90°C, time for 4 hours, stop heating, adjust the pH of HBr solution to 0.9, add 10L of water, stir and cool to 10-20°C, filter under reduced pressure, pump dry, stir and beat the filter cake with a mixed solvent of 8L of toluene and 8L of water for 4h; Dry in vacuum at 45°C (vacuum degree is -0.085~-0.1Mpa) for 4 hours. Obtained TB-031.46kg.

[0025] Take THF 8...

Embodiment 3

[0028]Measure THF 10L, add MeOH 8L, stir and mix, add TB-01 1.66kg, cool to 0-10°C, add THF solution of TBATB (THF 9L, add TBATB 2.9kg, dissolve). 0 ~ 20 ℃ reaction 2h. Evaporate the solvent under reduced pressure, add 4L of ethanol and continue to replace the reaction solvent once under reduced pressure until the volume reaches 5L, add 10L of ethanol, stir and beat for 5h; drain, transfer the filter cake to a vacuum drying oven, and vacuum dry at 40°C for 10 hours to obtain White or off-white solid (TB-02) 1.71kg.

[0029] Add 5L of water to the reactor, stir, add TB-02, add 2.4kg of SM1, add 4.4L of ACN, heat to 60-90°C, count for 5 hours, stop heating, adjust the pH of the HBr solution to 1.0, add 10L of water, and stir Cool to 10-20°C, filter under reduced pressure, pump dry, stir and beat the filter cake with a mixed solvent of 8L of toluene and 8L of water for 4h; Vacuum dry at 45°C (vacuum degree is -0.085~-0.1Mpa) for 4 hours. Obtained TB-031.57kg.

[0030] Take TH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com