Integrated treatment system for composite waste gas comprising nitrogen oxides, chlorofluorocarbons, hydrochlorofluorocarbons, hydrofluorocarbons, and perfluorinated compounds

A technology of perfluorinated compounds and nitrogen oxides, which is applied in the fields of perfluorocarbon/hydrofluorocarbon capture, gas treatment, and greenhouse gas capture, and can solve problems such as high energy costs and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

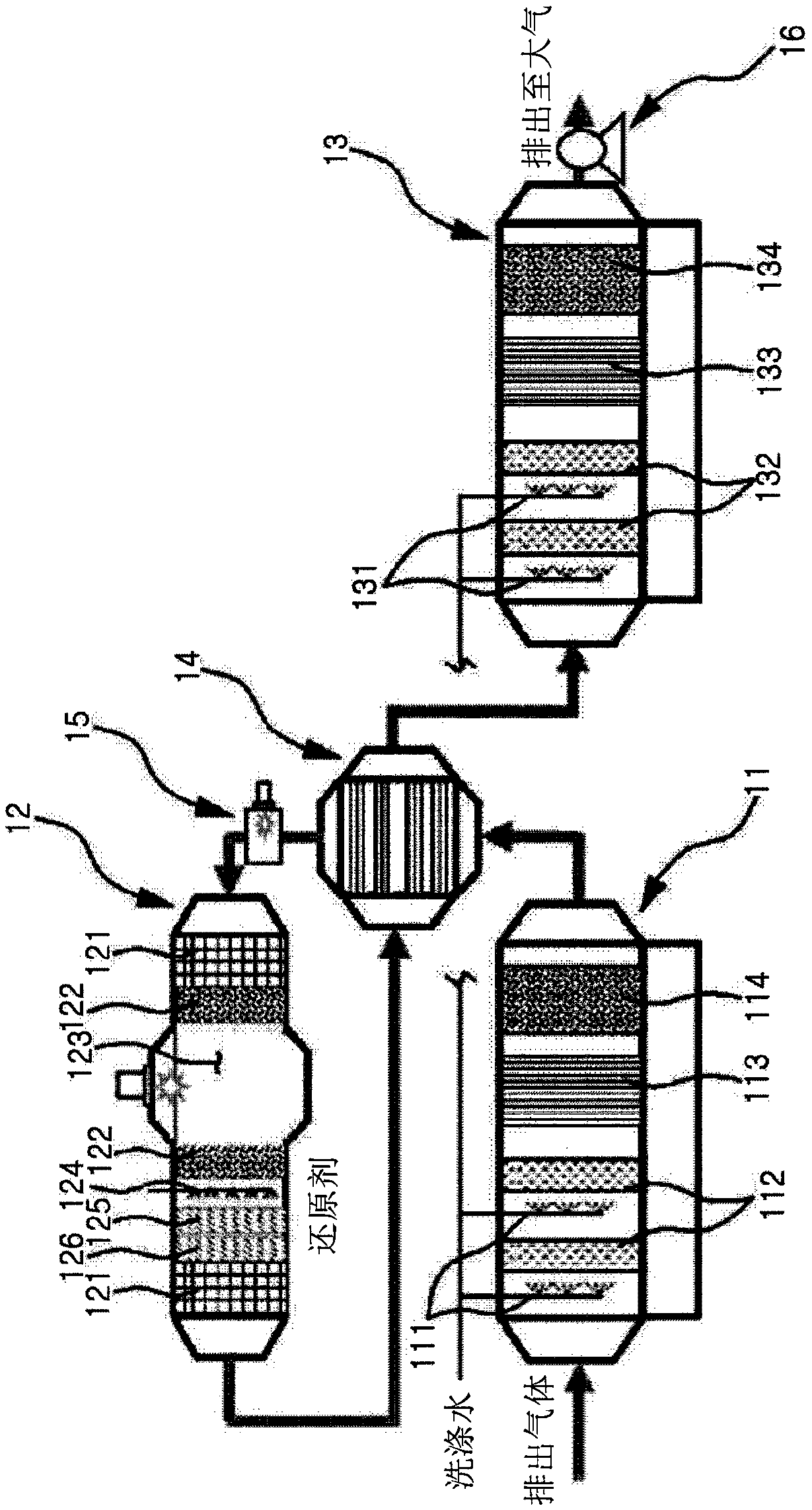

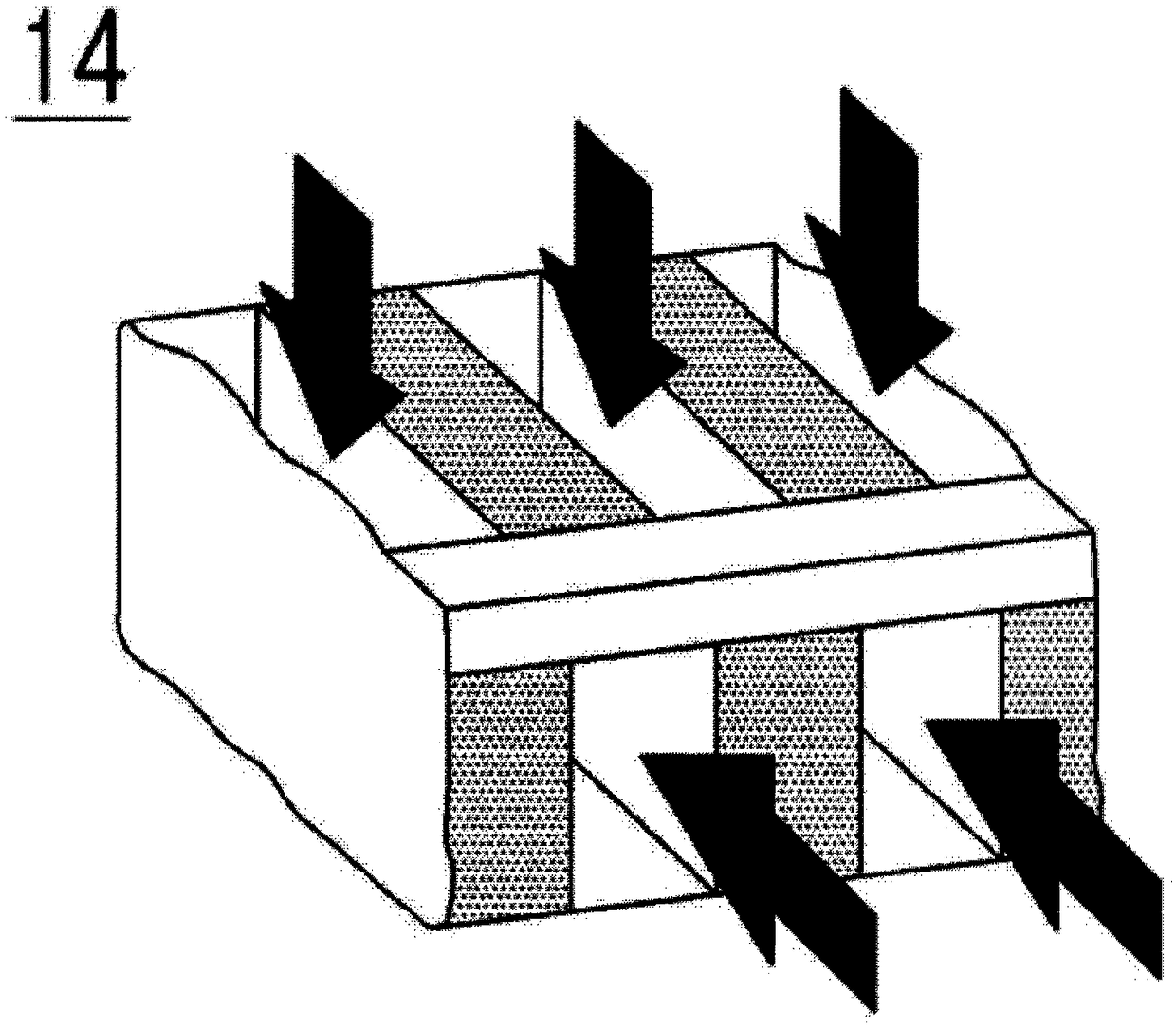

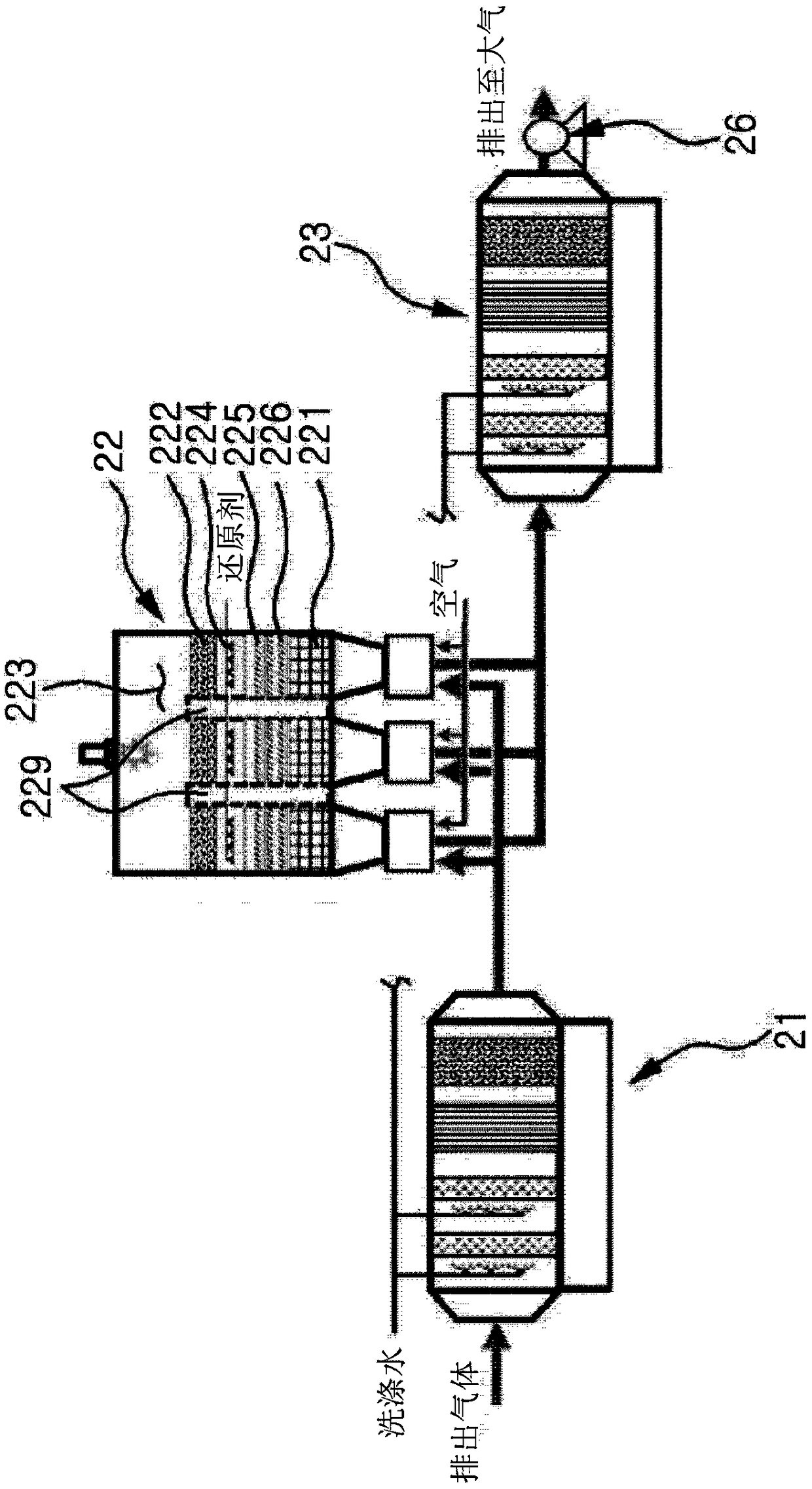

[0031] The system for integrated treatment of mixed exhaust gas of the present invention includes a first wet processor 11 , 21 or 31 , a decomposition reactor 12 , 22 or 32 and a second wet processor 13 , 23 or 33 . The system for integrally treating mixed exhaust gas of the present invention can be used for integrally treating the above-mentioned mixed exhaust gas, and can be implemented as first to third examples as described in detail below.

[0032] The first wet processor 11, 21 or 31 washes and adsorbs gas, SO x and dust including ash.

[0033] The decomposition reactor 12, 22 or 32 receives exhaust gas from the first wet processor 11, 21 or 31, and decomposes nitrogen oxides (NO x and N 2 O), CFCs, HCFCs, HFCs and PFCs.

[0034] The second wet processor 13, 23 or 33 receives the waste gas decomposed in the decomposition reactor 12, 22 or 32, and performs washing and adsorption treatment on it.

[0035] Each of the first wet processor 11, 21 or 31, the decomposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com