A multi-layered pipe and a method for forming a multi-layered pipe

A barrier layer and internal layer technology, applied in chemical instruments and methods, pipes/pipe joints/fittings, applications, etc., can solve problems such as poor connection, reduce production time, save storage space, and avoid oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

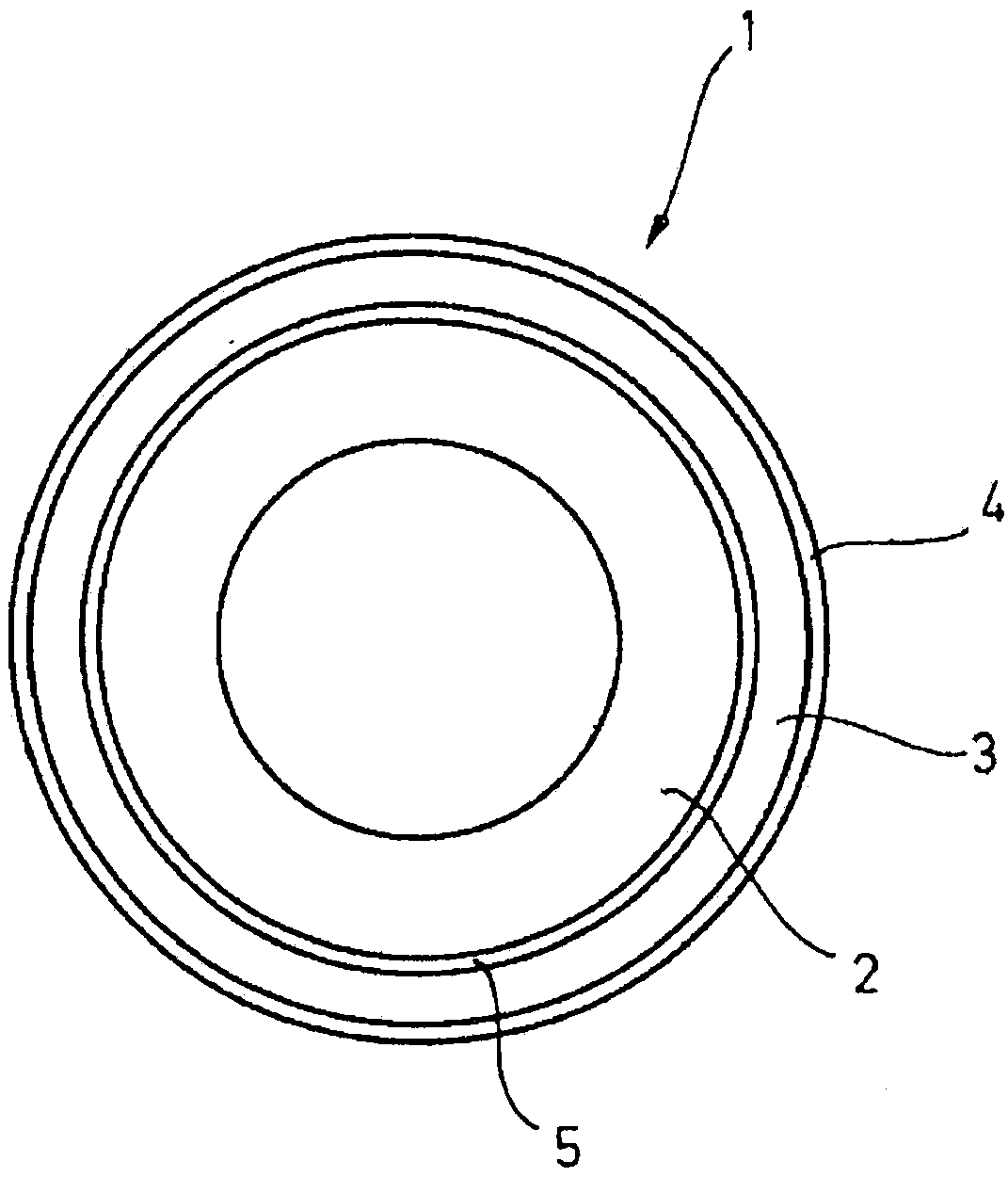

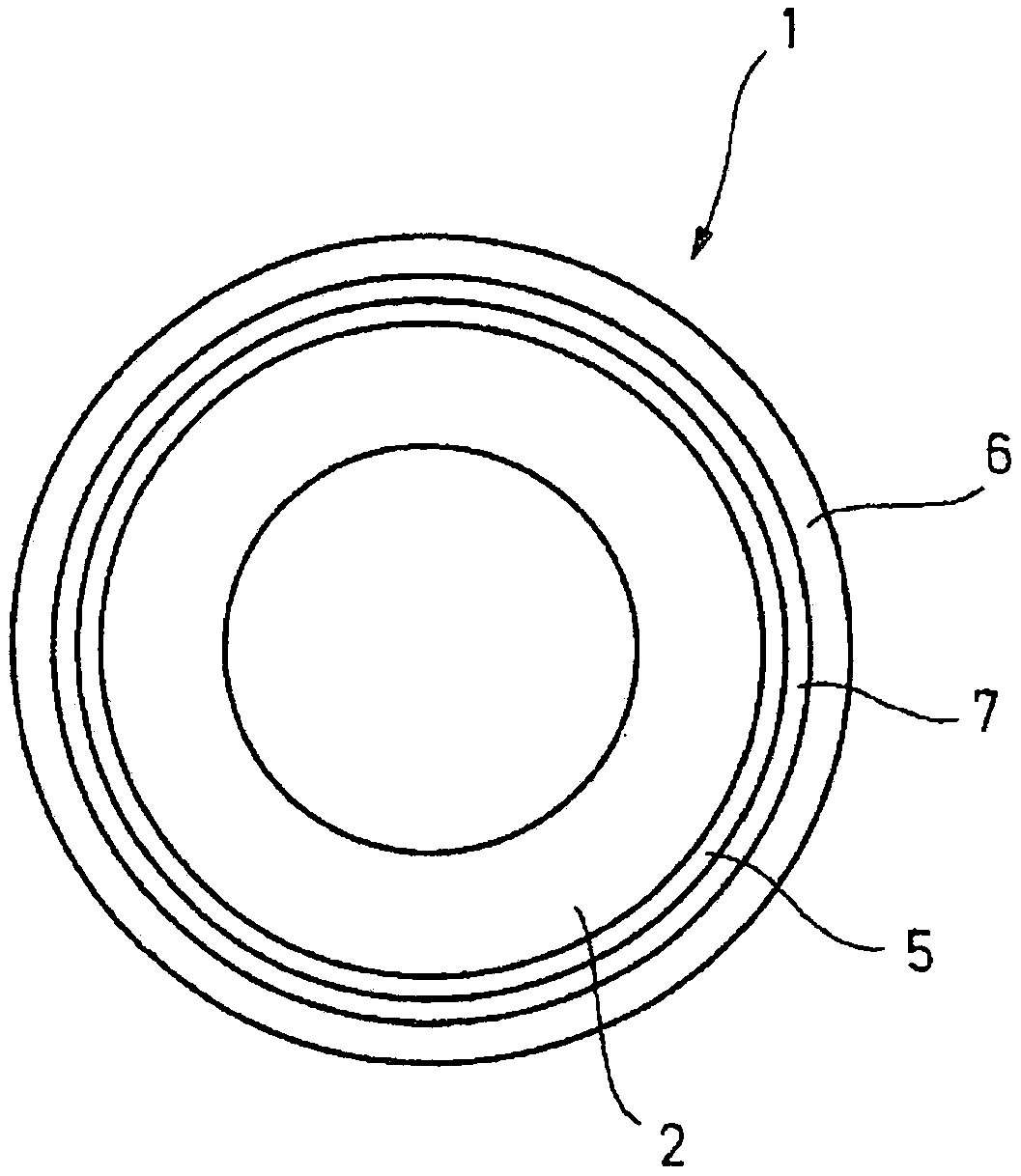

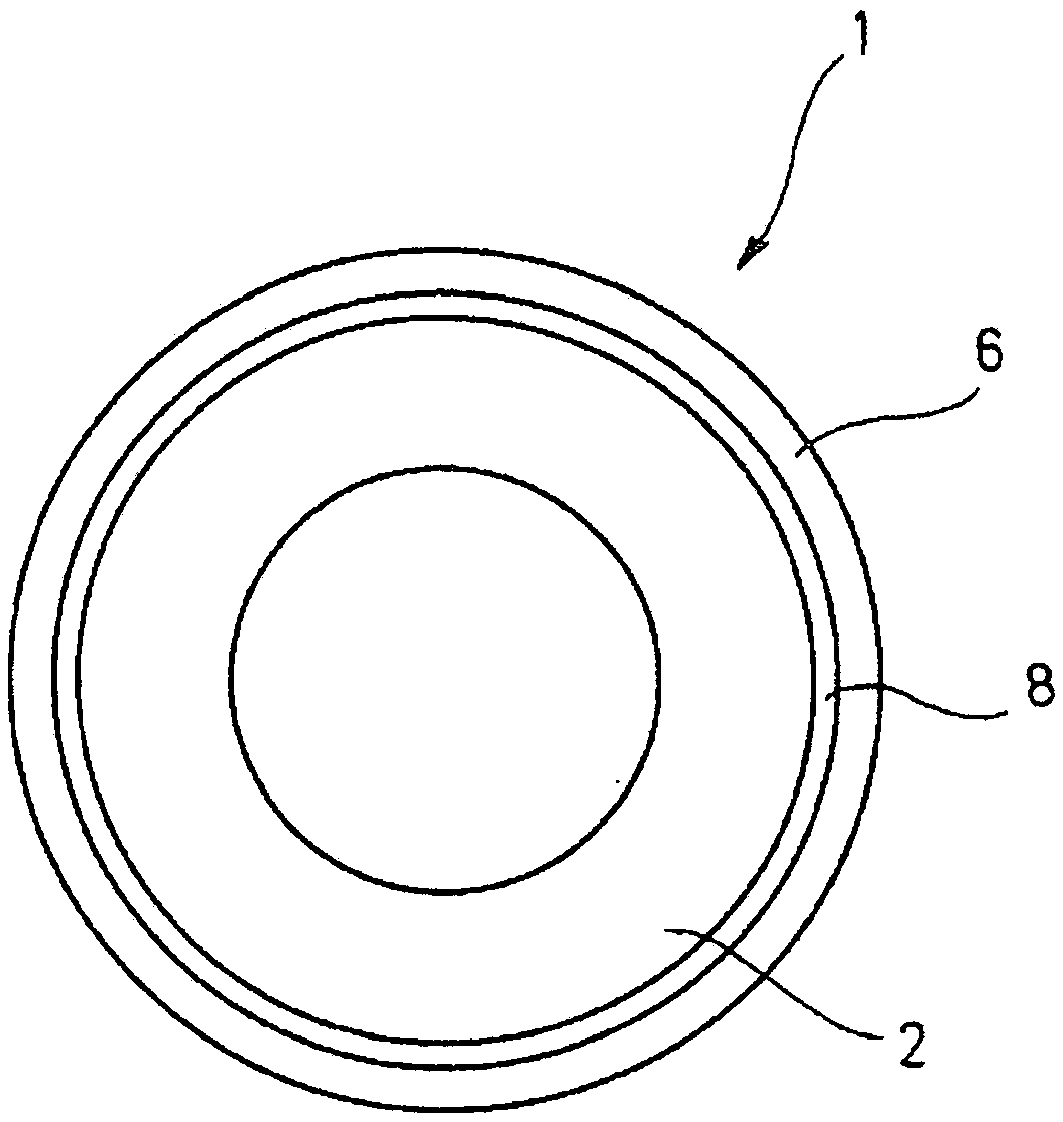

[0024] In the figures, the same components have the same reference numerals. figure 1 A cross-sectional view of a multilayer pipe 1 is schematically represented, comprising a wall with an inner layer 2 of polyolefin and a barrier layer 3 which is an outer layer relative to the layer 2 of polyolefin. The barrier layer 3 is formed of a non-metallic barrier material which has an increased resistance to the diffusion of hydrocarbon molecules through compared to polyolefins. Such hydrocarbon molecules may include relatively small hydrocarbon molecules, and more particularly may include toluenetrichloroethylene and p-dichlorobenzene. The pipe 1 also comprises a protective layer 4 which is an outer layer 5 with respect to the barrier layer 3 . The protective layer and the barrier layer can be combined together into a single layer. Preferably the protective layer and barrier layer are of the same material. Thus, no tie layers are required between these layers. These two layers can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com