Moisture-proof efflorescence prevention glass magnesium board and preparation method thereof

A glass magnesium board and anti-return technology, applied in the field of sheet materials, can solve the problem of high halogen return rate of glass magnesium board, and achieve the effects of increasing moisture resistance, fire resistance and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

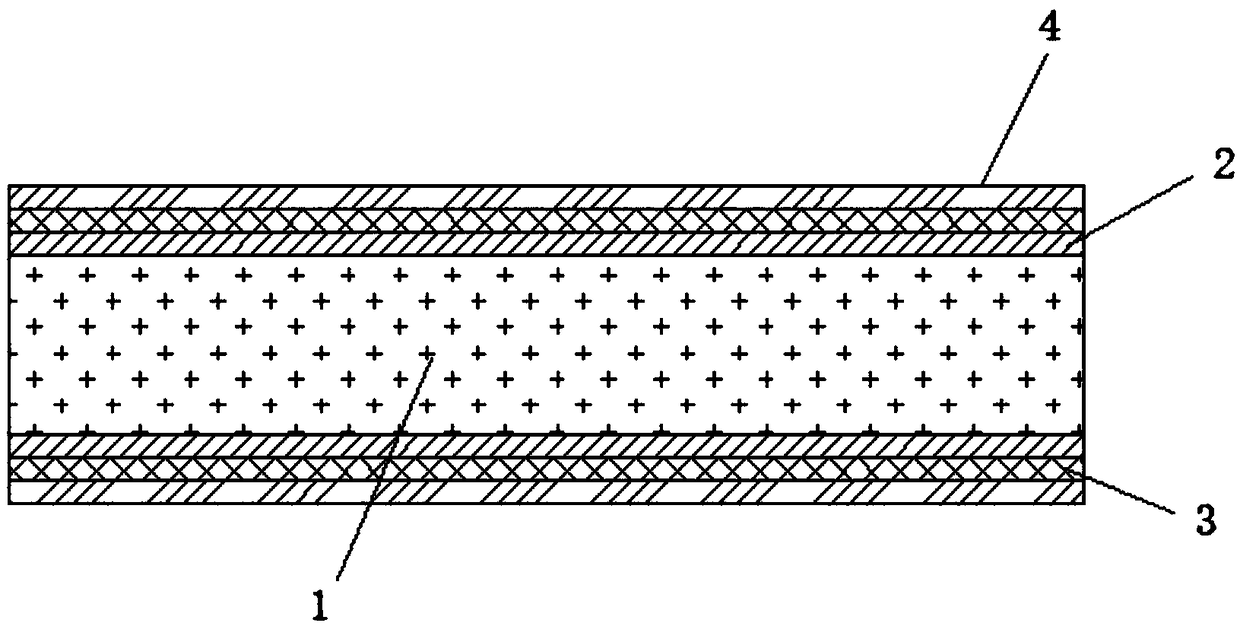

Image

Examples

Embodiment 1

[0021] The glass magnesium board body 1 is composed of the following raw materials in parts by weight: water: 30%, magnesium oxide: 6%, magnesium chloride: 15%, plant fiber: 8%, perlite: 10%, lithopone: 7%, polymer Polymer: 5%, Water Repellent: 4%, Wood Chips: 10%, Anti-reflux Agent: 3%.

[0022] The present invention also proposes a moisture-proof and anti-reflection halogenated glass magnesium board and a preparation method thereof, comprising the following steps:

[0023] Ingredients board

[0024] S1, first put magnesium chloride into the brine stirring tank, fully dissolve it with water, adjust to use Baume degree, and let it stand for about 24 hours for use (generally use between 20-26 Baume degree, according to climate, temperature, plate change, process Requirements and other appropriate adjustments), receive various raw materials according to the process formula requirements, and put various raw materials into the corresponding weighing hoppers;

[0025] S2, adjust ...

Embodiment 2

[0048] The glass magnesium board body 1 is composed of the following raw materials by weight: water: 31%, magnesium oxide: 4%, magnesium chloride: 15%, plant fiber: 7%, perlite: 8%, lithopone: 8%, polymer Polymer: 4%, Water Repellent: 6%, Wood Chips: 12%, Anti-reflux Agent: 5%.

[0049] The present invention also proposes a moisture-proof and anti-reflection halogenated glass magnesium board and a preparation method thereof, comprising the following steps:

[0050] Ingredients board

[0051] S1, first put magnesium chloride into the brine stirring tank, fully dissolve it with water, adjust to use Baume degree, and let it stand for about 24 hours for use (generally use between 20-26 Baume degree, according to climate, temperature, plate change, process Requirements and other appropriate adjustments), receive various raw materials according to the process formula requirements, and put various raw materials into the corresponding weighing hoppers;

[0052]S2, adjust the cutting...

Embodiment 3

[0075] The glass magnesium board body 1 is composed of the following raw materials in parts by weight: water: 28%, magnesium oxide: 5%, magnesium chloride: 16%, plant fiber: 8%, perlite: 11%, lithopone: 4%, polymer Polymer: 6%, Water Repellent: 6%, Wood Chips: 11%, Anti-reflux Agent: 5%.

[0076] The present invention also proposes a moisture-proof and anti-reflection halogenated glass magnesium board and a preparation method thereof, comprising the following steps:

[0077] Ingredients board

[0078] S1, first put magnesium chloride into the brine stirring tank, fully dissolve it with water, adjust to use Baume degree, and let it stand for about 24 hours for use (generally use between 20-26 Baume degree, according to climate, temperature, plate changes, process Requirements and other appropriate adjustments), receive various raw materials according to the process formula requirements, and put various raw materials into the corresponding weighing hoppers;

[0079] S2, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com