A kind of coagulation washing method of perfluorinated ethylene propylene resin

A technology of perfluoroethylene propylene and polyfluoroethylene propylene, which is applied in the field of polymers, can solve the problems of incomplete coagulation and precipitation of polyfluoroethylene propylene resin, waste of polyfluoroethylene propylene resin, unfavorable industrial production, etc., and achieves easy Washing removal, simple steps, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

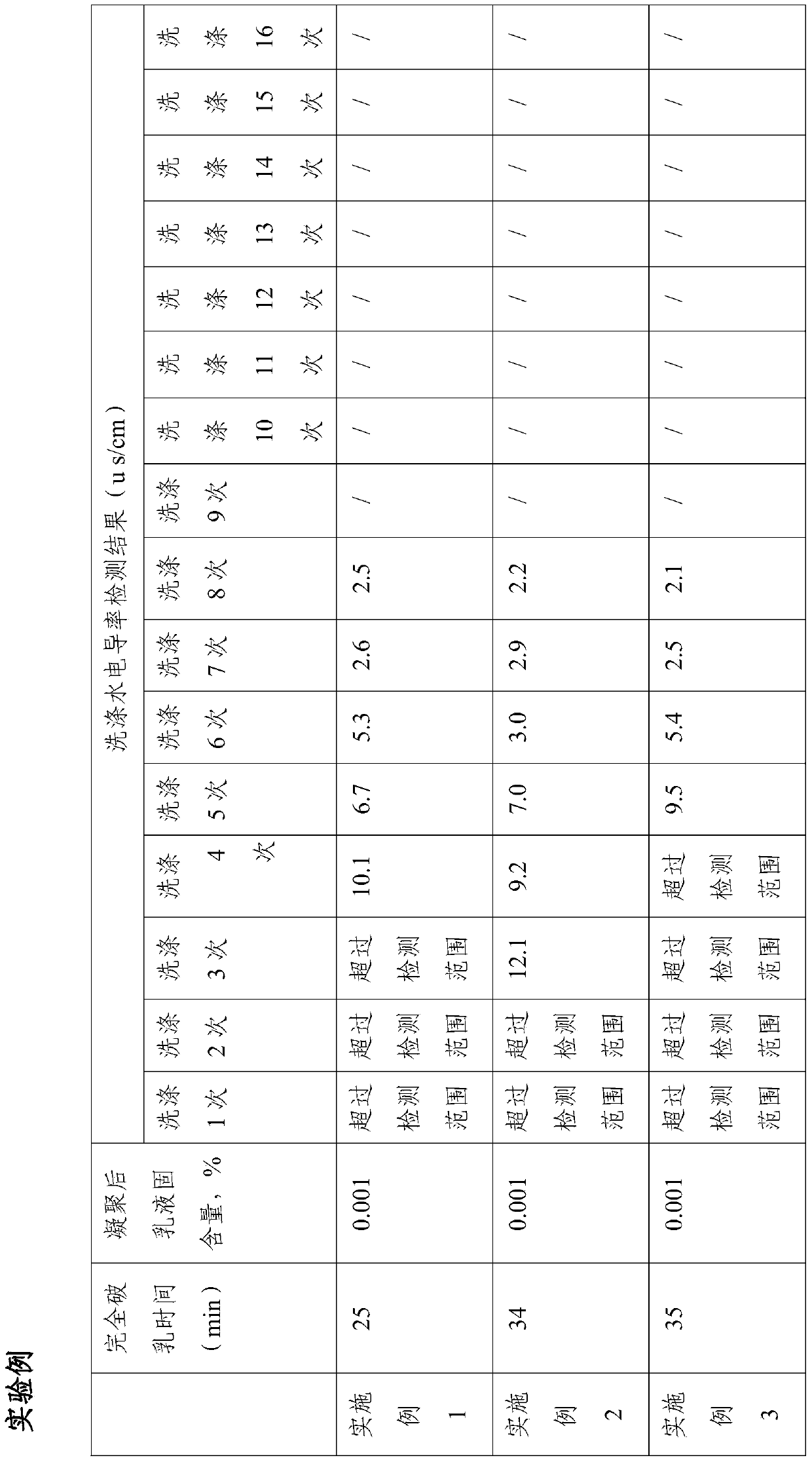

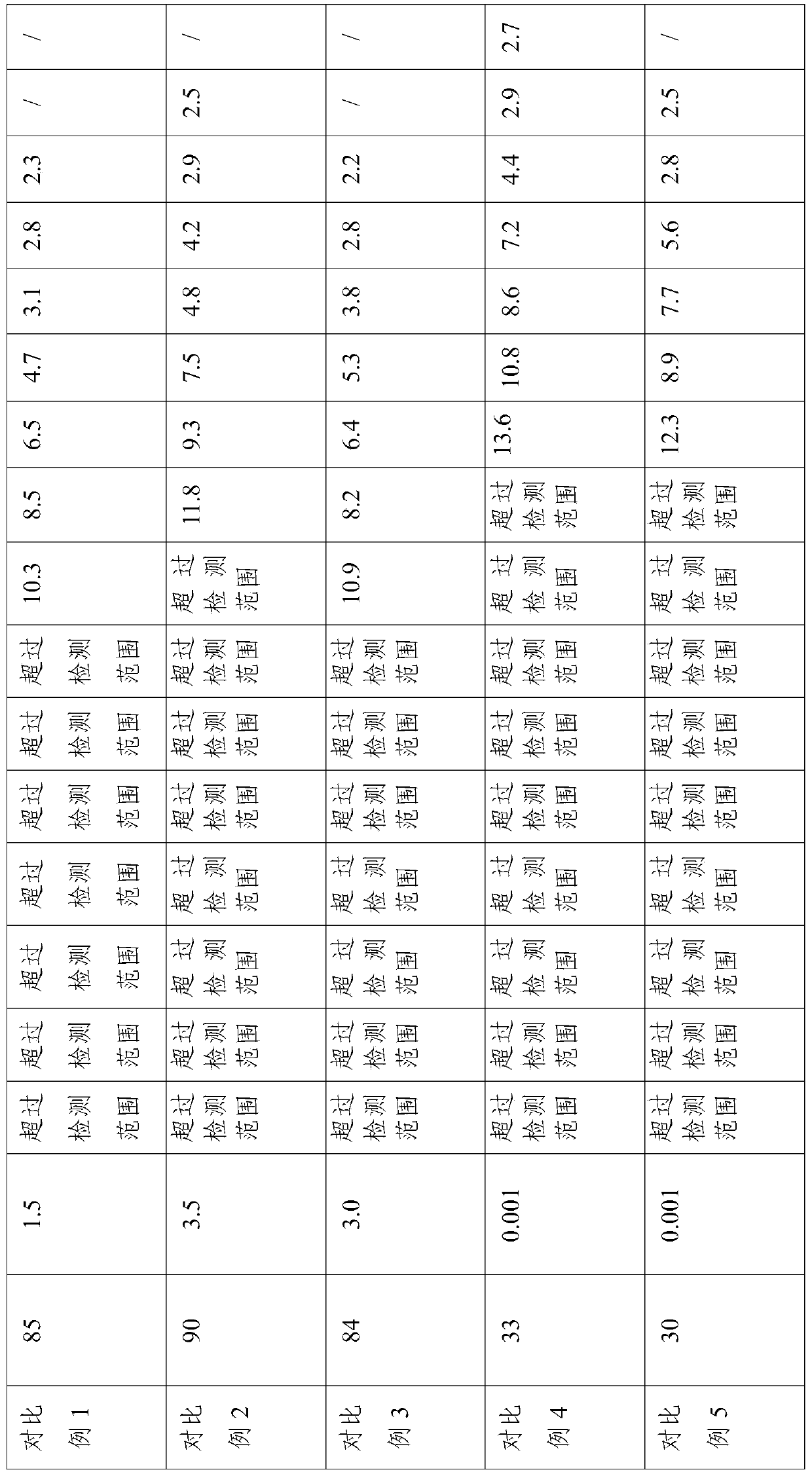

Embodiment 1

[0032] This embodiment relates to a preparation method of polyperfluoroethylene propylene resin, comprising the following steps:

[0033] 1) Add ion-free water at room temperature to the polyfluoroethylene propylene emulsion, adjust the specific gravity of the emulsion to 1.08, start stirring, and physically break the emulsion at 1200 rpm for 25 minutes;

[0034] 2) Add coagulant ammonium bicarbonate with a resin solid content of 2% to the above emulsion, and continue to stir at the same speed until the polyperfluoroethylene propylene emulsion is completely demulsified;

[0035] 3) Wash it several times with normal temperature deionized water with a volume ratio of 1 / 2 to 2 / 3 to the polyperfluoroethylene propylene precipitated from demulsification, until the conductivity of the washing water is lower than 3 us / cm after detection, That's it.

Embodiment 2

[0037] This embodiment relates to a preparation method of polyperfluoroethylene propylene resin, comprising the following steps:

[0038] 1) Add ion-free water at room temperature to the polyfluoroethylene propylene emulsion, adjust the specific gravity of the emulsion to 1.06, start stirring, and physically demulsify the emulsion at 1600 rpm for 23 minutes;

[0039] 2) Add coagulant ammonium bicarbonate with a resin solid content of 1.8% to the above emulsion, and continue to stir at the same speed until the polyperfluoroethylene propylene emulsion is completely demulsified;

[0040] 3) Wash it several times with normal temperature deionized water with a volume ratio of 1 / 2 to 2 / 3 to the polyperfluoroethylene propylene precipitated from demulsification, until the conductivity of the washing water is lower than 3 us / cm after detection, That's it.

Embodiment 3

[0042] This embodiment relates to a preparation method of polyperfluoroethylene propylene resin, comprising the following steps:

[0043] 1) Add ion-free water at room temperature to the polyfluoroethylene propylene emulsion, adjust the specific gravity of the emulsion to 1.09, start stirring, and physically break the emulsion at 1400 rpm for 25 minutes;

[0044] 2) Add coagulant ammonium bicarbonate with a resin solid content of 1.5% to the above emulsion, and continue to stir at the same speed until the polyperfluoroethylene propylene emulsion is completely demulsified;

[0045] 3) Wash it several times with normal temperature deionized water with a volume ratio of 1 / 2 to 2 / 3 to the polyperfluoroethylene propylene precipitated from demulsification, until the conductivity of the washing water is lower than 3 us / cm after detection, That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com