Polyurethane medical fixing pad material with low heat and low odor and preparation method thereof

A polyurethane, low-odor technology, applied in the field of polyurethane applications, can solve the problems of scalding the patient's skin, irritating the patient's skin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

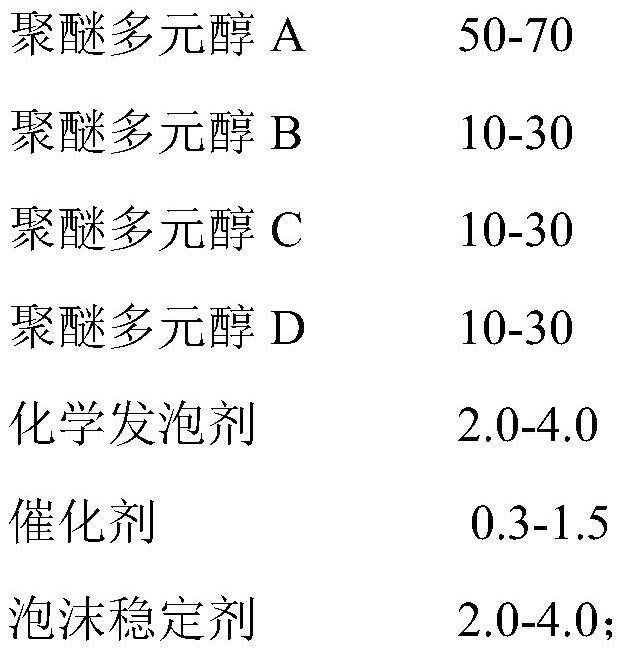

[0027] A component composition:

[0028] R6205 50 R8336 10 R6332 10 C310 30 water 3.1 Y-12 0.1 Y-27 0.1 A33 0.6 H3565 2.0

[0029] When preparing component A, put the raw materials in component A into the stirring tank at the above ratio, and stir evenly to obtain component A. Mix component A and component B at a ratio of 1:1.0, and react to obtain a polyurethane medical fixing pad material. The specific indicators are as follows:

[0030] Fixed pad forming time min 8.0 Fixed core density kg / m 3

Embodiment 2

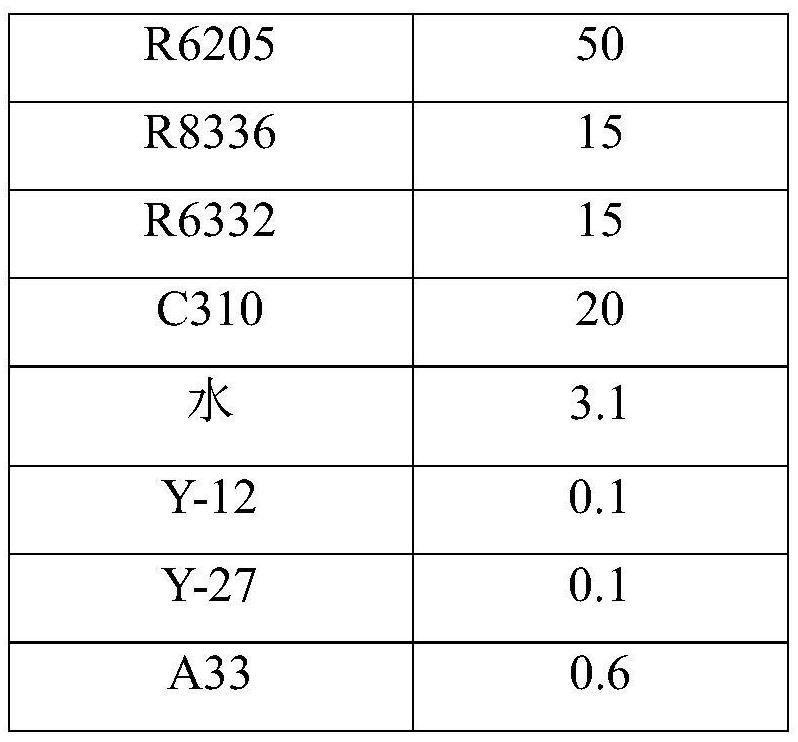

[0032] A component composition:

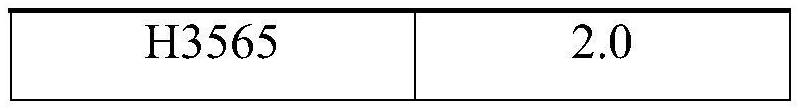

[0033]

[0034]

[0035] When preparing component A, put the raw materials in component A into the stirring tank at the above ratio, and stir evenly to obtain component A. Mix component A and component B at a ratio of 1:1.0, and react to obtain a polyurethane medical fixing pad material. The specific indicators are as follows:

[0036] Fixed pad forming time min 7.8 Fixed core density kg / m 3

Embodiment 3

[0038] A component composition:

[0039] R6205 70 R8336 10 R6332 10 C310 10 water 3.1 Y-12 0.1 Y-27 0.1 A33 0.6 H3565 2.0

[0040] When preparing component A, put the raw materials in component A into the stirring tank at the above ratio, and stir evenly to obtain component A. Mix component A and component B at a ratio of 1:1.0, and react to obtain a polyurethane medical fixing pad material. The specific indicators are as follows:

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com