Low-steel-grade pipeline clean steel and smelting process

A technology of clean steel and steel grade, applied in the field of metallurgy, can solve the problems of unqualified ultrasonic flaw detection of welding cracks, reduce the mechanical properties of steel plates, etc., and achieve the effect of reducing center segregation, reducing gas content, and preventing the formation of MnS inclusions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

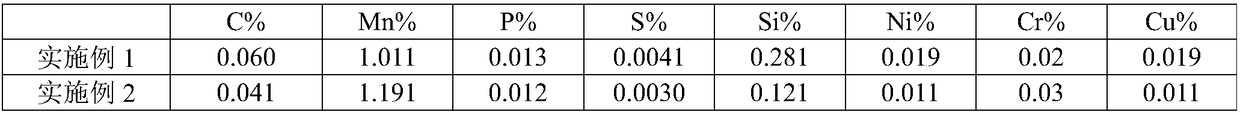

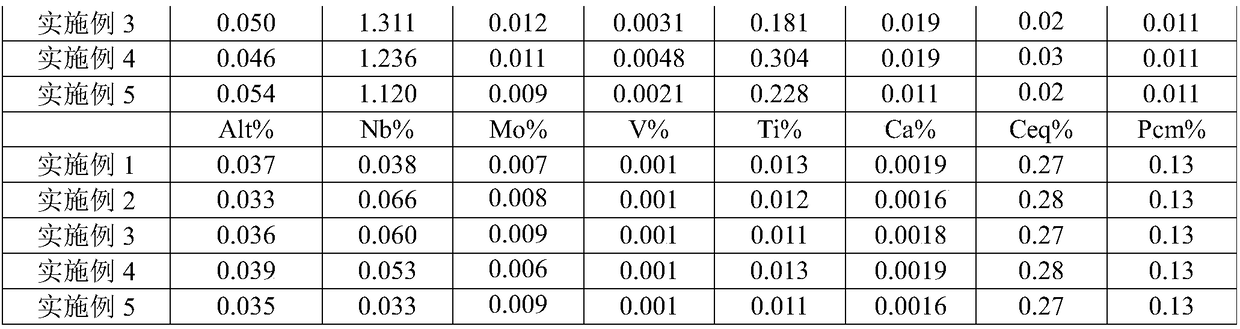

[0031] The invention provides a low-grade pipeline clean steel, the chemical composition and mass percentage of which are as follows: C: 0.04% to 0.07%, Si: 0.10% to 0.35%, Mn: 1.00% to 1.50%, P≤0.015%, S :0.0020%~0.0050%, Nb:0.030%~0.070%, Ti:0.006%~0.020%, Ni≤0.30%, Cr≤0.30%, Cu≤0.30%, Al:0.015%~0.050%, the balance is Fe and impurities.

[0032] The smelting process includes the following processes:

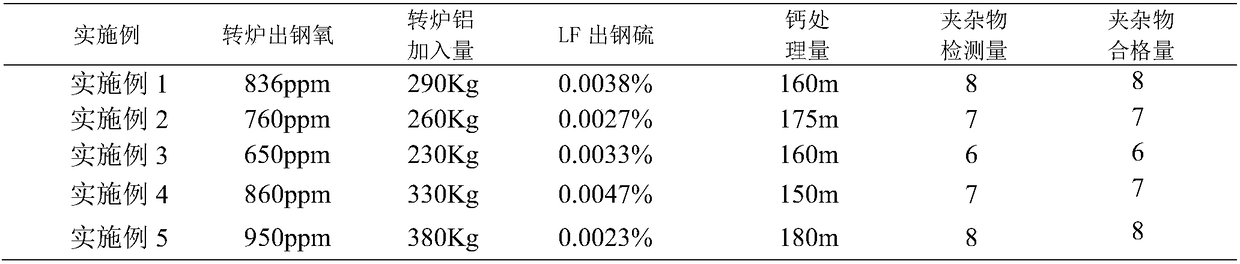

[0033] S1. The desulfurization station adopts the mixed injection method of liquid calcium oxide and magnesium powder for desulfurization. After desulfurization, deep slag removal treatment is carried out. The desulfurization standard of the desulfurization station is ≤0.005%. Tapping and adding aluminum blocks for strong deoxidation, the addition amount is 35kg / 100ppm, to prepare for LF desulfurization;

[0034] S2 and LF are mainly responsible for desulfurization and alloying, and the finished product sulfur is set at 0.002% to 0.005%;

[0035] S3, RH vacuum treatment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com