Vacuum grouting device and grouting method for prestress long distance, large diameter and multiple curvature duct

A long-distance, large-diameter technology, applied in construction, building construction, and building material processing, can solve the problems of long-distance, large-diameter, multi-curvature tunnel grouting, dense tunnel filling, and large voids, etc., to achieve Prevent the external harmful medium from invading the channel, the cross-section is completely dense, and the effect of improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

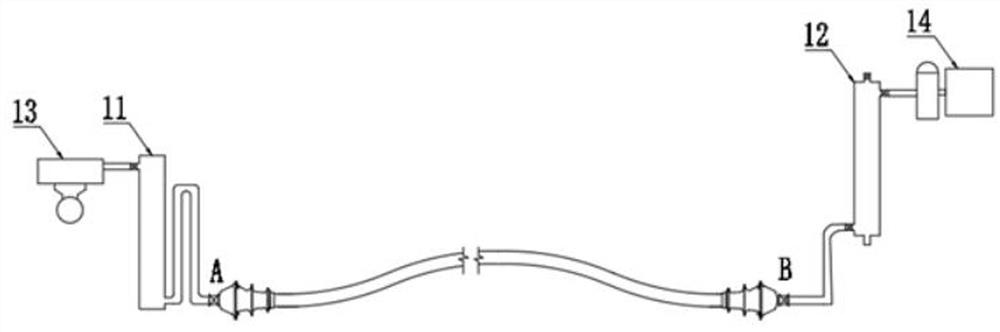

[0034] Such as Figure 1 ~ Figure 3 shown. The prestressed long-distance large-diameter multi-curvature hole vacuum grouting device of the present invention comprises a grout inlet buffer 11, a grout outlet buffer 12, a grouting pump 13 and a vacuum pump 14, and the grout inlet buffer 11 is connected to the grouting pump 14 and the Between the entrances A of the grouting tunnel, the grout outlet buffer 12 is connected between the outlet B of the tunnel to be grouted and the vacuum pump 14 .

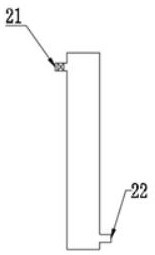

[0035] The slurry inlet buffer 11 is made of steel pipe, the upper and lower ends are sealed, the top side inlet 21 and the bottom side outlet 22 are welded by steel pipes, and a ball valve is installed at the top side inlet 21.

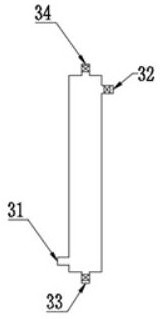

[0036] The slurry outlet buffer 12 is made of steel pipe, the upper and lower ends are sealed, the bottom side inlet 31, the top side outlet 32, the bottom sampling port 33 and the top exhaust port 34 are welded by steel pipes, and the top side outlet 32. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com