Mechanical fixing construction process of waterproof coiled material

A technology of waterproofing membrane and construction technology, which is applied in the direction of basic structure engineering, building insulation materials, and roofs using flexible materials, etc. It can solve the problem that the closure between the vapor barrier layer and the base layer is not good enough, affects the waterproof performance of the waterproofing membrane, and damages the waterproofing The waterproof performance of the coiled material and other issues can be improved to achieve the effect of improving the vapor barrier effect, improving the waterproof effect, and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

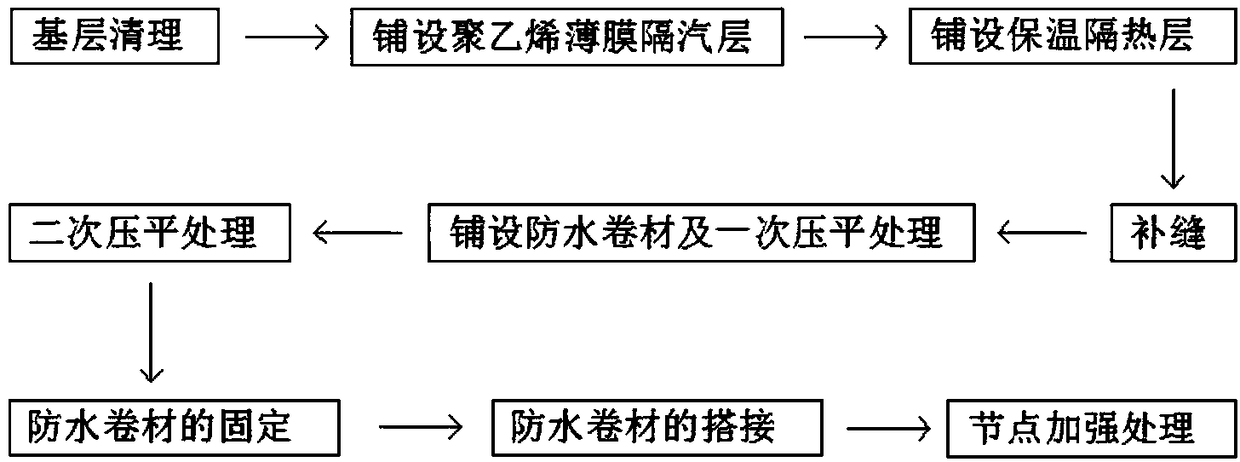

[0036] according to figure 1 Shown, the present invention proposes a kind of technical scheme:

[0037] The mechanical fixation construction process of waterproof membrane includes the following steps:

[0038] Step 1: Clean up the base

[0039] Clean and remove impurities on the surface of the built base, remove floating soil, oil stains and construction waste on the surface. For the part with accumulated water, it needs to be cleaned and discharged to ensure that the surface of the base is not covered by water and sundries. Use strong wind to dry the surface of the base. Carry out blowing and drying for 3 times to evaporate the water on the surface of the base layer and in the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com