A modular assembled copper-aluminum composite high-efficiency cooling and heating radiant panel unit and its manufacturing and installation method

A technology of copper-aluminum composite and radiation unit, which is applied in heating methods, lighting and heating equipment, space heating and ventilation, etc. It can solve the problems of low thermal conductivity of stainless steel, excessive waste of connecting screw rods, poor heat transfer efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

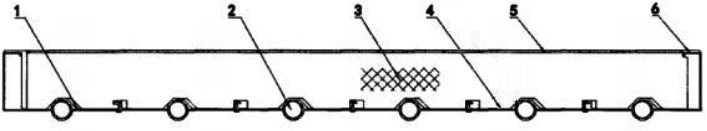

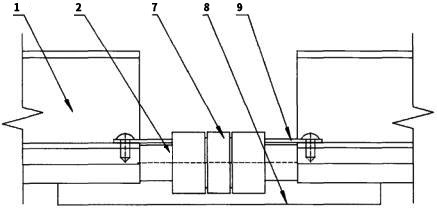

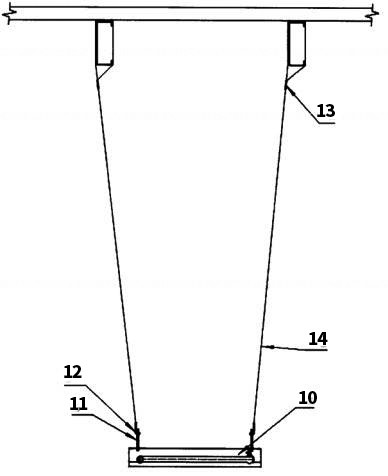

[0028] A modular assembled copper-aluminum composite high-efficiency cooling and heating radiant panel unit and its manufacturing and installation method, using aluminum alloy profiles as the radiant panel, according to the heating or cooling conditions, the inner wall pipe material is selected, the aluminum alloy heat conduction plate 1 and the heat conduction inner After the copper tube 2 is crimped by the equipment, the heat transfer and conduction surfaces are in close contact without gaps, and there is a thermal insulation material 3 on the back of the radiation unit to maintain unidirectional heat transfer or cooling radiation.

[0029] The cold radiation heat conduction plate of the radiant plate unit under cooling conditions is made of aluminum alloy profiles, and the surface is sprayed with low-reflectivity hydrophobic paint. The inner conduction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com