Modular assembly type copper aluminum composite efficient cooling and heating radiant panel unit and manufacturing and mounting method thereof

A radiation unit and copper-aluminum composite technology, which is applied in the field of copper-aluminum composite modular assembly copper-aluminum high-efficiency radiation unit device, can solve the problems of low thermal conductivity of stainless steel, many remaining waste materials of connecting screw rods, and poor heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

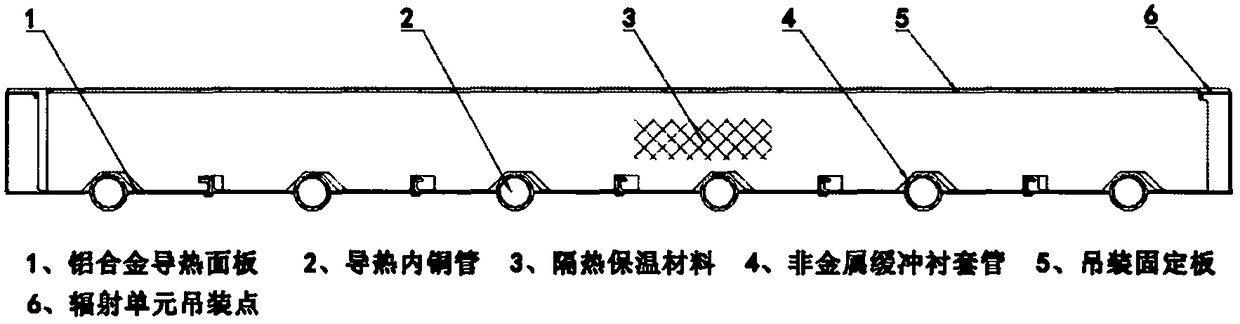

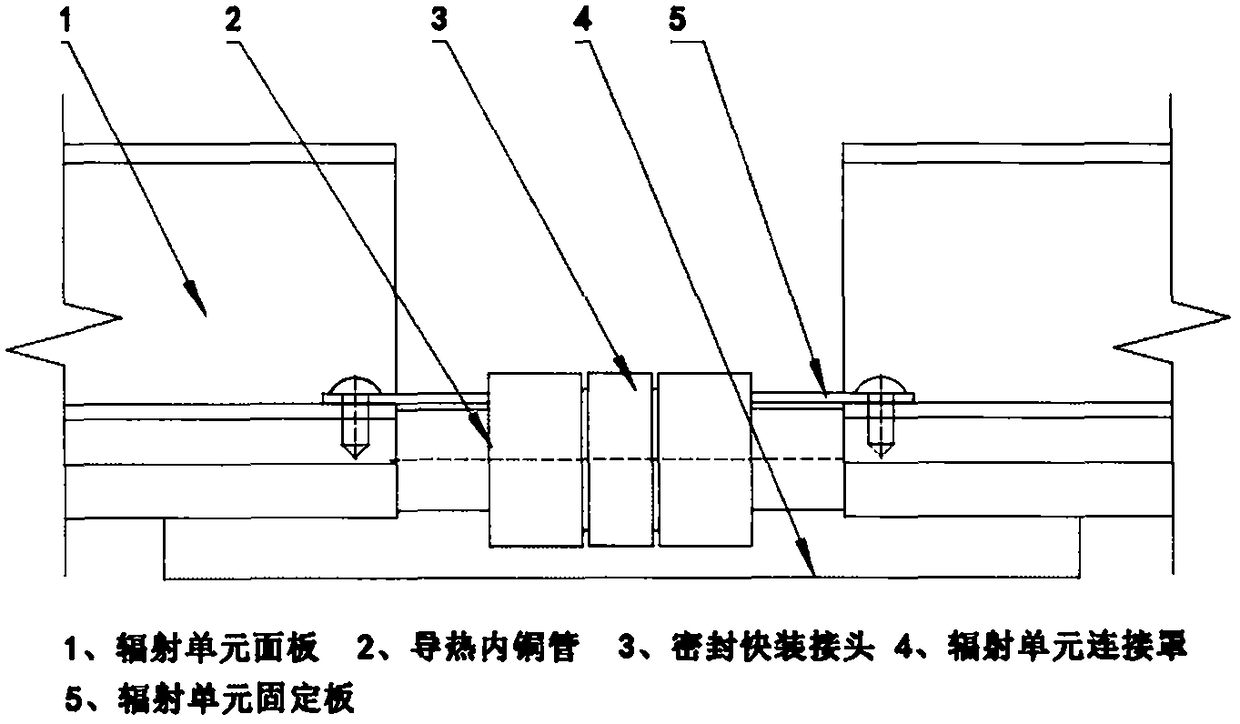

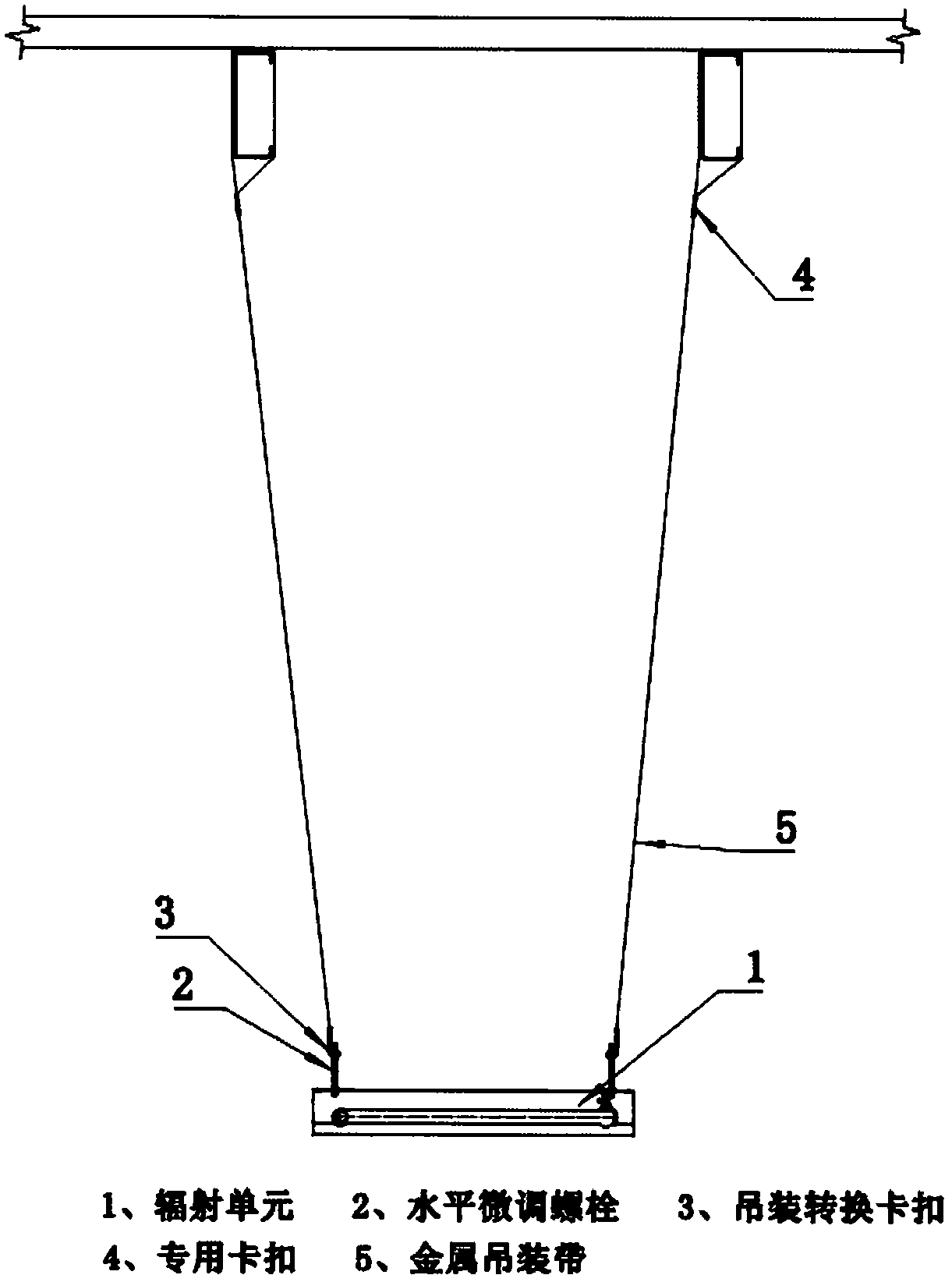

[0025] refer to figure 1 Described is a modular assembly type copper-aluminum composite radiant panel unit of the present invention. Its characteristics (1) use aluminum alloy profiles as the radiant panel, and use the inner wall pipe (2) according to the heating or cooling working conditions, and the radiant unit There is a thermal insulation material (3) on the back to maintain unidirectional heat exchange or cooling radiation.

[0026] figure 1 Cooling condition radiant plate unit cold radiant heat conduction plate (1) is made of aluminum alloy profile, the surface is sprayed with low reflectivity hydrophobic paint, the inner conduction pipe (2) is preferably non-metallic material buffer temperature control bushing material composite heat conduction pipe (4) On the surface, according to the different water inlet conditions, the material and wall thickness of the bushing (4) are different. After the heat conduction plate (1) and the heat conduction tube (2) are expanded and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com