Ventilating and air conditioning device

A technology of air-conditioning device and rotating device, which is applied in air-conditioning system, gas treatment, high-efficiency regulation technology and other directions, can solve the problems of hindered carbon dioxide adsorption performance, poor carbon dioxide separation performance, and can only be used in summer, so as to reduce the replacement of consumables. Cost, space saving, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

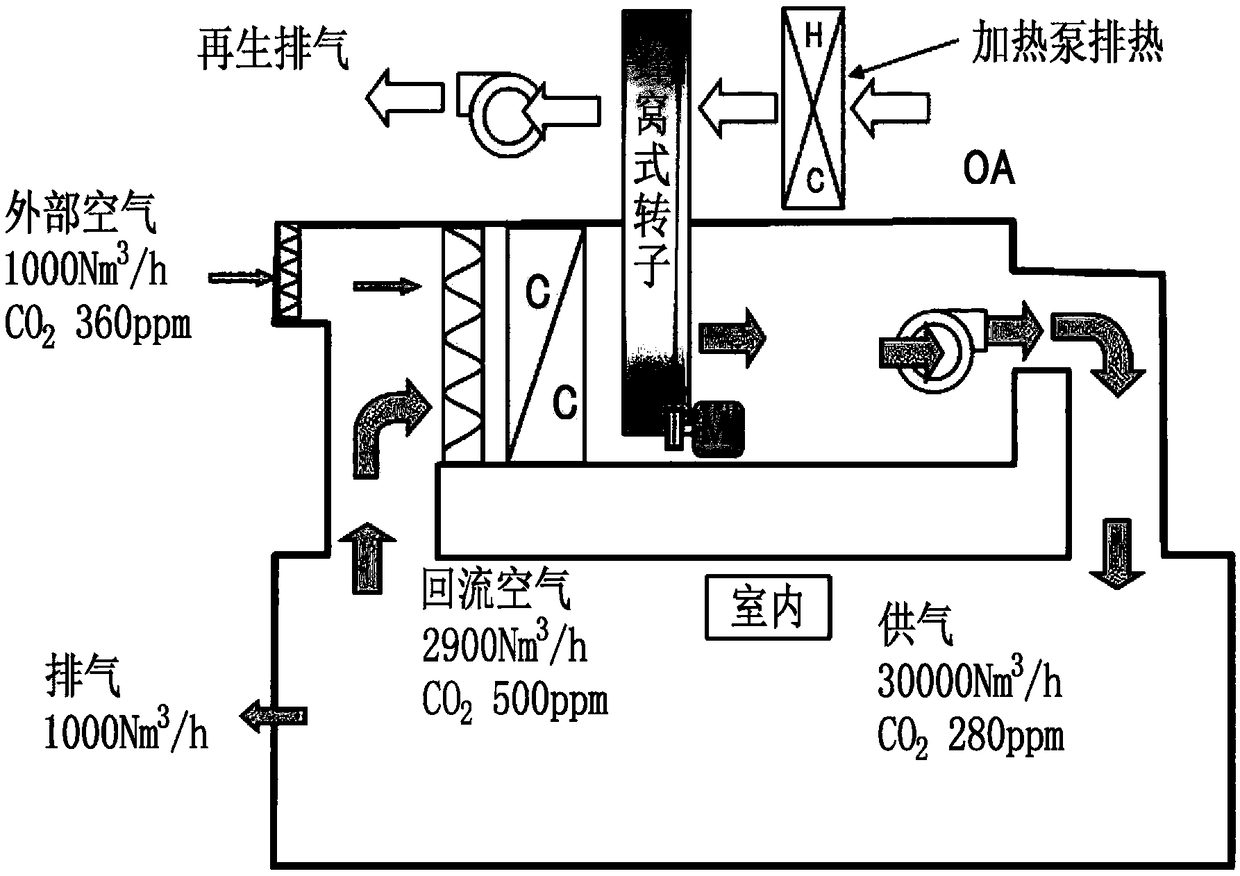

[0062] Below, according to image 3 Embodiments of the ventilating and air-conditioning apparatus of the present invention will be described in detail. 1 is a honeycomb rotor, which corrugates a porous sheet of inorganic fibers such as glass fibers to form a rotor-like honeycomb rotor, and carries the activity of an amine carbon dioxide absorbent added to absorb carbon dioxide. Carbon adsorption material.

[0063] The rotor is accommodated in a sealed casing divided into a treatment area and a desorption regeneration area, and the rotor is configured to be rotationally driven by a gear motor.

[0064]Introduce the treated air into the treatment area, absorb and remove pollutants such as carbon dioxide contained in the treated air, and supply purified air to the room. The process air may be return air or external air, and may be mixed according to the purpose. The rotor honeycomb that absorbs carbon dioxide or pollutants rotates and moves to the desorption regeneration area,...

Embodiment 2

[0067] The flow chart of embodiment 2 of the present invention is shown in Figure 4 . The structure of the device is the same as that of Example 1 image 3 almost the same. For the honeycomb rotor 1, 30 g / m2 porous paper containing plastic fibers mainly composed of inorganic fibers such as glass fibers is coated with fine particles of an amine ion exchange resin with a particle size distribution of 0.02 to 0.1 mm and an average particle size of 0.03 mm. Slurry liquid mixed with activated carbon particles and heat-resistant and water-resistant binder, the dried sheet ( Figure 13 ) was corrugated at a pitch of 3.0 mm and a height of 2.0 mm, and was wound into a rotor to obtain a honeycomb rotor 1 with a bulk density of 150 kg / m3 containing 50% by weight of amine ion exchange resin and fine particles of activated carbon .

[0068] In the present invention, since steam is used for the desorption of adsorbed carbon dioxide, it is not necessary to make the honeycomb rotor 1 in...

Embodiment 3

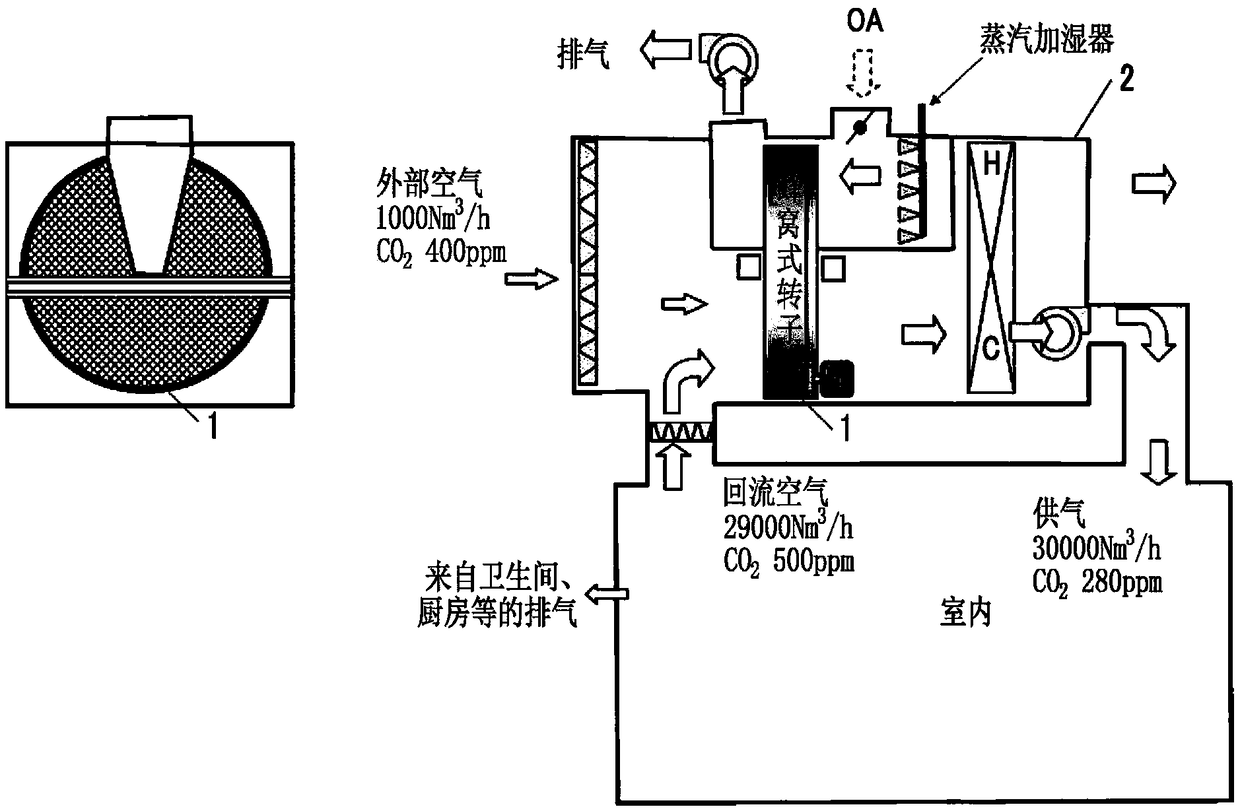

[0071] With regard to the honeycomb rotor, a porous paper of 35 g / m2 mainly composed of inorganic fibers such as glass fibers is corrugated at a pitch of 3.0 mm and a height of 2.0 mm, and it is wound and rotorized to obtain a honeycomb rotor that contains 70% by weight. A honeycomb rotor 1 with a volume density of 150 kg / m3 of carbon dioxide occlusion gel obtained by dip-coating and drying an amine-based polymer gel having carbon dioxide occlusion properties.

[0072] In terms of the structure of the device, it is roughly the same as Embodiment 2, but as Figure 5 In this way, the honeycomb rotor is fixed in the rotor adsorption device with the outer peripheral sealing structure, the process air is passed to the air conditioner, and the air that has passed through the device is returned to the room again. The device is characterized in that the adsorption device Sector-shaped funnels with seals rotating co-rotating around the rotor shaft are attached to the front and back of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com