Multi-station gas detector calibration instrument and calibration method of multi-station gas detectors

A gas detector and multi-station technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness and measuring the rate of increase and deceleration of fluid, etc. It can solve the problems of repeated work, low verification efficiency, and difficulty in meeting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

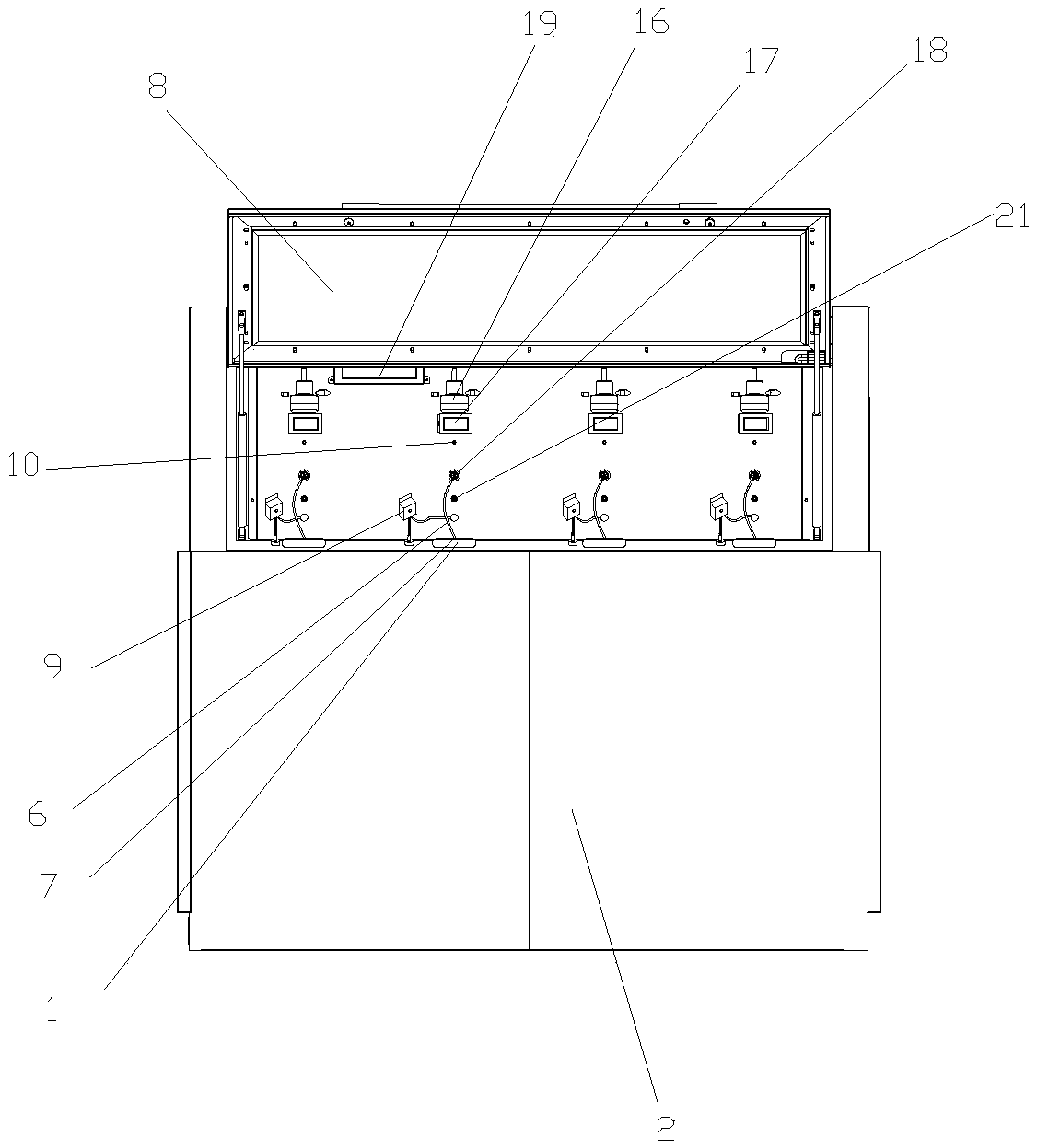

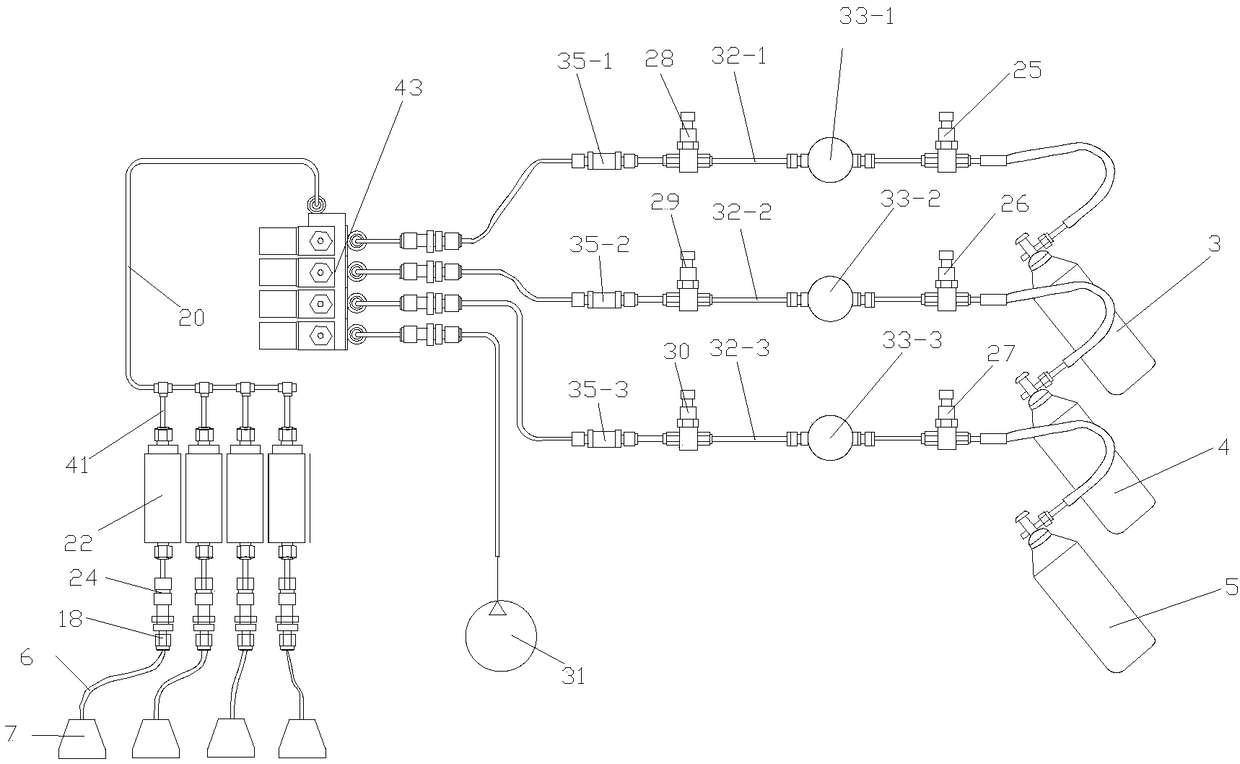

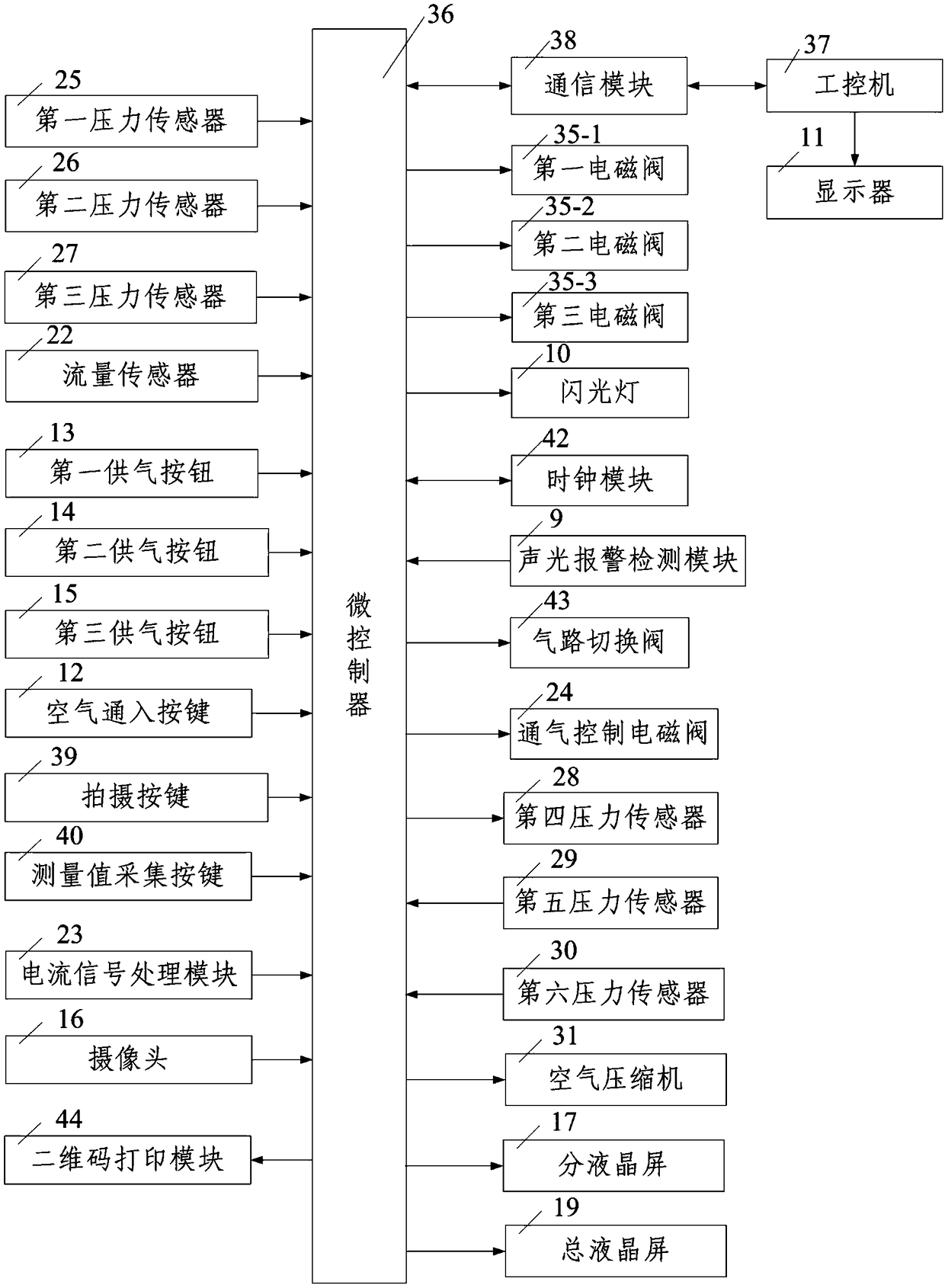

[0119] Such as Figure 1 to Figure 3 The shown multi-station gas detector verification instrument includes a frame 2, a verification station installed on the frame 2 and a plurality of gas detectors 1 for verification, and a plurality of gas detectors. 1. A gas supply device for supplying standard gas, and a monitoring device for monitoring the verification station and the gas supply device; the frame 2 is provided with a sealed door 8 that can be opened and closed, The number is multiple, and each of the verification stations is provided with a camera 16, a sub-LCD screen 17, a current input interface 21, a flashlight 10, an acousto-optic alarm detection module 9 and an air supply port 18, and the frame 2 is provided with There is a total liquid crystal screen 19, and the air supply port 18 is connected with the air pipe 6 and the air cover 7 connected with the air pipe 6 and covered on the gas detector 1; Port 18 provides the first gas supply mechanism, the second gas suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com