A cleaning system for viscose yarn

A treatment system and cleaning technology, applied in fiber treatment, recycling technology, decomposition of fiber-containing substances, etc., can solve the problems of reducing the production efficiency of viscose yarn and increasing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

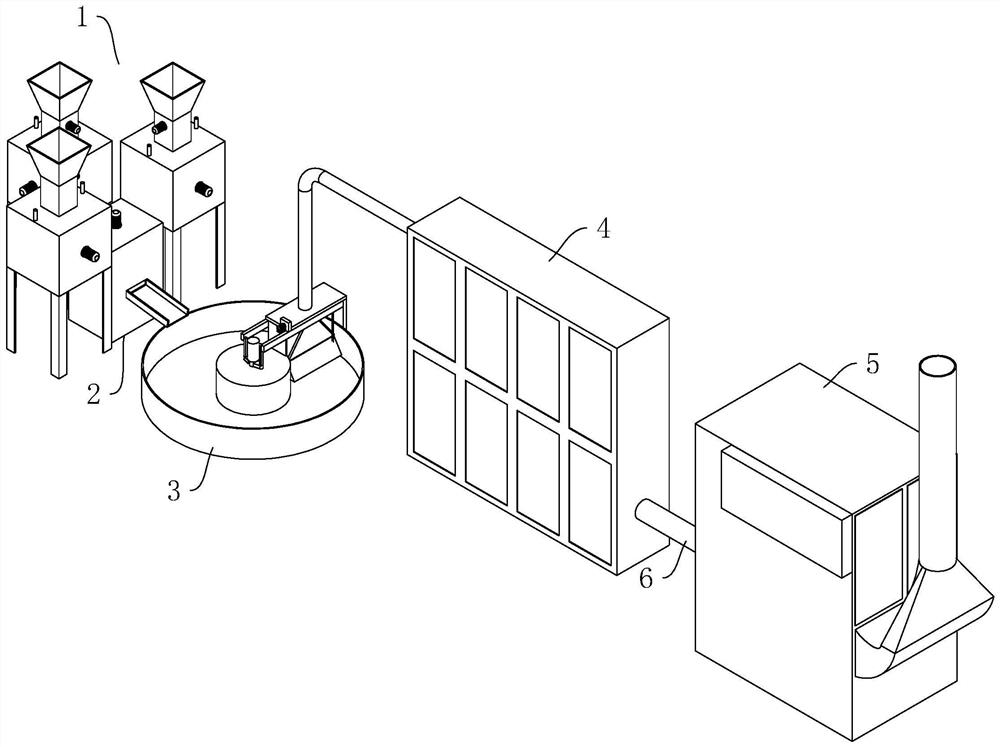

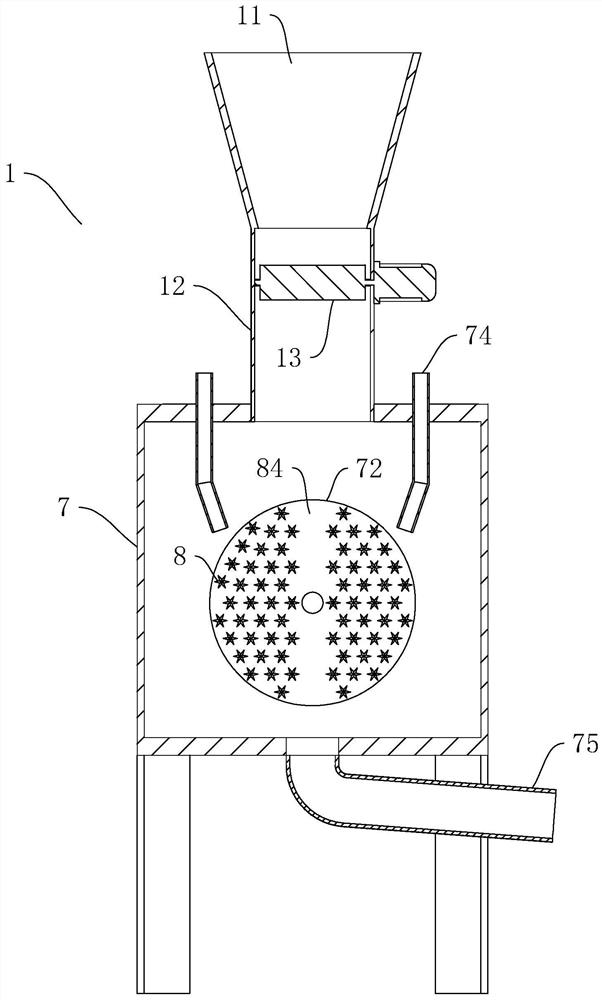

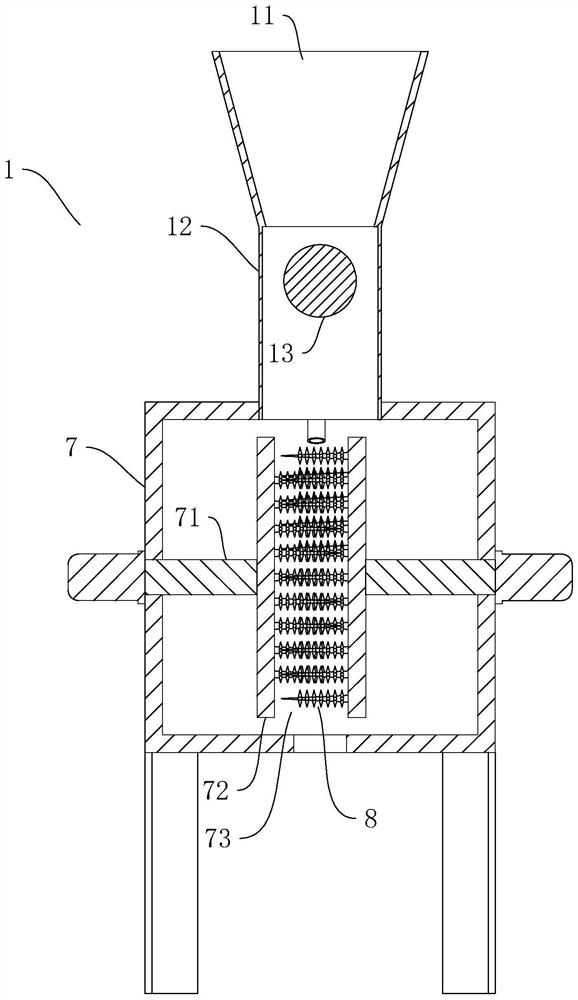

[0038] Such asfigure 1 As shown, a cleaning treatment system for viscose yarn includes a crushing device 1, a mixing device 2, a feeding device 3, a cleaning machine 4 and a cleaning machine 5 arranged in sequence, and the cleaning machine 4 and the cleaning machine 5 and the discharge end of the cleaning machine 5 are all provided with a transport air duct 6.

[0039] When the above-mentioned cleaning system is used to process the cotton chips, the cotton chips of different materials or colors are selected according to a certain ratio, and the cotton chips are placed in the crushing device 1, and the cotton chips are crushed by the crushing device 1. Then, after being mixed evenly by the mixing device 2, the crushed cotton block is transported to the impurity remover 4 by the feeding device 3, and the impurity in the cotton block is removed by the impurity r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com