Method preparation of digital printing ink based on boron nitride nanosheet modification

A digital printing and boron nitride technology, applied in the textile field, can solve the problems of poor high temperature resistance and poor ink stability, and achieve the effect of good stability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

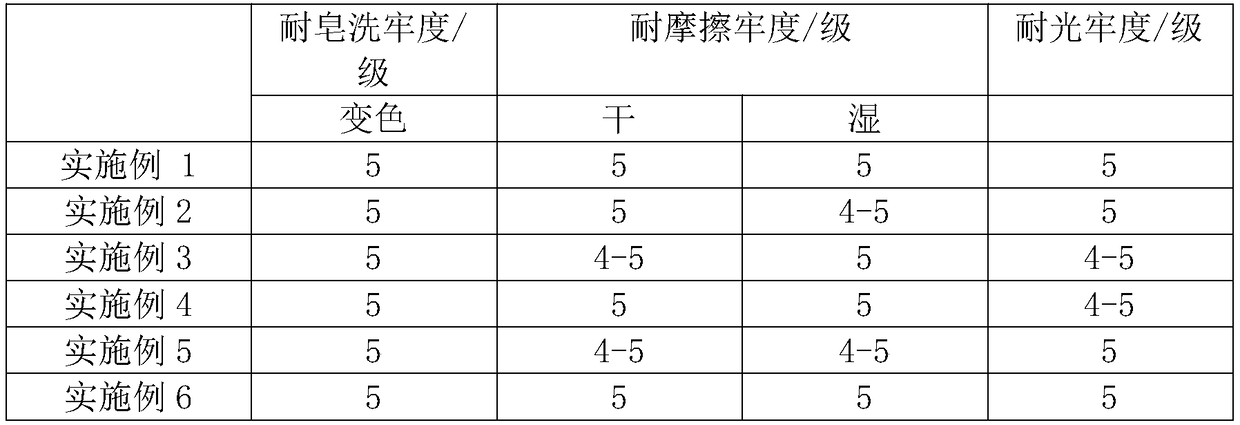

Examples

Embodiment 1

[0026] A method for preparing ink for digital printing based on the modification of boron nitride nanosheets includes the following steps:

[0027] (1) Mix boron nitride powder and isopropanol, ultrasonic treatment at 1000W power for 30min, then centrifuge, collect the precipitate, and dry to prepare boron nitride nanosheets; among them, the amount of isopropanol powder and isopropanol The ratio is 1g:50ml;

[0028] (2) Mix the boron nitride nanosheets, hydrochloric acid solution, and hydrogen peroxide solution uniformly, immerse the nanosheets for 3 hours, filter, wash the boron nitride nanosheets to neutrality, and dry to obtain activated boron nitride nanosheets;

[0029] (3) Dissolve the silane coupling agent in ethanol, add activated boron nitride nanosheets, heat up to 60-70°C, stir and react for 30 minutes, cool to room temperature after the reaction, filter, and dry the solid to obtain modified nitrogen Boron nanosheets; wherein the ratio of the silane coupling agent to acti...

Embodiment 2

[0032] A method for preparing ink for digital printing based on the modification of boron nitride nanosheets includes the following steps:

[0033] (1) Mix boron nitride powder and isopropanol, ultrasonic treatment at 1000W power for 120min, then centrifuge, collect the precipitate, and dry to prepare boron nitride nanosheets; among them, the amount of isopropanol powder and isopropanol The ratio is 1g: 100ml;

[0034] (2) Mix the boron nitride nanosheets, hydrochloric acid solution, and hydrogen peroxide solution uniformly, immerse for 7 hours, filter, wash the boron nitride nanosheets to neutrality, and dry to prepare activated boron nitride nanosheets;

[0035] (3) Dissolve the silane coupling agent in ethanol, add activated boron nitride nanosheets, heat to 60-70°C, stir and react for 60 minutes, cool to room temperature after the reaction, filter, and dry the solid to obtain modified nitrogen Boron fluoride nanosheets; wherein the dosage ratio of silane coupling agent and activ...

Embodiment 3

[0038] A method for preparing ink for digital printing based on the modification of boron nitride nanosheets includes the following steps:

[0039] (1) Mix boron nitride powder and isopropanol, ultrasonic treatment at 1000W power for 50min, then centrifuge, collect the precipitate, and dry to prepare boron nitride nanosheets; among them, the amount of isopropanol powder and isopropanol The ratio is 1g: 60ml;

[0040] (2) Mix the boron nitride nanosheets, the hydrochloric acid solution, and the hydrogen peroxide solution uniformly, immerse the nanosheets for 4 hours, filter, and wash the boron nitride nanosheets to neutrality and dry to obtain activated boron nitride nanosheets;

[0041] (3) Dissolve the silane coupling agent in ethanol, add activated boron nitride nanosheets, heat up to 60-70°C, stir and react for 40 minutes, cool to room temperature after the reaction, filter, and dry the solid to obtain modified nitrogen Boron nanosheets; wherein the ratio of the silane coupling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com