Closed loop environmental protection straw biomechanical pulping process

A technology of straw biological and mechanical method, which is applied in the direction of using microorganism/enzymatic cellulose treatment, finely divided raw material pretreatment, textile and papermaking, etc., which can solve the problems of high yield, pollution, low energy consumption, etc., and achieve pulping The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

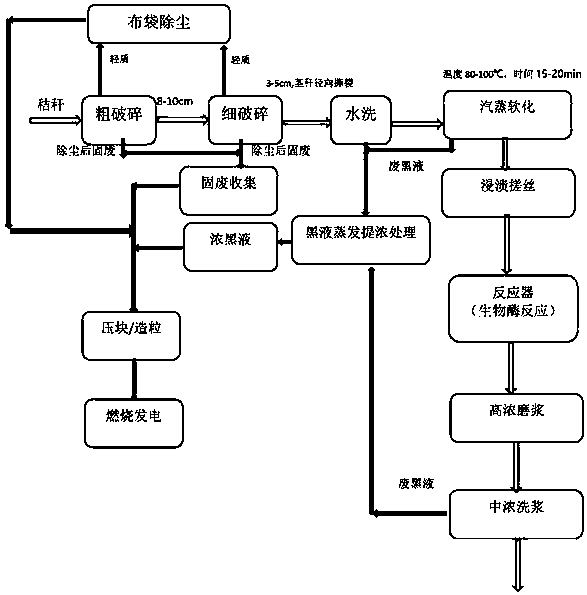

[0024] The closed-loop environment-friendly straw biomechanical pulping process of the present invention combines biotechnology and mechanical technology, uses straw as a raw material, and replaces chemical reaction with biotransformation.

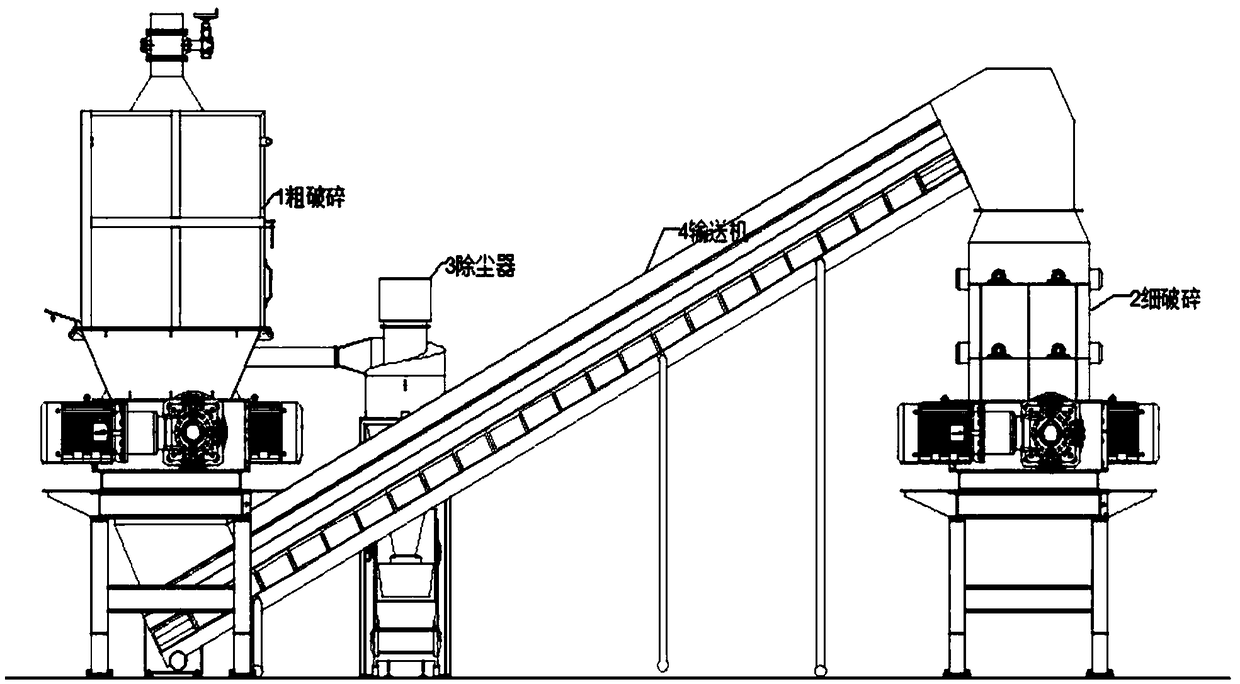

[0025] The pulping process of the present invention comprises: (1) the straw is subjected to rough crushing treatment, and the straw is cut into 8-10cm long coarse material;

[0026] (2) Coarse materials are finely crushed, cut into 3-5cm long fine materials, and the stalks are torn open radially;

[0027] (3) Carry out water washing treatment to aforementioned fine material, remove the silt in the raw material; Dust.

[0028] (4) fine material is carried out steam softening treatment;

[0029] (5) The fine material is impregnated with liquid medicine and scoured into coarse fiber;

[0030] (6) Bio-enzyme treatment is carried out in the bioreactor, and the non-fibrous organic matter in the raw material is oriented to be reacted by the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com