Vibration test platform for deep hole processing

A technology for processing vibration and test platforms, which is applied in vibration testing, testing of machines/structural components, measuring devices, etc. It can solve the problems of difficult control of drill pipe machining accuracy, difficult realization of test conditions, and large volume, and achieve the expansion of parameters. The effect of adjusting the range, reducing the test cost, and compacting the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

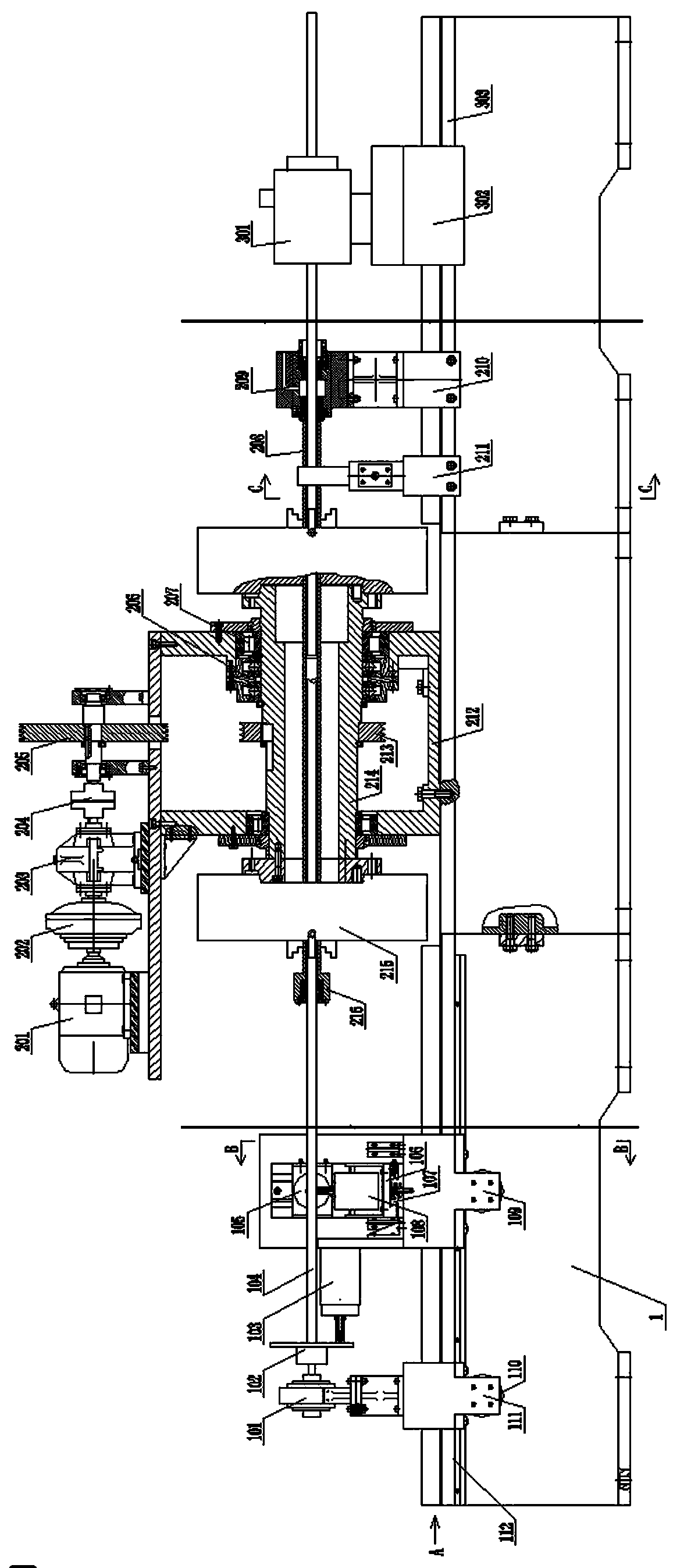

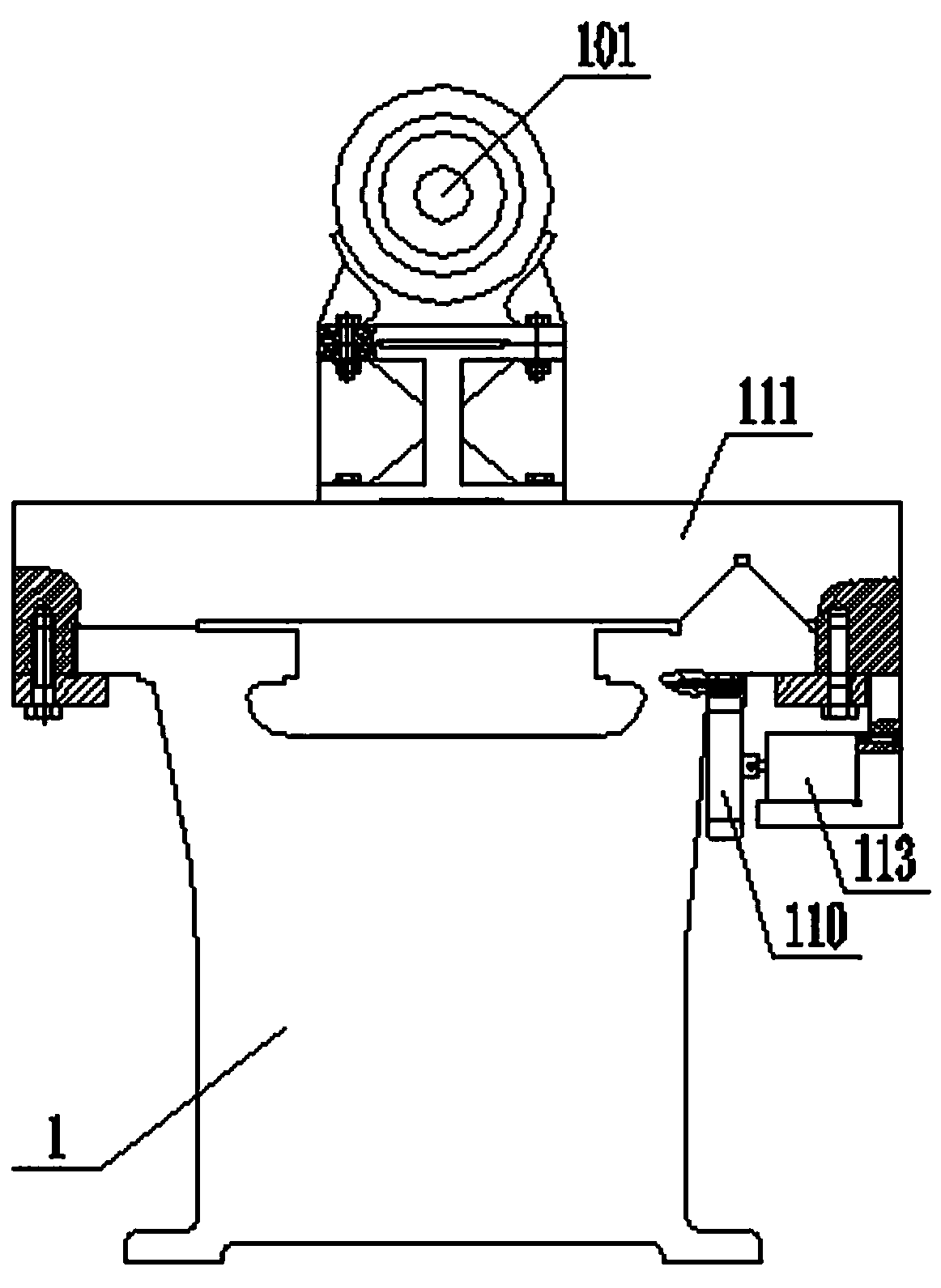

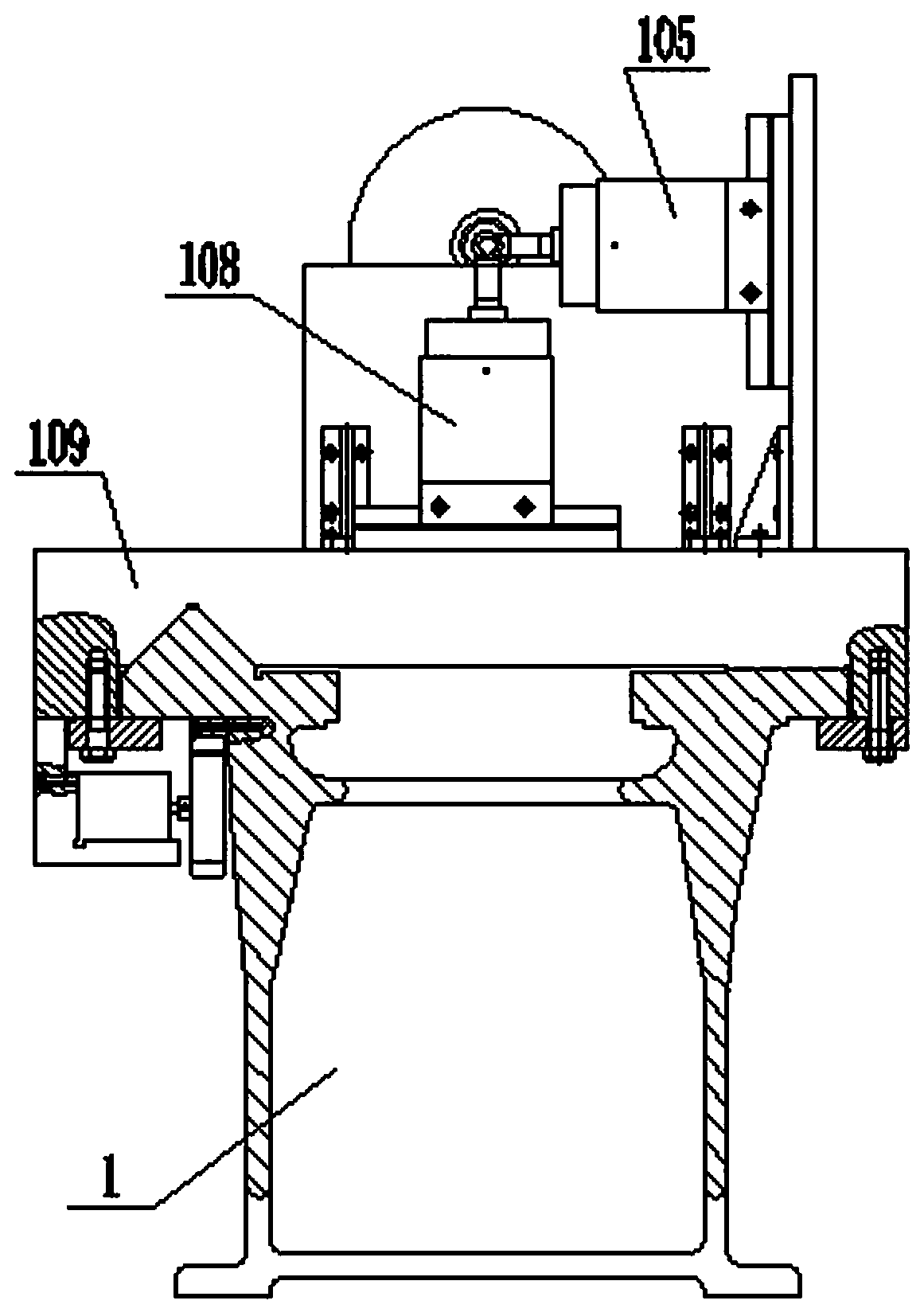

[0023] like Figure 1 to Figure 4 As shown, the present invention includes a machine tool 1, on which an excitation module, an intermediate module and a feed module 302 are sequentially installed from left to right;

[0024] The vibration excitation module includes a left slide rail 112 arranged on the machine tool 1. The left slide rail 1012 is arranged along the left-right direction, and a first base 111 and a second base 110 are slidably connected to the left slide rail 1012. The base 111 is fixed with a torsional vibrator 101, the output shaft of the torsional vibrator 101 is connected with an expansion sleeve coupling 102 for coaxially connecting the drill pipe 104, and a first mode exciter is fixed on the second base 109. vibrator 103, the second mode exciter 108 and the third mode exciter 105, the ejector pin of the first mode vibrator 103 is arranged along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com