Anti-interference cable with electromagnetic shielding capability

A technology of electromagnetic shielding and capacity, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as difficult to meet market demand, poor electromagnetic shielding effect of cables, etc., and achieve excellent shielding effect, high dielectric constant, and good shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

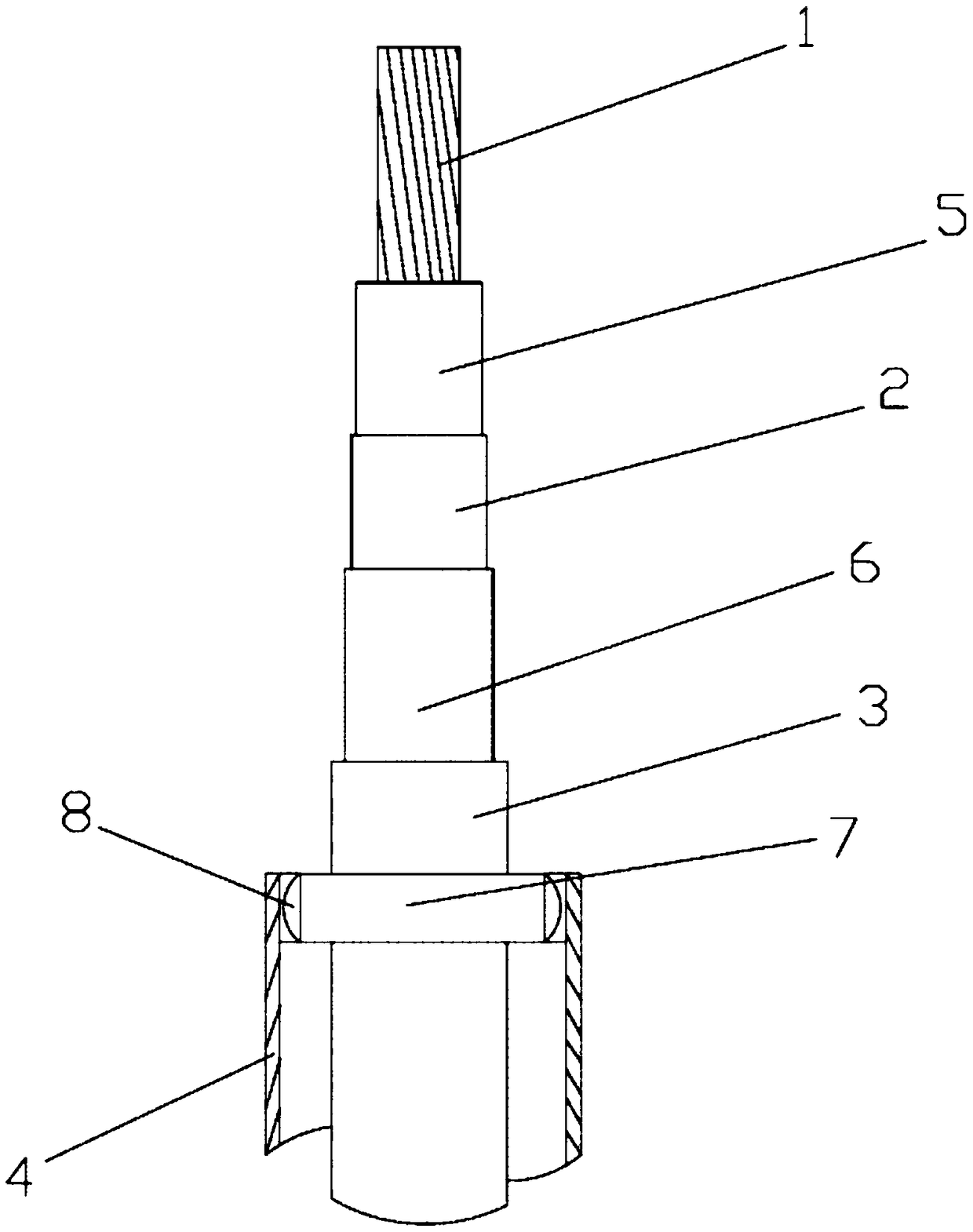

Image

Examples

Embodiment 1

[0041] In this embodiment, an electromagnetic shielding polyester fiber has a polyester fiber body, wherein an Ag-Ag composite film and a Cu film are sequentially arranged on the surface of the polyester fiber body from inside to outside.

[0042] The preparation process of the electromagnetic shielding polyester fiber is:

[0043] S1. Clean the polyester fiber body

[0044] The polyester fiber body is cleaned by ultrasonic method, and after cleaning, the polyester fiber body is dried;

[0045] S2, magnetron sputtering Ag film

[0046] Put the polyester fiber body into the magnetron sputtering apparatus and evacuate to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter the Ag film. After the sputtering is completed, the polyester fiber body Take it out and blow it with nitrogen gas;

[0047] Wherein, the thickness of desc...

Embodiment 2

[0060] In this embodiment, an electromagnetic shielding polyester fiber has a polyester fiber body, wherein an Ag-Ag composite film and a Cu film are sequentially arranged on the surface of the polyester fiber body from inside to outside.

[0061] The preparation process of the electromagnetic shielding polyester fiber is:

[0062] S1. Clean the polyester fiber body

[0063] The polyester fiber body is cleaned by ultrasonic method, and after cleaning, the polyester fiber body is dried;

[0064] S2, magnetron sputtering Ag film

[0065] Put the polyester fiber body into the magnetron sputtering apparatus and evacuate to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter the Ag film. After the sputtering is completed, the polyester fiber body Take it out and blow it with nitrogen gas;

[0066] Wherein, the thickness of desc...

Embodiment 3

[0079] In this embodiment, an electromagnetic shielding polyester fiber has a polyester fiber body, wherein an Ag-Ag composite film and a Cu film are sequentially arranged on the surface of the polyester fiber body from inside to outside.

[0080] The preparation process of the electromagnetic shielding polyester fiber is:

[0081] S1. Clean the polyester fiber body

[0082] The polyester fiber body is cleaned by ultrasonic method, and after cleaning, the polyester fiber body is dried;

[0083] S2, magnetron sputtering Ag film

[0084] Put the polyester fiber body into the magnetron sputtering apparatus and evacuate to 1.5×10 -5 Pa, turn on the argon gas, adjust the slide valve so that the pressure is between 1.5 and 5.0 Pa, turn on the sample autobiography program, pre-sputter for 15 minutes, and then magnetron sputter the Ag film. After the sputtering is completed, the polyester fiber body Take it out and blow it with nitrogen gas;

[0085] Wherein, the thickness of desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com