Low-clamping protection device structure and manufacturing method thereof

A technology for protecting devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of IPP current capability decline, surge anti-surge capability, and high dissipation power, so as to reduce clamping voltage, increasing current capability, increasing the effect of inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0040] The embodiment of the present invention takes a P-type unidirectional low-capacitance TVS device as an example, the first conductivity type is P-type, and the second conductivity type is N-type.

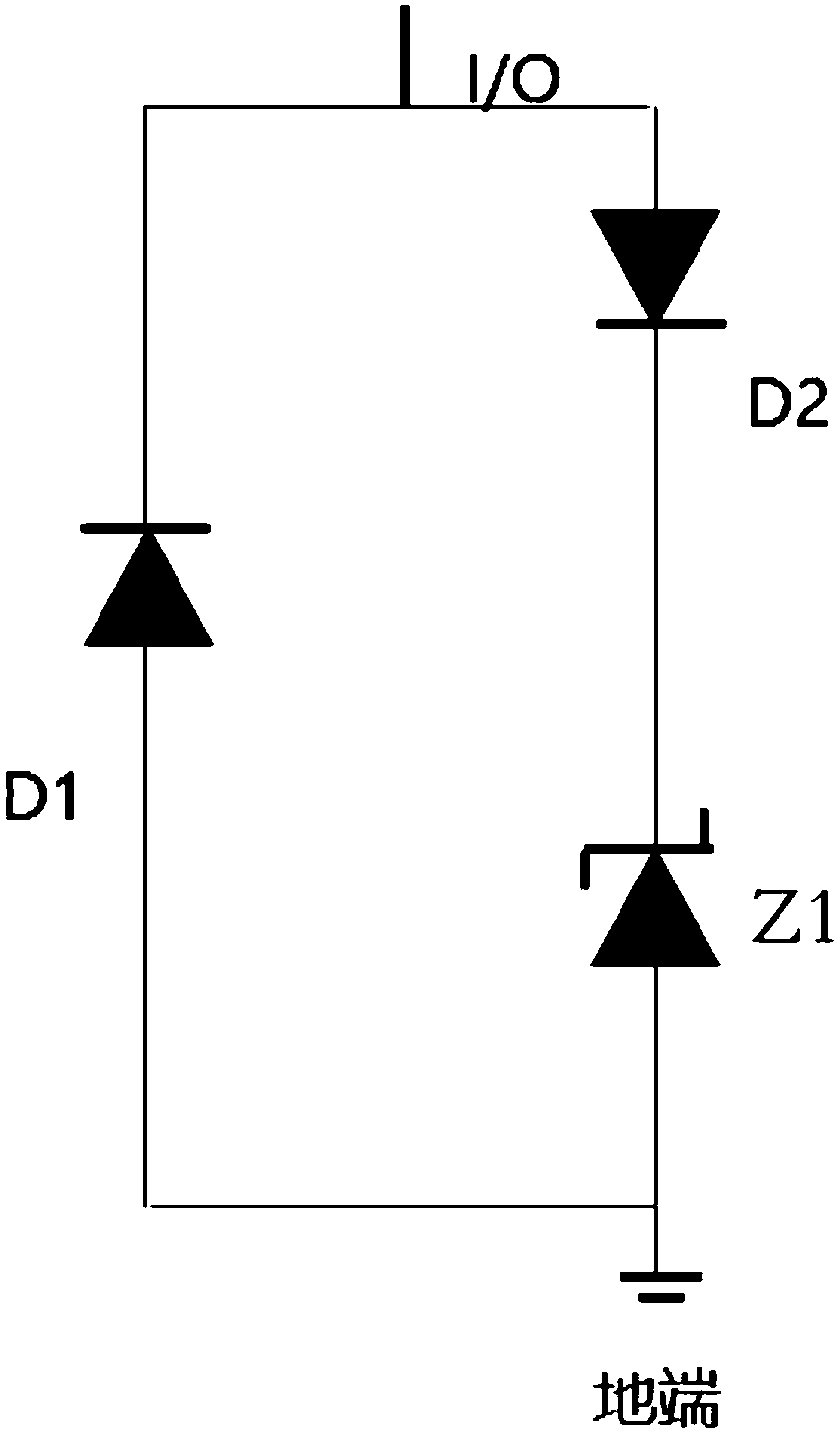

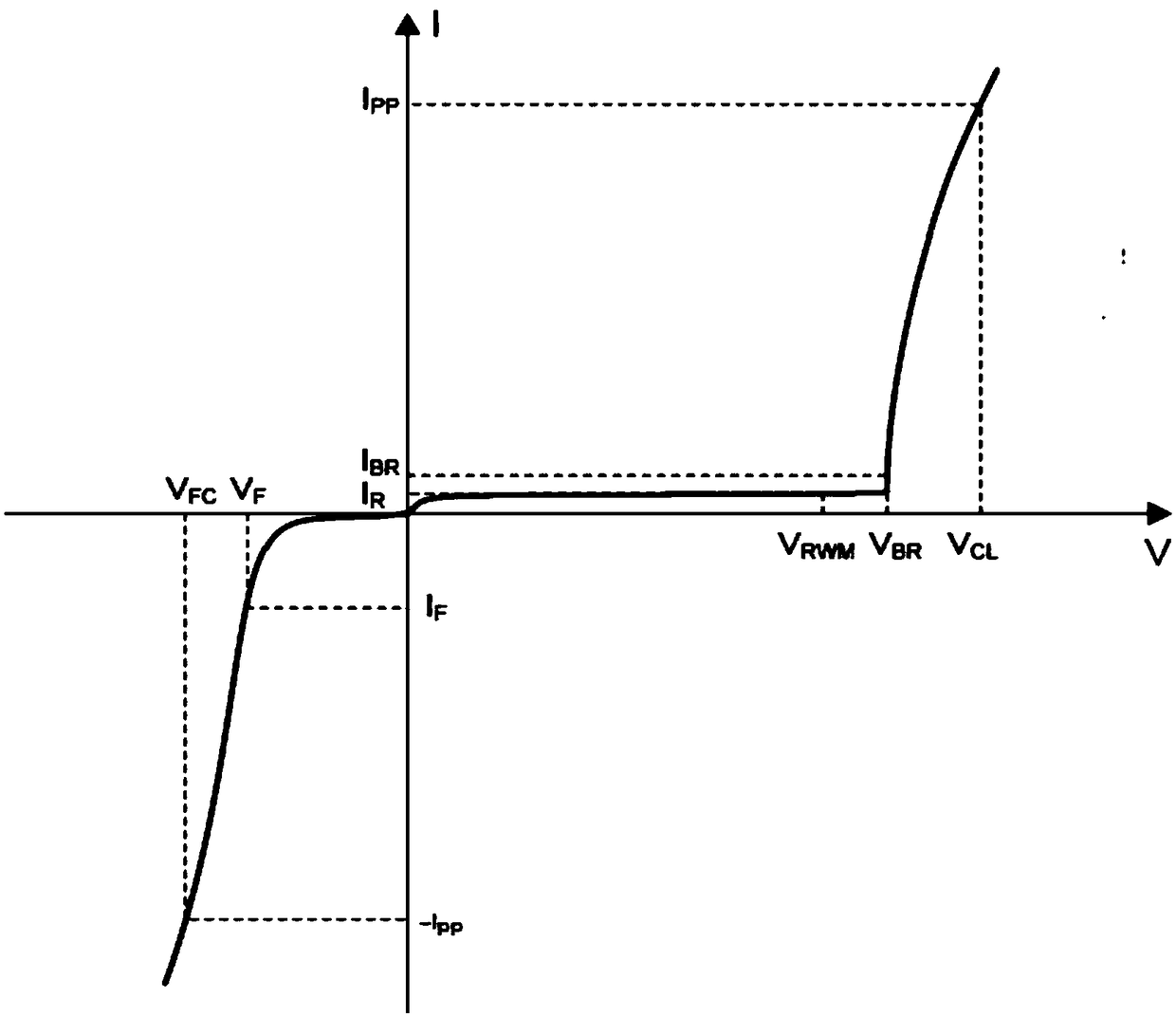

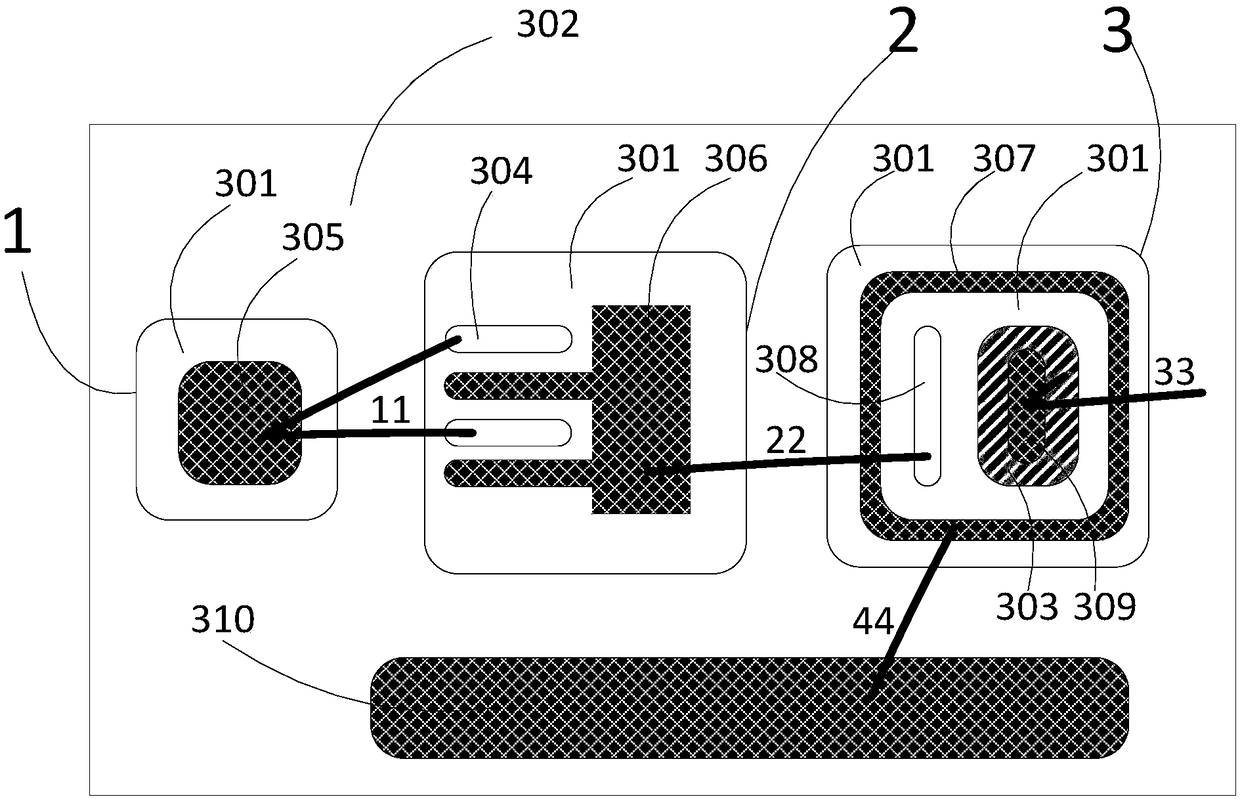

[0041] Such as image 3with Figure 5 As shown, a low-clamp protection device structure includes a P-type substrate 101 and an N-type epitaxial layer 301 located on the P-type substrate 101. It is characterized in that the device is arranged in the N-type epitaxial layer 301. A P-type isolation structure 302 divided into three regions, the P-type isolation structure 302 extending from the surface of the N-type epitaxial layer 301 into the P-type substrate 101;

[0042] A low-capacitance diode D1 for forming a device structure is provided in the first area 1, a low-capacitance diode D2 for forming a device structure is provided in the second area 2, and a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com