CO2-enriched amine solution regeneration energy consumption reducing novel catalytic desorber

A technology of amine solution and desorption tower, which is applied in the field of new catalytic desorption tower, can solve the problems of small gas-liquid-solid three-phase contact area, catalyst utilization efficiency, low efficiency of catalytic desorption system, poor gas-liquid mass transfer performance, etc., and achieve catalytic desorption Excellent performance, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

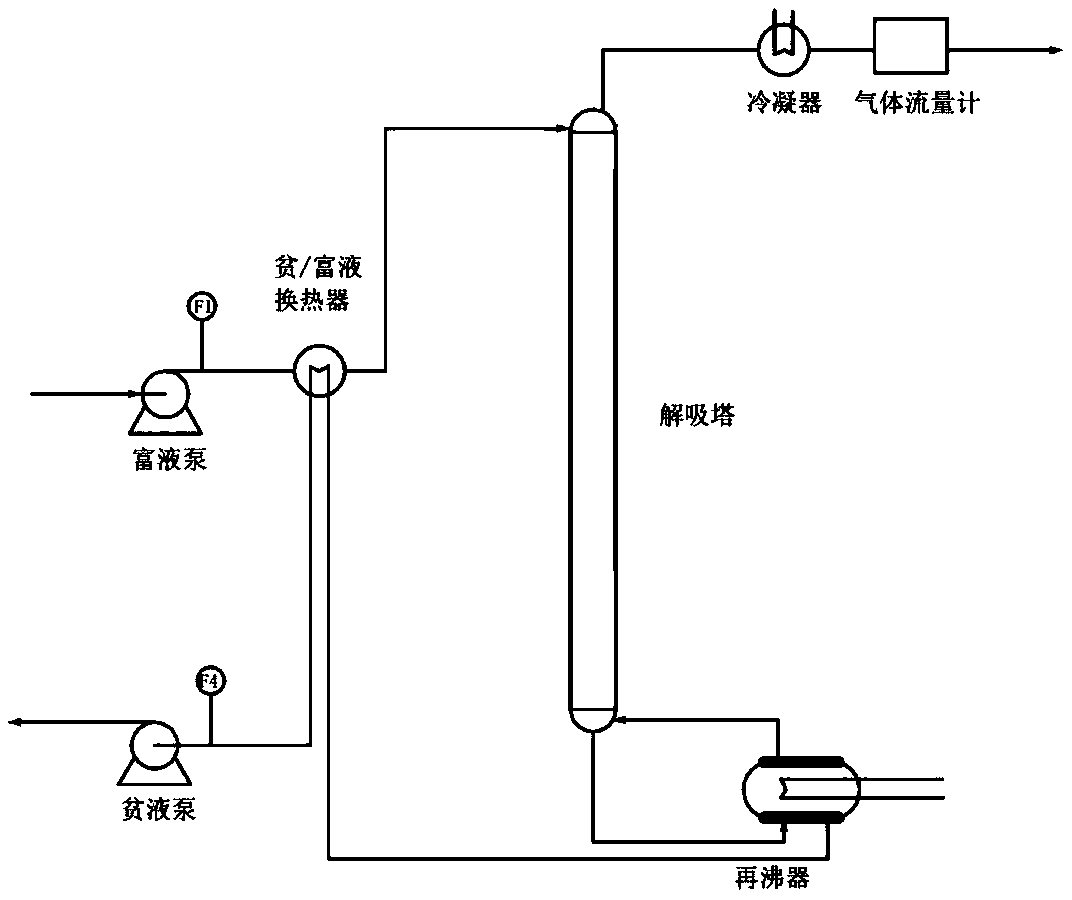

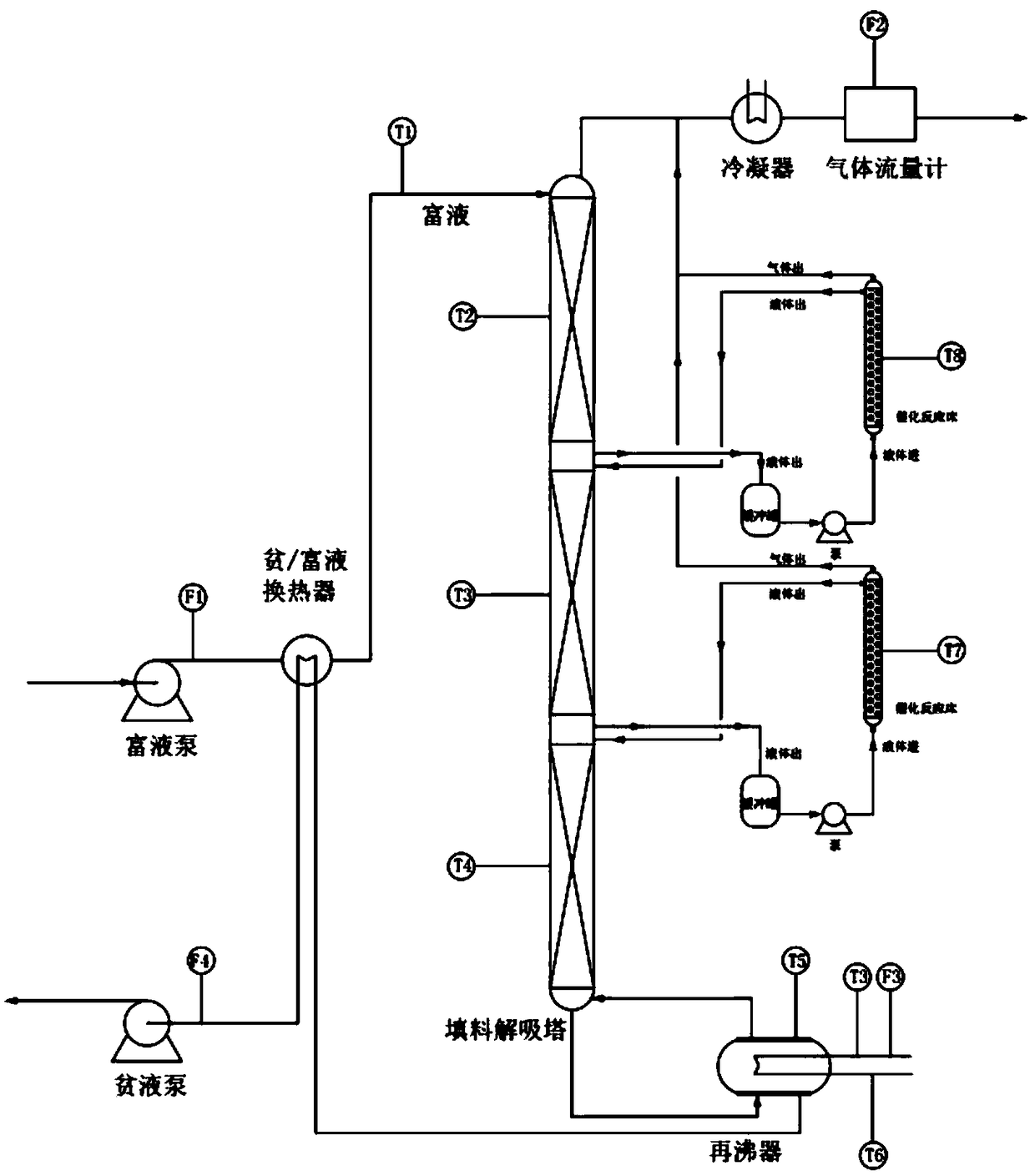

Method used

Image

Examples

Embodiment 1

[0027] The catalytic desorption device of the present invention is used to carry out catalytic desorption of 5M monoethanolamine (MEA) with a rich liquid load of 0.5mol / mol amine. The composition of the catalytic desorption tower is as follows, the tower body is made of stainless steel, the inner diameter of the tower is 35mm, the packing height is 0.6m, and the packing is structured packing; the height of the two catalyst reactors is 0.3m, and the mass ratio of the catalyst to the amine solution is 1 / 80. The solid acid catalyst used is HZSM-5, γ-Al 2 o 3 And SAPO-34 molecular sieve catalyst. The heating medium is heat conduction oil, the desorption temperature is 95°C, and the solution flow rate is 6m 3 / m 2 .

[0028] Solvent desorption energy consumption (Q reg , kJ / kg CO 2 ) is calculated from two parts, that is, the reboiler heat load (H reb ,kJ / h) and CO 2 Gas mass flow rate (m CO2 , kg / h) ratio.

[0029]

[0030] Among them, H loss : System energy loss, kJ...

Embodiment 2

[0043] Use the catalytic desorption device of the present invention to the 6M monoethanolamine (MEA) and 4-(diethylamino)-2-butanol (DEAB) mixed amine solution (molar ratio is 5 : 1) Carry out catalytic desorption, for comparative study, carry out blank desorption (that is, rich amine solution does not flow through catalytic reactor) to the rich solution loading is 0.5mol / mol amine5M MEA. Desorption tower structure is identical with embodiment 1. The solid acid catalyst used is HZSM-5, γ-Al 2 o 3 and HZSM-5 / γ-Al 2 o 3 mixed catalyst. The heating medium is tap water, the desorption temperature is set at 95°C, and the solution flow rate is 6m 3 / m 2 . Solvent desorption energy consumption (Q reg , kJ / kg CO 2 ) is calculated from two parts, that is, the reboiler heat load (H reb ,kJ / h) and CO 2 Gas mass flow rate (m CO2 , kg / h) ratio, its calculation method is the same as example 1.

[0044] The experimental results show that each catalyst can greatly reduce the enri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com